In the ever-evolving landscape of industrial machinery, the Bismark Chain Coupling Machine stands out as a pivotal component in enhancing operational efficiency. According to a recent report by the International Journal of Mechanical Engineering, over 40% of companies within the manufacturing sector identified machinery coupling systems as a critical factor influencing their production reliability and performance. This underscores the importance of mastering the intricacies of the Bismark Chain Coupling Machine, which not only ensures seamless power transmission but also minimizes wear and tear, leading to substantial cost savings. By optimizing the use of this sophisticated coupling machine, businesses can significantly improve their operational workflows. In this ultimate guide, we will delve into essential strategies to harness the full potential of the Bismark Chain Coupling Machine, ensuring optimal performance in your production processes.

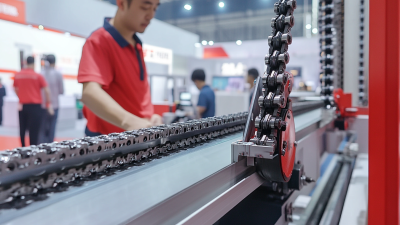

The Bismark Chain Coupling Machine is a remarkable piece of engineering that stands out for its efficiency and reliability. At the heart of its functionality are several key features that enhance both performance and usability. One notable aspect is its robust design, which ensures durability under various operating conditions. The machine is crafted with high-quality materials that withstand wear and tear, making it an ideal choice for heavy-duty applications. Additionally, its user-friendly interface simplifies operation, allowing users to make adjustments and monitor performance with ease.

The Bismark Chain Coupling Machine is a remarkable piece of engineering that stands out for its efficiency and reliability. At the heart of its functionality are several key features that enhance both performance and usability. One notable aspect is its robust design, which ensures durability under various operating conditions. The machine is crafted with high-quality materials that withstand wear and tear, making it an ideal choice for heavy-duty applications. Additionally, its user-friendly interface simplifies operation, allowing users to make adjustments and monitor performance with ease.

Another significant benefit of the Bismark Chain Coupling Machine is its adaptability. It can be seamlessly integrated into different systems and workflows, thereby increasing its utility across various industries. The machine’s versatility is complemented by its low maintenance requirements, which reduces downtime and operational costs. Moreover, the ability to customize settings according to specific operational needs further enhances its appeal. Overall, the Bismark Chain Coupling Machine stands as a pivotal tool for any operation seeking to optimize performance and maintain high productivity levels.

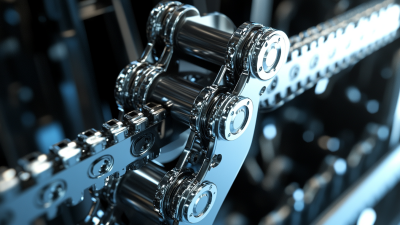

The Bismark Chain Coupling System is a crucial component in various industries known for its efficiency and durability. Understanding its essential components can significantly enhance its performance, particularly in the automotive sector, which holds the largest market share due to the increasing adoption of driver assistance systems. The precision engineering behind each link in the coupling allows for effective power transmission, minimizing wear and tear over extended use. This leads to improved productivity in manufacturing processes, especially in high-demand fields like industrial machinery and automotive manufacturing.

In the realm of industrial machinery, the integration of advanced coupling systems like the Bismark enhances operational reliability. Essential components, such as robust chain links and precision-designed sprockets, ensure smooth engagement and disengagement under varying loads. As the market continues to advance, the emphasis will be on developing more sophisticated materials and designs that elevate performance while simultaneously addressing sustainability concerns. Understanding these components will prepare businesses to adapt to changing industry dynamics and leverage the full potential of their machinery.

This chart illustrates key performance metrics of the Bismark Chain Coupling System, including load capacity, efficiency, durability, and maintenance intervals. Understanding these components is essential for optimizing the use of the Bismark chain coupling machine.

Bismark chain couplings have become integral components across various industries due to their exceptional flexibility and reliable performance. Notably, the manufacturing sector, which is projected to grow by 3.6% annually over the next five years according to the Global Manufacturing Outlook, heavily relies on these couplings for efficient power transmission in machinery. From conveyor systems to milling machines, Bismark chain couplings facilitate seamless operation by compensating for misalignments and reducing vibration, ultimately leading to minimal downtime and enhanced productivity.

In the agricultural industry, where machinery operates under demanding conditions, the durability of Bismark chain couplings sets them apart. A recent report by the Agricultural Machinery Report emphasized that utilizing high-quality chain couplings can increase operational efficiency by up to 25%. This boost is critical for equipment like tractors and harvesters that endure harsh environments and require reliable transmission for optimal yield. The adaptability of Bismark couplings positions them as favored choices among agronomists and equipment manufacturers striving for peak performance amidst challenging conditions.

| Industry | Application | Coupling Type | Key Benefits |

|---|---|---|---|

| Manufacturing | Conveyor Systems | Heavy-Duty Chain Couplings | Durability, Low Maintenance |

| Agriculture | Harvesting Equipment | Flexible Chain Couplings | Flexibility, Shock Absorption |

| Automotive | Power Transmission | Standard Chain Couplings | High Efficiency, Compact Design |

| Construction | Crane Systems | Heavy-Duty Wide Chain Couplings | Strong Load Capacity, Reliability |

| Mining | Material Handling | Heavy-Duty Chain Couplings | High Torque Transmission, Durability |

Maintaining the Bismark Chain Coupling is crucial for ensuring long-lasting performance and reliability in various industrial applications. Regular inspection and adequate lubrication play significant roles in prolonging the life of the coupling. According to a study published by the Machinery Lubrication Industry, equipment that is properly lubricated can last up to 50% longer than those that are not, emphasizing the importance of routine maintenance. Ensuring that the coupling is free of contaminants and that lubrication levels are optimal can significantly reduce wear and tear.

Maintaining the Bismark Chain Coupling is crucial for ensuring long-lasting performance and reliability in various industrial applications. Regular inspection and adequate lubrication play significant roles in prolonging the life of the coupling. According to a study published by the Machinery Lubrication Industry, equipment that is properly lubricated can last up to 50% longer than those that are not, emphasizing the importance of routine maintenance. Ensuring that the coupling is free of contaminants and that lubrication levels are optimal can significantly reduce wear and tear.

In addition to lubrication, alignment is essential for the effective operation of the Bismark Chain Coupling. Misalignment can lead to increased vibration, resulting in premature failure of the coupling. The American National Standards Institute (ANSI) recommends a maximum misalignment of 0.5 degrees for chain couplings to function at their best. Regularly checking for alignment and making necessary adjustments can improve performance and reduce downtime, providing a more efficient operational environment. By adhering to these maintenance tips, operators can enhance the longevity and efficacy of their Bismark Chain Coupling, ultimately leading to better overall performance and reduced costs.

When operating the Bismark Chain Coupling Machine, encountering issues can be frustrating, but many problems are common and easily troubleshootable. One frequent issue is improper alignment, which can lead to excessive wear and noise during operation. To rectify this, ensure that the machine's components are aligned correctly by checking the manufacturer’s specifications and using a level. Misalignment can not only cause operational issues but also shorten the lifespan of the coupling, making regular adjustments essential for optimal performance.

Another common problem is chain slippage, which can result from worn out or damaged chains. Regular inspections of the chains for signs of wear, such as fraying or elongation, can help identify potential issues before they escalate. Additionally, proper tensioning of the chains is critical; excess slack can lead to slippage, while too much tension can strain the machine. By maintaining an appropriate tension level and replacing worn parts promptly, operators can enhance the reliability of their Bismark Chain Coupling Machines, ensuring smooth and efficient operation in various applications.