In today's fast-paced industrial landscape, optimizing operations has become more critical than ever, and one essential tool for achieving this efficiency is the Cable Chain Coupling Machine. These machines serve a vital role in connecting different components of a production line, ensuring seamless energy transfer and reducing downtime. By employing advanced engineering principles, Cable Chain Coupling Machines not only enhance the reliability of operations but also improve overall productivity. In this guide, we will explore various strategies and best practices for optimizing the use of Cable Chain Coupling Machines, enabling businesses to streamline their workflows, minimize errors, and boost operational efficiency. Whether you are looking to upgrade existing systems or implement new solutions, understanding how to leverage these machines effectively can significantly impact your bottom line and long-term success.

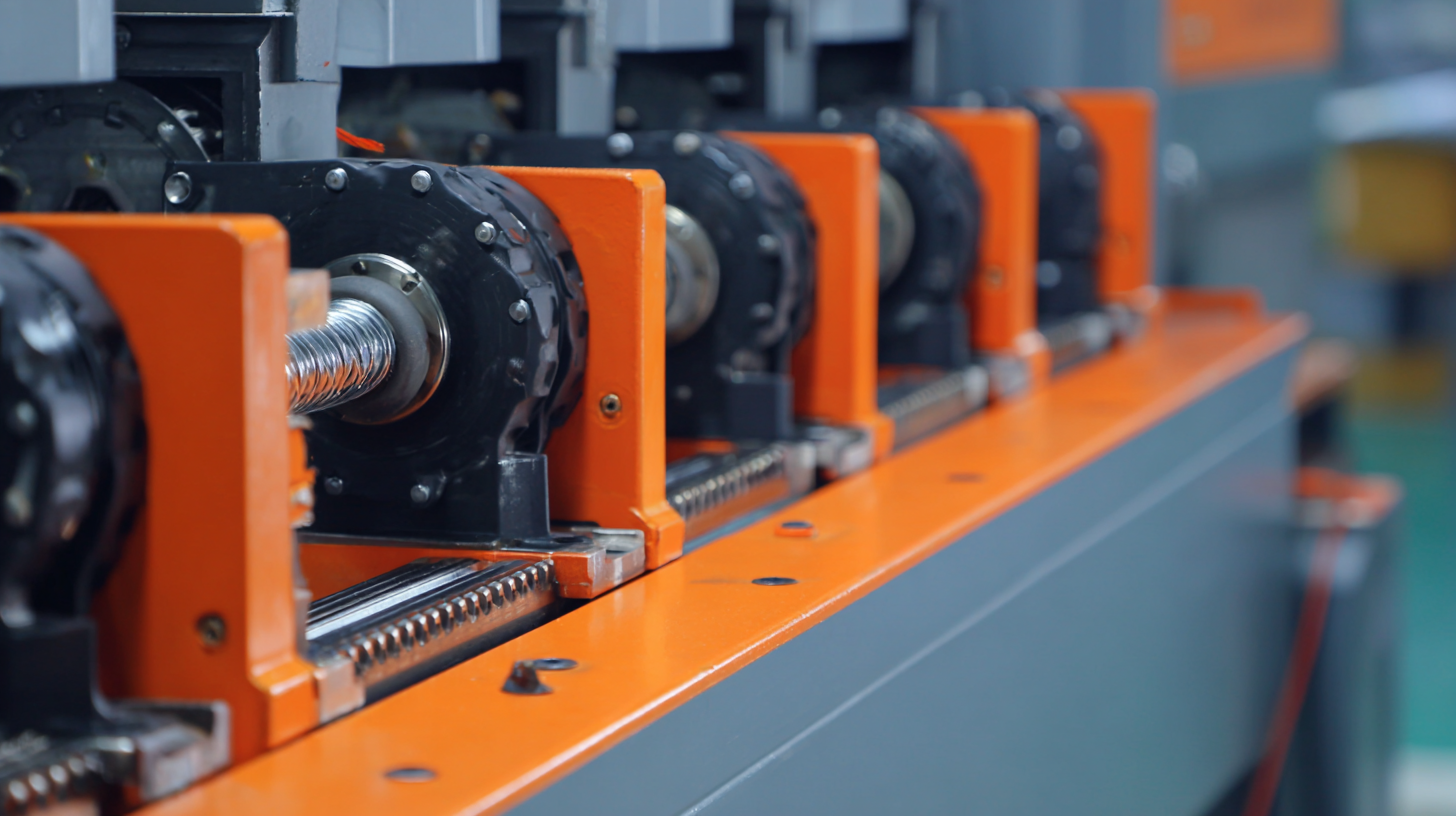

Cable chain coupling machines play a crucial role in various industrial applications, particularly in the field of automation and conveyor systems. These machines comprise essential components, including cable chains, drive mechanisms, and coupling systems. According to a recent report by Research and Markets, the global market for cable chains is projected to grow at a CAGR of 5.3% between 2022 and 2027, reflecting a heightened demand for efficient material handling solutions.

The functionality of cable chain coupling machines lies in their ability to provide smooth and reliable operation in transporting materials across different stages of production. The cable chain, often made from high-strength plastics or metals, ensures durability and resistance to wear and tear. This is especially important in environments where heavy loads are common, as noted in a study by the International Society of Automation, which indicated that improper coupling can lead to downtime costs averaging $250,000 per incident. By optimizing the key components and properly maintaining the cable chain systems, industries can significantly reduce operational inefficiencies and enhance productivity.

| Component | Functionality | Material | Applications |

|---|---|---|---|

| Cable Chain | Guides and protects cables | Plastic / Steel | Industrial machinery |

| Coupling Mechanism | Connects moving parts | Metal Alloy | Robotics |

| Mounting Bracket | Secures the system to the machine | Aluminum | Automotive |

| Guide Plates | Directs movement of the cable chain | Plastic | Manufacturing |

| Slack Take-Up | Adjusts the tension in cables | Spring Steel | Cranes |

The process of cable chain coupling is critical in various industries such as automotive, aerospace, and manufacturing. However, it often faces significant operational challenges that can hinder efficiency. According to the "2023 Global Robotics and Automation Market Report," nearly 38% of companies experience increased downtime due to inadequate coupling mechanisms. This not only affects production rates but also amplifies maintenance costs. Operational bottlenecks primarily arise from misalignment, insufficient tensioning, and wear and tear on cable components, leading to frequent breakdowns.

Moreover, a survey conducted by the International Society of Automation in 2022 revealed that 45% of facilities identified poor cable management practices as a significant barrier to operational success. Inefficient cable chain configurations can impede system performance, resulting in energy losses that can reach up to 20%. Investing in optimized cable chain coupling machines that feature advanced monitoring technology can mitigate these challenges. By employing predictive maintenance systems, companies can preempt mechanical failures, thus enhancing uptime and operational productivity while reducing overall expenses.

To enhance efficiency in cable chain coupling operations, implementing a systematic approach is crucial. One effective strategy is to conduct a thorough analysis of the current operational workflow. Identifying bottlenecks and areas of redundancy can help management streamline processes, thereby reducing production time. Utilizing data analytics tools can provide valuable insights into machine performance and operational speed, allowing teams to make informed adjustments that enhance overall productivity.

Another key strategy involves investing in employee training and development. Ensuring that operators are well-versed in the latest techniques and technologies associated with cable chain couplings can drastically improve operational efficiency. Regular workshops and hands-on training sessions can empower employees to troubleshoot issues more effectively and adopt best practices in their daily tasks. Furthermore, fostering an environment that encourages continuous improvement and innovation can lead to the discovery of new methods to optimize processes and reduce downtime.

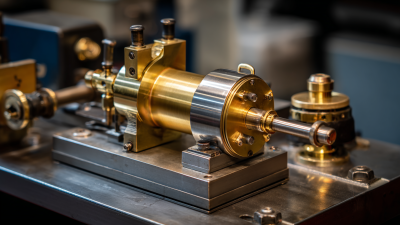

In the realm of machinery, the importance of implementing robust maintenance protocols cannot be overstated, particularly when it comes to cable chain coupling machines. Regular maintenance not only extends the life of the equipment but also enhances its operational efficiency. According to a recent industry report, proactive maintenance can reduce equipment downtime by up to 30%, which translates into significant cost savings for businesses. Observing proper maintenance schedules allows for timely detection of wear and tear, ensuring that the cable chains operate at peak performance.

In addition to regular inspections, lubrication and adjustments are critical to maintaining optimal cable chain performance. A study highlighted that machines with well-lubricated cable chains exhibit 15-20% lower energy consumption compared to those that are neglected. Moreover, with advancements in technological monitoring systems, companies can harness data analytics to predict maintenance needs, thereby preventing unexpected failures. This strategic approach not only maximizes productivity but also enhances safety, minimizing the risk of operational hazards associated with worn-out machinery.

In today’s fast-paced manufacturing environment, utilizing technology is essential for optimizing workflows in cable chain coupling machines. By implementing advanced automation tools and software systems, businesses can significantly reduce operational downtime. These technologies not only enhance precision in coupling processes but also streamline communication between different machine parts, ensuring a smoother operation overall.

**Tips:** One effective strategy is to integrate real-time monitoring systems that provide instant feedback on the operational status of machines. This allows technicians to swiftly address potential issues before they escalate, maintaining workflow continuity. Additionally, investing in predictive maintenance technology can help foresee equipment failures, thus optimizing maintenance schedules and minimizing unexpected halts.

Furthermore, utilizing data analytics can reveal trends in machine performance, enabling better decision-making regarding resource allocation and process improvements. By analyzing production data, manufacturers can identify bottlenecks in their workflows and implement targeted solutions to enhance efficiency. With these technological advancements, the cable chain coupling industry can achieve higher productivity and better overall outcomes.