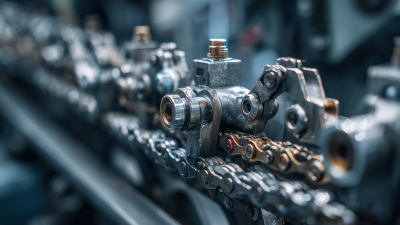

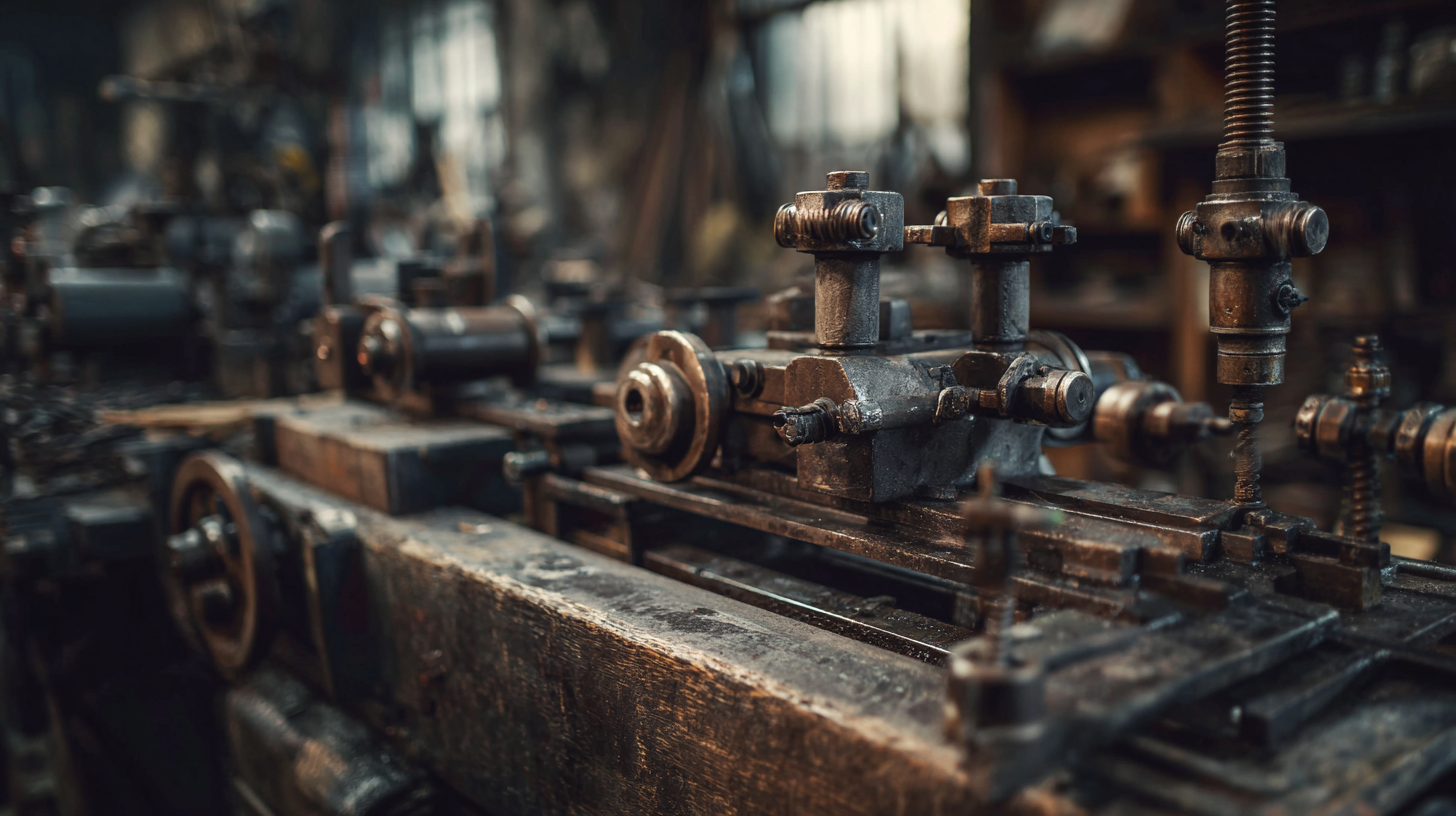

In the ever-evolving landscape of manufacturing, the revival of old chain making machines is proving to be a crucial factor in retracing our steps towards a more sustainable and efficient industry. Experts in the field recognize the importance of these antique machines, not just for their nostalgic value, but for their unique capabilities that modern technology often overlooks. John Thompson, a renowned authority in chain manufacturing, emphasizes this point by stating, “Old chain making machines possess a distinctive craftsmanship that modern counterparts simply cannot replicate.”

As we delve into the reasons behind the revival of these traditional machines, it's essential to understand their role in preserving techniques that have been honed over decades. They serve as a bridge between past practices and current needs, embodying the artistry and meticulous care that define quality manufacturing. In an age where automation tends to overshadow intricate craftsmanship, old chain making machines remind us of the value of skilled labor and attention to detail.

The discussion of integrating old chain making machines into contemporary manufacturing processes invites us to rethink innovation. It encourages a balanced approach where tradition meets modern demands, paving the way for a resurgence in industries that prioritize not only speed and efficiency but also heritage and expertise. As the manufacturing sector looks to the future, the revival of these machines may well hold the key to a more robust and resilient industry.

The historical significance of old chain making machines lies in their pivotal role in the evolution of the manufacturing industry. These machines, which date back to the early days of industrialization, exemplify the ingenuity and craftsmanship that characterized a bygone era. They played a fundamental part in streamlining production processes, allowing for the mass creation of chains that were essential for various applications, from machinery to transportation. By understanding and appreciating these machines, we gain insight into the foundational techniques that shaped modern manufacturing.

Furthermore, reviving the use of old chain making machines can ignite a renaissance in the manufacturing sector. As industries face the challenges of automation and rapid technological advancements, returning to traditional methods can offer valuable lessons in durability, sustainability, and craftsmanship. The revival not only preserves historical manufacturing techniques but also fosters innovation by blending time-honored practices with contemporary designs. This fusion could lead to a resurgence in small-scale manufacturing, honoring the past while paving the way for a more resilient future.

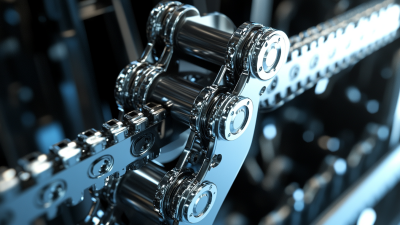

The revival of the manufacturing industry is significantly aided by the use of vintage production equipment, particularly old chain making machines. These machines are not only a testament to mechanical endurance but also offer unique benefits that modern equipment often cannot match. According to a recent report by IndustryWeek, companies using vintage machinery can experience up to a 30% increase in production efficiency due to the simplicity and durability of these older models. Furthermore, the lower initial investment costs associated with vintage equipment make it accessible for smaller manufacturers looking to expand their operations without substantial financial risk.

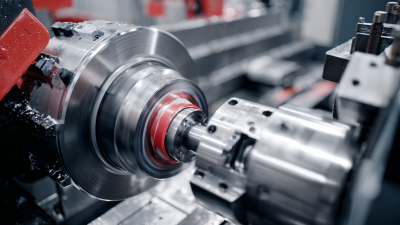

When considering the integration of vintage machines, keep in mind that they often require less energy to operate compared to their modern counterparts, resulting in substantial long-term savings. Regular maintenance and refurbishment can ensure that these machines run optimally for decades.

Tips for maximizing the use of vintage equipment include conducting thorough assessments of each machine's condition before purchasing and investing in skilled technicians who understand the nuances of older technology. This proactive approach not only preserves the investment but also guarantees that the unique capabilities of vintage machines are fully utilized in the manufacturing process.

The resurgence of old chain making machines in today’s manufacturing landscape highlights a fascinating paradox: how antiquated technology can surprisingly enhance modern efficiency. According to a recent report from the International Manufacturing Technology Show, manufacturers that integrate vintage machinery into their operations have recorded up to a 30% increase in production speed. This remarkable statistic stems from the durability and simplicity of these machines, which often require less maintenance and downtime compared to newer models equipped with complex electronics.

Furthermore, the revival of older machines can significantly reduce operating costs. The Manufacturing Institute found that companies utilizing aged equipment typically see a 25% reduction in energy consumption. The straightforward mechanics of these machines often translate to fewer points of failure, leading to less energy wasted during operation. As manufacturers seek to balance the demands of sustainable production with economic viability, the charm of old chain making machines becomes clear: not only do they bring reliability, but they also foster an environment that encourages efficiency and resourcefulness in the face of modern economic challenges.

| Machine Type | Year Manufactured | Efficiency Rating (%) | Maintenance Requirement | Cost Savings ($) |

|---|---|---|---|---|

| Hydraulic Chain Press | 1995 | 85 | Low | 5000 |

| Manual Chain Linker | 1980 | 75 | Medium | 3000 |

| CNC Chain Cutter | 2005 | 90 | High | 7000 |

| Chain Assembly Line | 1990 | 80 | Low | 4500 |

| Electric Chain Riveter | 2000 | 88 | Medium | 6000 |

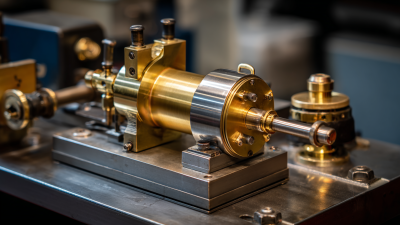

Integrating traditional manufacturing practices with modern technology can unlock significant potential in the manufacturing industry. Old chain-making machines, often overlooked, offer a unique blend of durability and craftsmanship that can enhance production quality. By refurbishing these machines and incorporating them into contemporary manufacturing lines, companies can maintain the rich heritage of craftsmanship while benefiting from the precision of modern innovation. This juxtaposition of old and new provides a competitive edge, attracting consumers who value sustainability and authenticity.

To effectively utilize old machines, manufacturers should prioritize training their workforce on the intricacies of these machines. Knowledge transfer from seasoned operators to younger employees ensures that traditional skills are preserved and enhanced with modern techniques. Additionally, developing a hybrid production workflow that allows for the seamless integration of old machines with new technologies can optimize efficiency. By adopting best practices such as regular maintenance, obtaining high-quality components for upgrades, and fostering an environment of continuous improvement, businesses can not only revive these machines but also contribute to a sustainable and innovative manufacturing ecosystem.

In recent years, a resurgence of interest in traditional manufacturing techniques has emerged, highlighting the role of old chain making machines in revitalizing the industry. Case studies from various regions illustrate how embracing classic methodologies can yield impressive outcomes. For instance, a small workshop in Italy that integrated vintage chain-making equipment reported a 30% increase in productivity. By combining the charm of handcrafted processes with modern design aesthetics, the workshop successfully attracted a niche market of consumers seeking unique, artisanal products.

Another compelling example comes from a factory in the United States, which restored old chain making machines to meet the demand for locally sourced materials. By leveraging these machines, the factory not only reduced production costs but also diminished its carbon footprint, appealing to environmentally conscious consumers. The revival of these classic techniques fostered a deeper connection between the product and its origins, allowing the factory to carve out a distinct identity in a crowded marketplace. These case studies exemplify that the wisdom of the past can play a vital role in shaping the future of manufacturing.