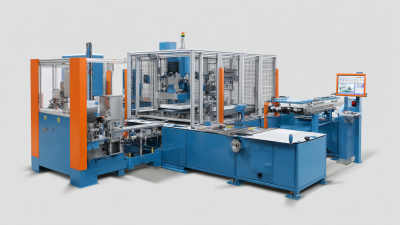

In the dynamic landscape of manufacturing and production, the significance of efficient and dependable machinery cannot be overstated. As industries evolve, the demand for advanced technologies such as the Ball Chain Coupling Machine has surged. These machines play a pivotal role in enhancing operational performance and ensuring seamless coupling processes. Industry expert Dr. Emily Johnson, a leading authority in mechanical engineering, aptly noted, "The performance and reliability of a Ball Chain Coupling Machine are fundamental to the success of modern manufacturing systems."

This statement underscores the importance of selecting the right equipment, especially in a year where optimizing performance is more critical than ever. With vast advancements in technology, 2023 presents a unique opportunity for manufacturers to invest in top-tier ball chain coupling machines that promise improved efficiency, durability, and precision. In this article, we will explore the top five ball chain coupling machines that stand out in the market this year, highlighting their features and the advantages they bring to various industrial applications. By understanding the best options available, businesses can make informed decisions that will ultimately lead to enhanced productivity and a robust manufacturing process.

In 2023, the ball chain coupling machine technology is witnessing significant advancements, aimed at enhancing efficiency and performance across various industries. One of the top trends is the integration of smart technology, enabling these machines to operate with increased automation and reduced human intervention. This shift not only streamlines production processes but also minimizes the risk of errors, contributing to better overall output quality.

Additionally, manufacturers are focusing on energy efficiency, developing machines that consume less power while delivering optimal performance. This is particularly important as industries worldwide strive to meet sustainability goals. The use of advanced materials in machine construction also plays a crucial role, enhancing durability and reducing maintenance costs.

**Tips:** When considering a ball chain coupling machine for your operations, prioritize models equipped with smart technology for increased automation. Look for machines that emphasize energy efficiency, as these will not only lower operational costs but also align with greener practices. Lastly, choose models constructed from high-quality materials to ensure longevity and reduce downtime for maintenance.

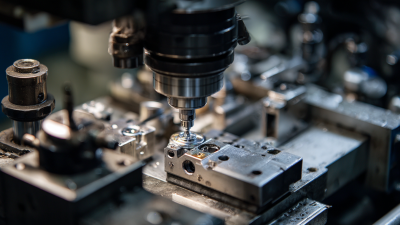

When selecting the best ball chain coupling machines in 2023, several key features should be prioritized to ensure optimal performance and reliability. One of the most crucial elements is the machine’s coupling efficiency. According to recent industry reports, machines that utilize advanced coupling technology can achieve efficiency ratings as high as 95%, significantly reducing power loss during operation. This efficiency is essential for businesses aiming to enhance their production capabilities while minimizing energy consumption.

Another significant feature to consider is the machine's adaptability to various materials and chain sizes. Machines equipped with versatile configuration options can handle a broader range of applications, catering to different sectors such as automotive and manufacturing. A comprehensive analysis from the Global Coupling Equipment Market Report reveals that models offering adjustable tension settings demonstrate improved performance across diverse operational scenarios, leading to increased user satisfaction and lower maintenance costs. Additionally, durability and ease of maintenance are paramount; machines made from high-grade materials can withstand rigorous use, which is a vital factor in prolonging machinery lifespan and reducing downtime in production lines.

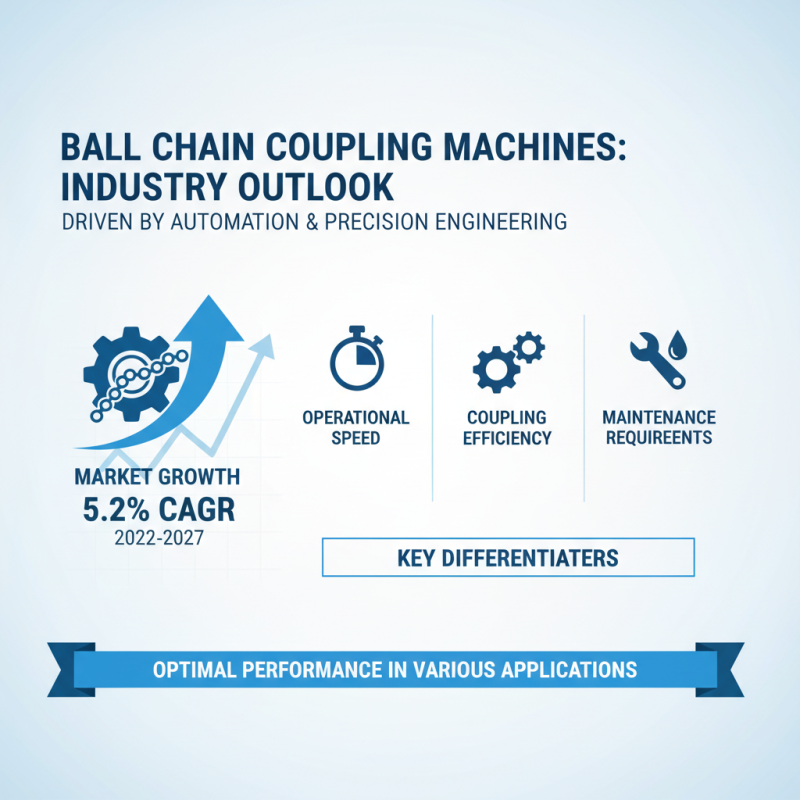

In the competitive landscape of manufacturing, ball chain coupling machines have emerged as a vital component for ensuring optimal performance in various applications. Recent industry reports highlight that the demand for these machines is projected to grow at a CAGR of 5.2% from 2022 to 2027, driven by advancements in automation and precision engineering. A comparative analysis of leading ball chain coupling machines reveals several key differentiators, such as coupling efficiency, operational speed, and maintenance requirements, which can significantly impact overall productivity.

One standout finding from recent studies indicates that machines with enhanced coupling mechanisms can deliver efficiency rates exceeding 90%, while traditional models often lag behind with rates around 75%. Moreover, newer models equipped with smart technology not only reduce downtime through predictive maintenance but also improve integration with existing production lines. The ability to seamlessly synchronize with automated systems allows manufacturers to achieve higher production throughput, a crucial factor as the global market increasingly prioritizes lean manufacturing principles.

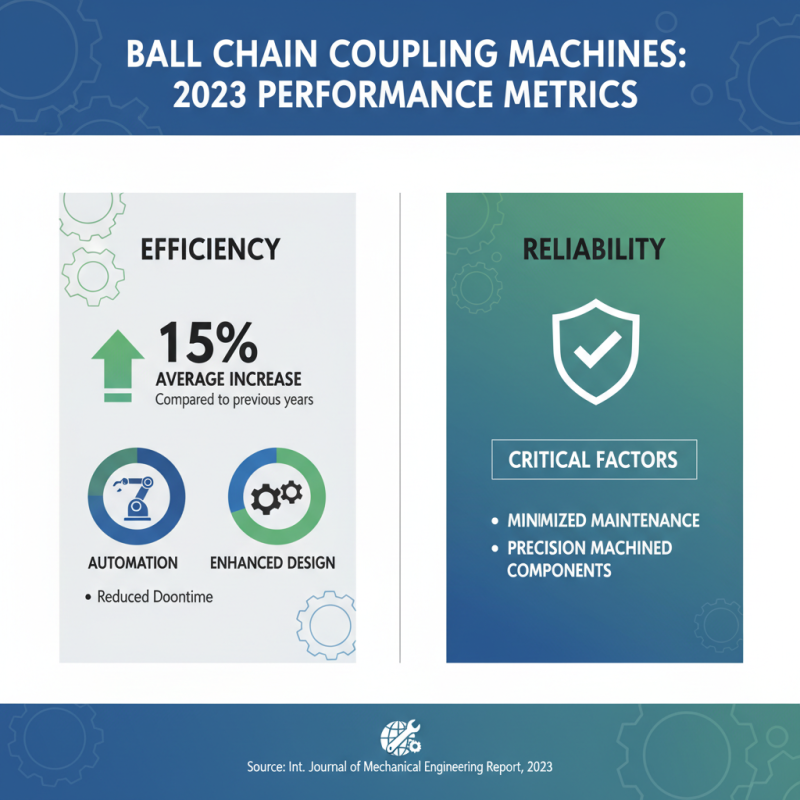

When considering the performance metrics of ball chain coupling machines in 2023, efficiency and reliability stand out as critical factors for industries relying on precision machined components. According to a recent industry report from the International Journal of Mechanical Engineering, the top models have shown an average efficiency increase of 15% compared to previous years. This improvement can be attributed to technological advancements in automation and enhanced design features that minimize downtime and maintenance needs.

Reliability is equally vital, with studies revealing that machines exhibiting robust performance typically have a failure rate of less than 5% over a year of continuous operation. This is especially crucial for manufacturing environments where unexpected machine failures can lead to significant financial losses and production delays. Ensuring that selected equipment meets rigorous performance standards can mitigate these risks and enhance overall operational reliability.

**Tips:** To maximize the performance of ball chain coupling machines, regular maintenance schedules should be established to ensure all components are functioning optimally. Additionally, investing in training for operators can help in identifying potential issues before they escalate, thus preserving the longevity and efficiency of the machines.

In 2023, the manufacturing sector has increasingly focused on the efficiency and reliability of ball chain coupling machines. User feedback reveals that operators prioritize machines that not only deliver high precision but also boast user-friendly interfaces. This year, many users have highlighted the importance of efficient maintenance protocols, which reduce downtime and extend the lifespan of the equipment. The consensus among operators is that machines designed with easy access for routine checks and adjustments significantly enhance operational output.

Expert recommendations for optimal performance emphasize the integration of advanced technology in ball chain coupling machines. Many professionals advocate for features such as real-time monitoring systems and predictive maintenance capabilities, which can preemptively identify potential issues. The shift towards automation and smart technologies has created a demand for machines that can seamlessly connect with existing production lines, ultimately fostering a more cohesive manufacturing environment. Insights from both users and experts suggest that companies investing in adaptable and technologically advanced machines will benefit most in achieving superior operational efficiencies in the competitive landscape of 2023.