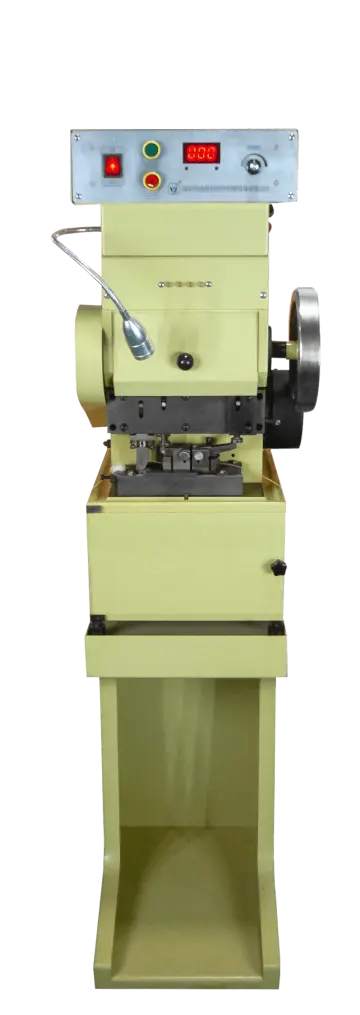

All-in-one jewelry laser welding machine

Jewelry laser spot welding machine, also known as gold and silver jewelry laser spot welding machine or small laser spot welding machine, is an instrument and equipment used for welding gold and silver jewelry, belonging to the category of spot welding machines. This device uses high-energy laser pulses to locally heat small areas of materials, forming a molten pool through thermal conduction to achieve welding. It is widely used in industries such as aviation, aerospace, sports goods, jewelry, golf heads, medical equipment, aluminum alloy dentures, instruments, electronics, mechanical processing, automobiles, etc. for hole filling, spot welding seam patterns, embedded parts, and claw foot welding. The main applicable materials include platinum, K gold, silver, titanium gold, stainless steel, copper, aluminum and their alloys.

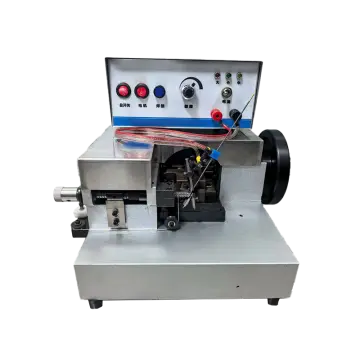

100W Mini jewelry laser welding machine

Jewelry laser welding machine is mainly used for spot welding, seam welding, and inlay welding of precision metal parts such as gold and silver jewelry, jewelry, and watches. This device uses high-energy laser pulses to locally heat small areas of materials, forming a molten pool through thermal conduction to achieve welding. It is widely used in industries such as aviation, aerospace, sports goods, jewelry, golf heads, medical equipment, aluminum alloy dentures, instruments, electronics, mechanical processing, automobiles, etc. for hole filling, spot welding seam patterns, embedded parts, and claw foot welding. Support precision welding of platinum, K-gold, silver, titanium gold, stainless steel, copper, aluminum and their alloy materials, especially suitable for repairing holes, spot welding sand holes and claw foot parts of gold and silver jewelry.

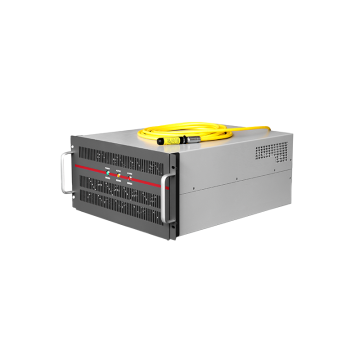

150W QCW fiber laser welding machine

QCW fiber laser core selection range:from 14um to 200um a variety of fiber core selection,cope with different materials,choose the most fuitable fiber;Optical fiber core pair output the diameter of the spot has a direct effect.Under the same output energy,the size of the spot is positively correlated with the molten pool.At the same time,the smaller the spot,the stronger the puncture force,the deeper the melting depth,different fibers the core can be selected according to different welding requirements with appropriate laser.

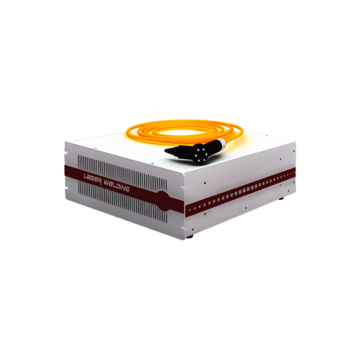

100W QCW fiber laser welding machine

QCW fiber laser core selection range:from 14um to 200um a variety of fiber core selection,cope with different materials,choose the most fuitable fiber;Optical fiber core pair output the diameter of the spot has a direct effect.Under the same output energy,the size of the spot is positively correlated with the molten pool.At the same time,the smaller the spot,the stronger the puncture force,the deeper the melting depth,different fibers the core can be selected according to different welding requirements with appropriate laser.

60W QCW fiber laser welding machine-copy

QCW fiber laser core selection range:from 14um to 200um a variety of fiber core selection,cope with different materials,choose the most fuitable fiber;Optical fiber core pair output the diameter of the spot has a direct effect.Under the same output energy,the size of the spot is positively correlated with the molten pool.At the same time,the smaller the spot,the stronger the puncture force,the deeper the melting depth,different fibers the core can be selected according to different welding requirements with appropriate laser.

300W QCW fiber laser welding machine-...

QCW fiber laser core selection range:from 14um to 200um a variety of fiber core selection,cope with different materials,choose the most fuitable fiber;Optical fiber core pair output the diameter of the spot has a direct effect.Under the same output energy,the size of the spot is positively correlated with the molten pool.At the same time,the smaller the spot,the stronger the puncture force,the deeper the melting depth,different fibers the core can be selected according to different welding requirements with appropriate laser.

200W jewelry laser welding machine

Jewelry laser welding machine uses laser deposition welding technology, which uses laser high thermal energy and centralized fixed-point welding technology. Surface heat is transferred and diffused internally. By controlling parameters such as laser pulse width, energy, peak power, and repetition frequency, the workpiece is melted to form a specific molten pool. Due to its unique advantages, it is widely used in the processing of gold and silver jewelry and the welding of small and medium-sized parts.

80W jewelry laser welding machine

Adopting a pulse laser power control system; The charging circuit adopts L-C resonant charging, and the energy storage adopts a capacitor inductor energy storage network to supply power to the lamp. The control circuit is based on ARM microprocessor, which can adjust the output energy and repetition frequency of the power supply; The system has multiple protections to ensure emergency disconnection of the main power supply in abnormal situations.

Lily

Lily Jason wong

Jason wong