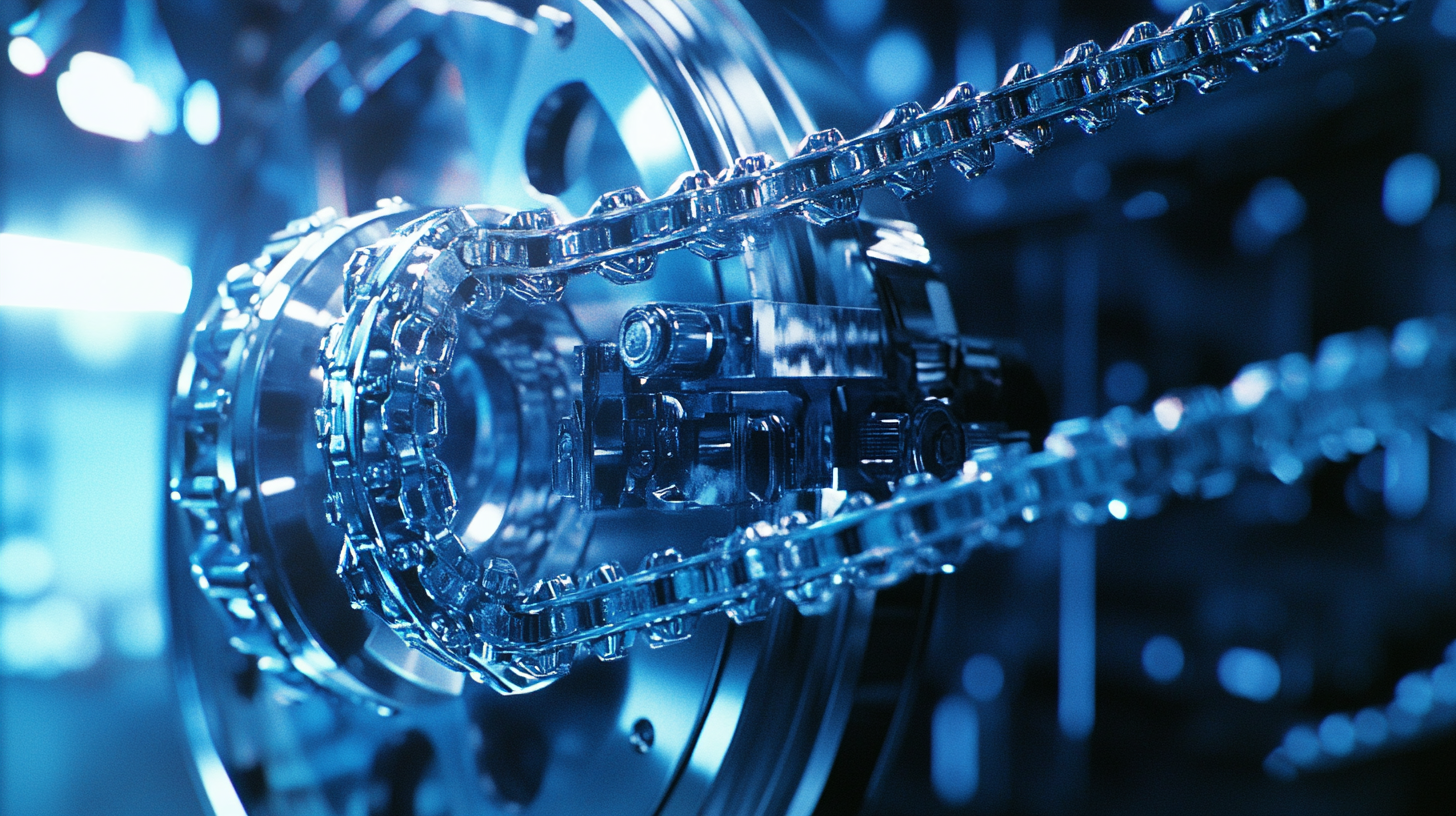

In today's competitive manufacturing landscape, the quest for efficiency and productivity is paramount, particularly in industries such as jewelry and industrial equipment where chains are essential components. Innovative applications of the Automatic Chain Making Machine are transforming traditional production methods, allowing manufacturers to meet growing demands while reducing labor costs. According to a recent industry report by MarketsandMarkets, the global automated machinery market is projected to reach $300 billion by 2025, driven largely by advancements in automation and machine efficiency. The Automatic Chain Making Machine exemplifies this trend, as it not only enhances production speed but also ensures consistent quality and precision in chain manufacturing. As businesses continue to seek ways to optimize their operations, understanding the numerous benefits and applications of this advanced machinery will be crucial for staying competitive in the market.

The modern manufacturing landscape continues to evolve, and the adoption of automatic chain making machines has become a game-changer in optimizing production processes. These machines not only enhance the efficiency of chain production but also improve consistency and reduce labor costs. By automating the intricate processes involved in chain manufacturing, companies can significantly increase output while maintaining high-quality standards.

The benefits of automatic chain making machines are particularly evident in the electric motor industry, where precision and reliability are paramount. As electric motors are integral to various applications, ensuring that components such as chains are produced with impeccable accuracy is crucial. These machines utilize advanced technology to streamline operations, enabling manufacturers to meet the growing demand without compromising on performance. The transformation brought about by automatic chain making machines is paving the way for a more productive and sustainable future in manufacturing.

The integration of advanced technologies in manufacturing processes is crucial for enhancing efficiency, particularly in automatic chain production. The latest automatic chain making machines feature innovative designs that prioritize energy efficiency, speed, and precision. Key attributes such as automated quality control systems and adaptive machinery contribute significantly to maximizing production output while minimizing waste. This shift towards smart manufacturing not only streamlines operations but positions companies to respond swiftly to market demands.

Furthermore, the rise of industrial models that leverage artificial intelligence and digital technologies is transforming traditional production lines into smart factories. These innovations allow for real-time monitoring and adjustments, ensuring a continuous flow of high-quality products. As the manufacturing sector embraces these cutting-edge tools, the potential for achieving "new quality productivity" becomes increasingly evident, marking a pivotal transition towards a more competitive industrial landscape. This transformation is vital for companies seeking to maintain relevance in a rapidly evolving global market.

The recent advancements in automation are reshaping the landscape of manufacturing, particularly in the production of chains. Innovative techniques are at the forefront of maximizing output, and the latest automatic chain making machines are leading the charge. These machines incorporate cutting-edge technology, enabling manufacturers to streamline operations, reduce labor costs, and enhance precision. By automating various stages of the chain-making process, companies can significantly boost their efficiency, responding to market demands with remarkable agility.

At the cippe2025 exhibition, a spotlight was shone on the digital transformation within the oil and gas equipment manufacturing sector. Attendees witnessed a variety of smart drilling systems and digital oilfield solutions designed to optimize resource management. Such technologies not only enhance operational efficiency but also pave the way for sustainability in resource extraction. As the industry adopts automation, the application of these innovative techniques will likely usher in a new era of productivity, setting benchmarks for excellence and reliability. By embracing these advancements, manufacturers can remain competitive and deliver high-quality products that meet the evolving needs of the market.

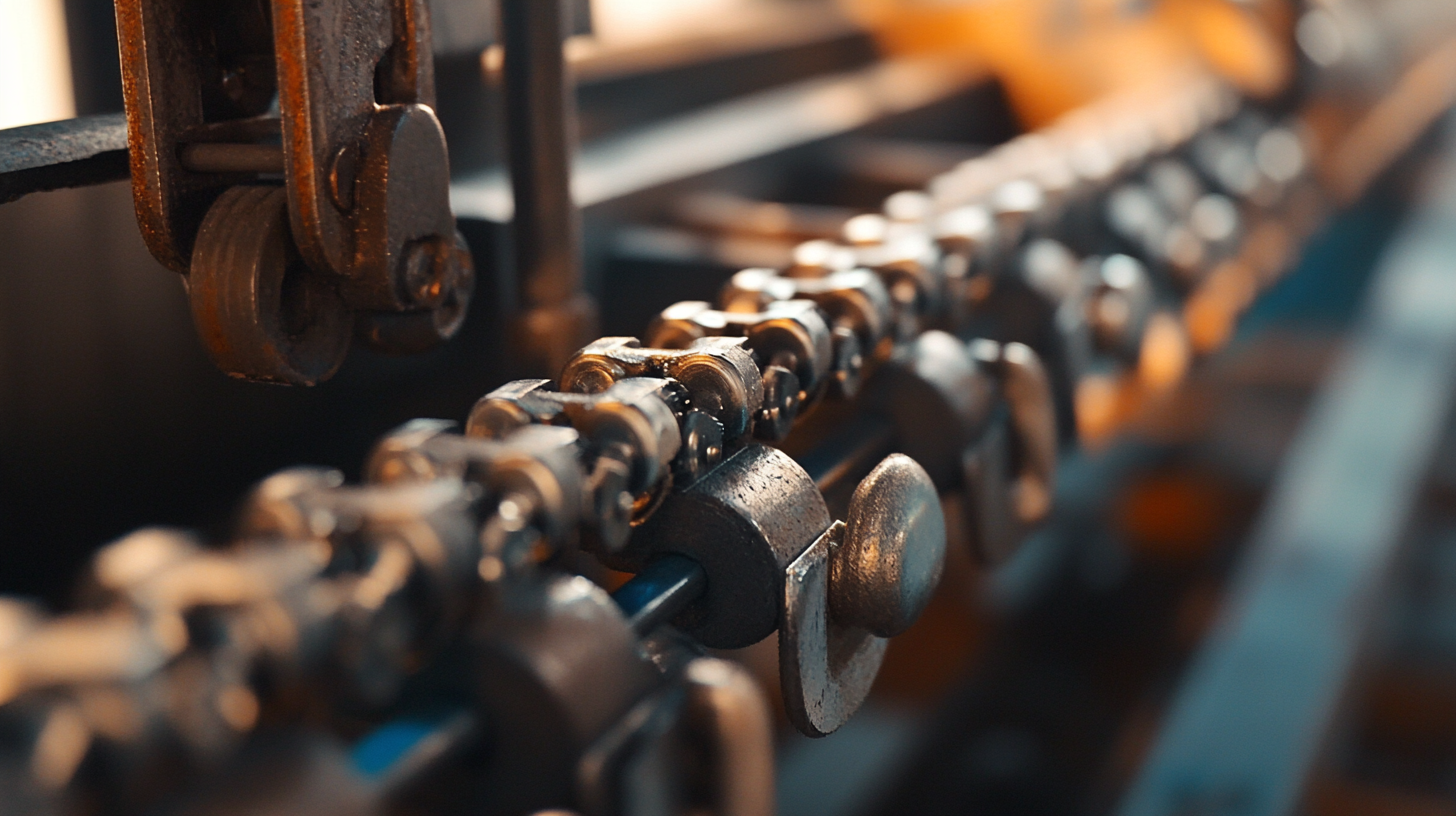

In the realm of jewelry manufacturing, the implementation of advanced automatic chain making machines has significantly transformed production efficiency. Case studies from leading chain makers reveal how these innovations facilitate streamlined operations, drastically reducing labor costs while boosting output. For instance, a renowned jewelry manufacturer in Italy adopted an automatic chain making machine that increased their daily production from 500 to over 2,000 chains. The integration of cutting-edge technology not only accelerated the manufacturing process but also enhanced the precision and quality of every piece produced.

Another compelling case comes from an enterprise based in the United States that faced challenges in meeting growing consumer demands. By leveraging automatic chain making solutions, they revitalized their production line, adapting to various designs without sacrificing speed. This flexibility allowed them to cater to a broader market, ultimately increasing their revenue by 30% within six months. The success stories of these companies highlight how embracing innovation in chain making can lead to remarkable improvements in efficiency, quality, and profitability, setting a new standard in the jewelry manufacturing industry.

This chart illustrates the production output of various automatic chain making machines, showcasing their efficiency in units per hour. The data presented reflects real implementations of advanced chain making solutions, highlighting the advancements in manufacturing technology.

The future trends in automatic chain manufacturing are deeply intertwined with the broader industrial automation landscape, predicted to witness significant growth in the coming years. According to the latest reports, the global logistics robot market is set to surge from 71.1 billion USD in 2022 to an astounding 210.1 billion USD by 2029, representing a compound annual growth rate (CAGR) of 16.7%. This growth emphasizes the increasing demand for automation solutions in manufacturing, including advanced chain-making machines that enhance productivity and streamline operations.

Moreover, the automotive industry's transformation is a pivotal force driving innovations in chain manufacturing. With the rapid advancements in smart vehicle technology, the automotive sector anticipates five key trends by 2025, such as the rise of electric vehicles and autonomous driving, combined with 5G integration. These changes not only reshape consumer mobility but also create new opportunities for manufacturers to adopt cutting-edge automatic chain solutions that meet the evolving demands of smart automotive systems. The convergence of these trends reflects a broader Industry 4.0 movement, where automated processes and data-driven insights are inescapably linked to future manufacturing success.

| Application | Efficiency Improvement (%) | Automation Level | Future Trend (2025) |

|---|---|---|---|

| High-Volume Production | 30% | Fully Automated | Increased AI Integration |

| Customized Chain Designs | 25% | Semi-Automated | Advanced CAD Integration |

| Rapid Prototyping | 40% | Fully Automated | Increased Speed and Precision |

| Mass Production Control | 20% | Fully Automated | Enhanced IoT Capabilities |

| Quality Control Assurance | 15% | Semi-Automated | Smart Sensors Integration |