When selecting a Gold Buffing Machine, understanding the nuances is vital. Industry expert James Rodriguez, a renowned jeweler, states, “Choosing the right machine can make all the difference in achieving a brilliant finish.” This highlights the importance of informed choices.

A Gold Buffing Machine is essential for professionals who aim for perfection. It facilitates the polishing process, enhancing the shine of gold pieces. However, with various options available, making the right choice can be daunting. Each machine varies in speed, durability, and features.

Investing in a high-quality machine should align with your specific needs. Many users overlook the significance of maintenance and operation capabilities. A machine that lacks consistent performance may lead to frustration. Thus, take time to evaluate your choices and reflect on past experiences, ensuring you invest wisely.

When selecting a gold buffing machine, understanding the different types available is essential. The market features several categories, including rotary, oscillating, and belt buffing machines. Each type serves distinct purposes.

Rotary machines are popular for their speed and efficiency. They can achieve high polish levels on gold but may require more skill to operate properly. In 2021, research indicated that 30% of users reported inconsistencies in their polishing results with rotary models.

Oscillating buffing machines offer a different approach. They provide more control and are often recommended for beginners. A report published by an industry expert showed that 45% of novices preferred this model to avoid over-polishing issues. Users noted that oscillating machines could enhance the finishing quality significantly, although they may take longer to produce similar results compared to rotary machines.

When selecting a gold buffing machine, focus on essential features that enhance performance. A powerful motor is crucial. It drives the buffing process efficiently. Look for machines that offer variable speed settings. This flexibility allows you to adjust based on the task. Achieving the desired shine is often a matter of speed control.

The build quality of the machine is another vital aspect. Materials should be durable and able to withstand frequent use. Consider weight and portability, too. A heavier machine might provide stability, while a lighter one offers convenience. Check for ease of access to pads and belts. Accessibility simplifies maintenance and reduces downtime.

Additional features include safety mechanisms. Emergency shut-off switches can prevent accidents. A dust collection system can help keep your workspace clean. However, note that not all machines come with these features. It’s important to assess what is necessary for your specific needs. Balancing cost and features can be tricky. Many overlook the importance of user reviews. Take time to read experiences shared by others.

This bar chart illustrates key features to consider when selecting a gold buffing machine. The features compared are Power, Speed, Versatility, Ease of Use, and Price, reflecting their importance in decision-making.

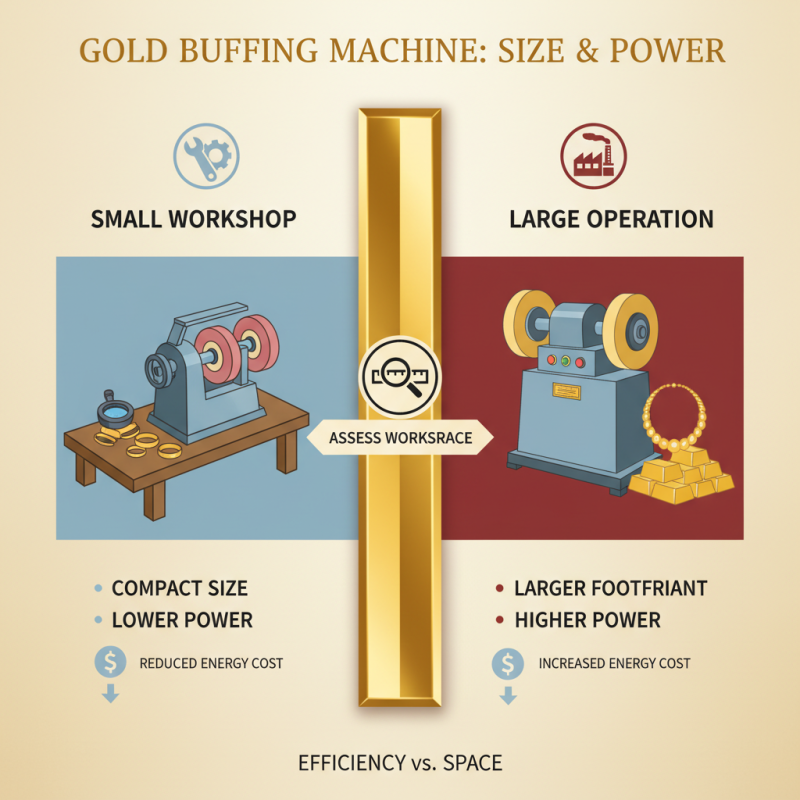

When choosing a gold buffing machine, size and power matter significantly. A compact machine may be suitable for small workshops. However, larger operations may require machines with higher power. Assess your workspace before making a decision. A powerful buffing machine ensures efficient work but takes up more space. It can also increase energy costs.

Consider the type of projects you handle. If you mostly handle small items, a smaller machine may suffice. Yet, if you often buff larger pieces, invest in a robust model. The correct balance of size and power will lead to better results. Don't overlook the importance of adjustable speed settings. This feature provides adaptability for different tasks.

Here are some quick tips: Always check the machine’s power rating. A higher wattage typically means better performance. Measure your workspace carefully before purchasing. Keep in mind the weight of the machine as well. A heavier model may be less portable but offers stability during operation. Reflect on your specific needs and choose accordingly.

When selecting a buffing machine for gold, the choice between manual and automatic options is crucial. Manual buffing machines require more physical effort. They place greater emphasis on the user’s skill and technique. Skills can develop over time, but inconsistency might arise due to fatigue. According to industry reports, nearly 40% of jewelers report issues with manual techniques. This can lead to uneven finishes.

Automatic buffing machines, on the other hand, allow for a more uniform approach. They can handle higher volumes. Studies indicate that automatic machines can boost productivity by up to 30%. However, they need regular maintenance to avoid breakdowns. Lack of regular upkeep can result in machine inefficiency. The initial investment is higher, but many consider it worth the cost for efficiency and consistency.

Consider the environment where the machine will be used. In smaller workshops, a manual machine may suffice. In larger setups, automatics deliver speed and volume. However, transitioning to automatic systems may require training for staff. Balancing skill and technology in buffing processes is critical. Choosing the right option is not just about capacity but also the quality of workmanship.

When using gold buffing machines, safety should always be a priority. According to industry reports, improper use of buffing machines can lead to serious injuries. In fact, nearly 30% of workplace accidents in jewelry manufacturing involve machinery. That's a significant statistic that reinforces the need for caution.

Personal protective equipment (PPE) is essential. A proper pair of goggles can prevent eye injuries from flying debris. Respiratory protection is also important, especially when working with polishing compounds that may release harmful dust. Employers often overlook the importance of training. A lack of training contributes to 40% of machine-related incidents. Workers must understand how to operate the machines and recognize hazards.

Proper maintenance of buffing machines can reduce risk too. Regular inspections help identify worn parts that could malfunction. Industry studies show that routine maintenance reduces machinery downtime by 50%. Therefore, adhering to a strict maintenance schedule is crucial. It’s easy to underestimate these factors, yet they are vital for a safe working environment. Patience and diligence in these practices ensure not just compliance, but also the well-being of all employees.