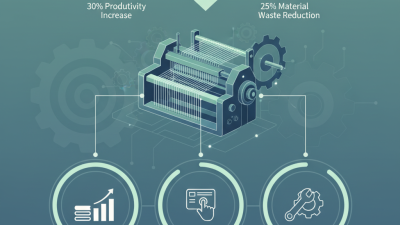

In the rapidly evolving jewelry industry, the adoption of advanced technologies such as CAD CAM Jewelry Machines is redefining the standards of creativity, precision, and efficiency. A recent report by MarketWatch indicates that the global CAD CAM jewelry market is projected to experience a substantial growth rate of over 10% annually, driven by the increasing demand for personalized and bespoke jewelry pieces. As artisans and manufacturers increasingly turn to these machines, they are equipped to produce intricate designs that were once unimaginable, significantly enhancing productivity and reducing material waste.

Dr. Elena Martin, a renowned expert in jewelry manufacturing technology, states, "The integration of CAD CAM Jewelry Machines not only streamlines the production process but also empowers jewelers to push the boundaries of design innovation." This sentiment reflects the broader industry trend, where the fusion of artistry and technology is becoming essential for staying competitive in a market that values both uniqueness and efficiency. With a variety of machines available that cater to different needs and scales of operation, understanding the top choices for 2023 will be crucial for jewelers aiming to leverage the full potential of these cutting-edge tools.

In 2023, the evolution of CAD CAM jewelry machines highlights a shift toward greater precision and efficiency, driven by advancements in technology and user demands. One of the key trends is the integration of artificial intelligence and machine learning, enabling these machines to optimize design processes automatically. This innovation allows for faster prototyping and improved accuracy, reducing the time from concept to finished product. Users are increasingly valuing seamless software integration, which facilitates easier workflows and enhances overall productivity in jewelry design.

Another significant trend is the focus on sustainability and eco-friendly practices within the jewelry manufacturing process. Many new machines are designed to minimize waste and utilize recyclable materials, aligning with the growing consumer demand for environmentally responsible products. Additionally, the adoption of multi-functional machines that can handle a variety of tasks—such as 3D printing and CNC milling—offers jewelers more versatility, allowing for intricate designs and customized pieces with minimal downtime. This evolution not only boosts efficiency but also empowers designers to experiment with new art forms in jewelry creation.

When selecting a CAD CAM jewelry machine, several key features play a crucial role in determining both precision and efficiency. First and foremost, resolution is vital; machines with higher resolution capabilities ensure detailed designs and intricate patterns can be rendered accurately. This is essential for achieving the fine details that are often required in high-end jewelry design. Additionally, the milling speed and cutting methods utilized by the machine can greatly impact workflow efficiency, as faster cutting times can decrease production costs without compromising on quality.

Another important consideration is the software compatibility that comes with these machines. Advanced CAD CAM systems often offer user-friendly interfaces and robust design tools that can streamline the workflow from conceptualization to finished product. Furthermore, an intuitive software setup can enhance the learning curve for new users and provide seamless integration with existing design projects. Other features to evaluate include material versatility, as machines capable of working with various materials—including metals, resins, and wax—give jewelers more creative freedom. Lastly, maintenance requirements and customer support services are essential for ensuring longevity and optimal performance of the machinery over time.

| Machine Model | Max Work Area (mm) | Precision (µm) | Software Compatibility | Cooling System | Price Range ($) |

|---|---|---|---|---|---|

| Model A | 300 x 200 | 5 | CAD/CAM Software X | Water Cooling | 5,000 - 7,000 |

| Model B | 400 x 250 | 4 | CAD/CAM Software Y | Air Cooling | 6,000 - 8,000 |

| Model C | 350 x 300 | 3 | CAD/CAM Software Z | Liquid Cooling | 4,500 - 6,500 |

| Model D | 200 x 150 | 6 | CAD/CAM Software X & Y | Air Cooling | 3,000 - 5,000 |

| Model E | 500 x 300 | 2 | CAD/CAM Software W | Water Cooling | 7,000 - 9,000 |

| Model F | 350 x 200 | 5 | CAD/CAM Software X | Air Cooling | 4,000 - 5,500 |

| Model G | 400 x 300 | 3 | CAD/CAM Software Y | Liquid Cooling | 5,500 - 7,500 |

| Model H | 450 x 250 | 6 | CAD/CAM Software Z | Air Cooling | 3,500 - 4,800 |

| Model I | 500 x 400 | 2 | CAD/CAM Software W & Z | Water Cooling | 8,000 - 10,000 |

| Model J | 225 x 175 | 4 | CAD/CAM Software X | Air Cooling | 2,500 - 3,500 |

When considering the best CAD CAM jewelry machines on the market in 2023, precision and efficiency stand out as critical factors. The comparison of leading models reveals a range of features tailored to meet the diverse needs of jewelers. Although specifications may vary, key attributes such as milling speed, software compatibility, and ease of use consistently impact the user experience and overall production capabilities.

Tips for selecting the right machine for your needs include evaluating the types of materials you intend to work with. Certain machines excel with specific metals or stones, influencing the quality of the final product. Additionally, consider the software’s user interface; intuitive design can drastically lessen the learning curve, allowing you to focus more on creativity and less on technical challenges.

Investing in a CAD CAM machine is not just about initial cost, but also the long-term efficiency it brings to your production line. Pay attention to maintenance and support services offered by the manufacturer, as these elements can significantly affect your machine's longevity and performance. Assessing warranties and customer reviews can further guide your decision-making process, ensuring you choose a machine that grows with your business.

Investing in CAD CAM technology is becoming increasingly vital for jewelers seeking to enhance their precision and efficiency in the competitive jewelry market. According to a report by the Allied Market Research, the global CAD CAM jewelry market was valued at approximately $2.4 billion in 2021 and is projected to reach $5.1 billion by 2030, growing at a compound annual growth rate (CAGR) of 8.9%. This growth highlights the rising demand for advanced technological solutions that not only improve the design process but also streamline production, enabling jewelers to meet customer demands swiftly.

One of the key benefits of integrating CAD CAM technology is the significant increase in design precision. Traditional methods can often lead to human error, whereas CAD software allows for intricate designs to be created with exact specifications. As noted by a survey conducted by the Jewelry Industry Research Association, over 70% of jewelers reported improved design accuracy and reduced production time after adopting CAD CAM systems. Additionally, the ability to visualize and modify designs in a 3D environment leads to faster iterations and enhanced creative possibilities, ultimately ensuring customer satisfaction and loyalty in an industry where personalizations are highly valued.

The future of CAD CAM jewelry equipment is poised for exciting innovations that will significantly enhance the design and manufacturing processes. As technology continues to advance, we can expect developments in software and hardware that improve precision and efficiency. Innovations like artificial intelligence and machine learning are being integrated into CAD programs, enabling designers to create intricate and detailed patterns with minimal manual input. This allows for a more streamlined workflow, reducing the time from concept to production.

Moreover, advancements in 3D printing techniques are set to revolutionize how jewelry is crafted. New materials are being developed that provide greater strength and detail, allowing for the creation of complex designs that were previously unattainable. Additionally, faster printing speeds and more versatile machines will enable jewelers to adapt quickly to changing trends and customer demands, ensuring that they maintain a competitive edge in a rapidly evolving market. As these technologies evolve, they are likely to transform traditional jewelry-making practices into a more dynamic and innovative field.