As the global manufacturing landscape continues to evolve, the significance of optimizing production machinery has gained unprecedented attention, particularly for the jewelry and accessory sectors. In 2025, manufacturers are increasingly focusing on enhancing the efficiency of their operations to stay competitive. Among the critical assets in this process is the Franco Chain Making Machine, vital for producing intricate and durable chain jewelry. Recent industry reports indicate that manufacturers who implement advanced operational techniques can improve production efficiency by up to 30%, directly influencing profit margins.

Incorporating automation and precision engineering into the production process allows manufacturers to maximize output while maintaining quality standards. The Franco Chain Making Machine, when optimized, not only accelerates the chain-making process but also reduces material wastage and energy consumption. According to a report by Market Research Future, the demand for chain-making machinery is projected to grow by 15% annually, highlighting the necessity for companies to adopt best practices in machine operation to meet market needs effectively. By focusing on the optimization of the Franco Chain Making Machine, manufacturers can lead the charge in innovation and sustainability within their operations, paving the way for a more efficient and environmentally-conscious future.

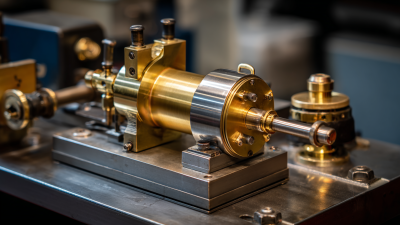

To enhance the efficiency of a Franco chain making machine, it is essential to understand its key components. The machine typically includes critical elements such as the chain feeding system, welding unit, and cutting mechanism. Each component plays a pivotal role in ensuring smooth operation and high production rates. For instance, optimizing the welding unit can significantly reduce cycle times and improve the quality of the finished product, leading to higher throughput.

**Tips:** Regular maintenance and calibration of these components can prevent machine downtime and costly production halts. Additionally, implementing machine learning algorithms can help in analyzing operational data, identifying inefficiencies, and predicting maintenance needs, contributing to overall productivity.

As the global corrugated box making machine market is set to grow from $0.95 billion in 2025 to $1.36 billion by 2032 at a CAGR of 5.2%, efficiency in production processes like those used with Franco chain making machines becomes increasingly critical. By focusing on the integration of advanced technologies and optimizing existing machinery, manufacturers can stay competitive in a rapidly evolving market.

When optimizing a Franco chain making machine, identifying common bottlenecks in production processes is crucial for maximizing efficiency. One of the first steps is conducting a thorough analysis of the workflow. By mapping out each stage of the production process, manufacturers can pinpoint where delays commonly occur. For instance, excessive inventory or inefficient machine settings can lead to slowdowns, affecting overall productivity.

Once these bottlenecks are identified, solutions can be tailored to address the specific issues. Implementing automation in certain stages can significantly reduce manual handling and speed up production. Additionally, regular maintenance of machinery ensures that equipment operates at peak performance, minimizing downtime. Embracing lean software development principles can also be beneficial, as they encourage continuous improvement and waste reduction, ultimately streamlining processes.

By focusing on these aspects, manufacturers can enhance their production efficiency and remain competitive in 2025.

In the competitive vertical of chain manufacturing, optimizing your Franco chain making machine is pivotal for maximizing productivity and efficiency. Implementing technological upgrades can significantly enhance machine performance, ensuring that operations run seamlessly. According to a report by the Manufacturing Technology Association, companies that invest in advanced machinery and automation systems can see productivity increases of up to 30%. Such upgrades not only streamline processes but also reduce downtime caused by machine inefficiencies.

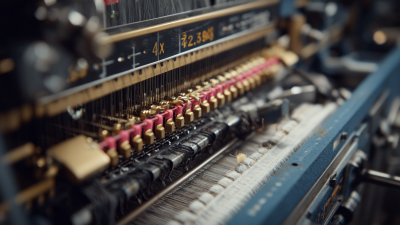

Tips for enhancing your machine's performance include regularly updating the software systems and incorporating IoT sensors for real-time monitoring. These systems can provide crucial data, such as machine temperature and operating speeds, which help in predicting maintenance needs and preventing unexpected failures. Additionally, integrating advanced materials into your chains can lead to a reduction in wear and tear, extending the machine's lifespan and further optimizing production cycles.

Moreover, investing in training programs for your operators is essential. Research from the International Journal of Production Research indicates that well-trained employees can improve machine output by 15-20% through better operational practices. Empowering your workforce with the right skills and knowledge is a strategic step in ensuring that your Franco chain making machine operates at its full potential.

Training personnel on best practices is essential for optimizing the operation of a Franco chain making machine. In a high-efficiency production environment, workers must be well-versed in the specific functionalities of the machinery. Training programs should encompass not only the operational aspects but also the maintenance protocols that minimize downtime. By ensuring that personnel are adept at recognizing early signs of wear or malfunction, organizations can significantly reduce operational interruptions and enhance overall productivity.

Additionally, ongoing training and development are vital as technology evolves. Incorporating advanced simulation tools in training can provide workers with hands-on experience in a controlled setting, facilitating a deeper understanding of machine intricacies without the risk of real-world errors. By fostering a culture of continuous learning, companies can empower their workforce to implement innovative strategies that drive efficiency and machine longevity. This proactive approach to personnel training ultimately leads to a more resilient production environment and contributes significantly to achieving maximum efficiency in operations.

| Parameter | Value | Units | Optimal Range |

|---|---|---|---|

| Chain Speed | 25 | m/min | 20-30 |

| Temperature | 150 | °C | 140-160 |

| Pressure | 3.5 | bar | 3-4 |

| Maintenance Frequency | Monthly | N/A | Every 1-2 months |

| Operator Training Duration | 5 | days | 4-6 |

Regular maintenance is essential for sustaining the high efficiency of your Franco chain-making machine. Implementing a routine maintenance schedule can significantly reduce downtime and ensure that the machine operates at its optimal parameters. Key tasks should include regular cleaning to remove dust and debris that can accumulate, leading to possible malfunctions. Additionally, checking and tightening bolts and screws is crucial to maintain the structural integrity of the machine. Lubricating moving parts on a scheduled basis will also prevent excessive wear and extend the lifespan of critical components.

Another important strategy is to conduct periodic inspections of electrical systems and software updates. Keeping software up to date can streamline operations and enhance performance. Regularly monitoring machine performance metrics allows operators to identify any deviations from normal functioning and address them promptly. Training staff on proper usage and maintenance techniques is equally important, as it fosters a culture of care and responsibility that contributes to the longevity and efficiency of the machine. Through diligent maintenance practices, the Franco chain-making machine can achieve sustained efficiency and productivity over time.