In the rapidly evolving landscape of manufacturing, efficiency has become a critical metric for success, especially in industries relying on advanced machinery. The Box Chain Coupling Machine stands at the forefront of this drive for enhanced productivity, offering seamless power transmission and minimal downtime. According to a recent industry report by MarketsandMarkets, the global coupling market is projected to reach USD 10.3 billion by 2024, with a significant portion attributed to innovations in coupling technologies such as the Box Chain Coupling Machine. This machine not only improves operational efficiency but also reduces energy consumption, promoting a sustainable future in manufacturing.

As companies seek to enhance their production capabilities, investing in high-quality Box Chain Coupling Machines represents a strategic move towards achieving excellence in manufacturing practices—a commitment that resonates with the guiding principle of "卓越制造,源自中国,服务全球."

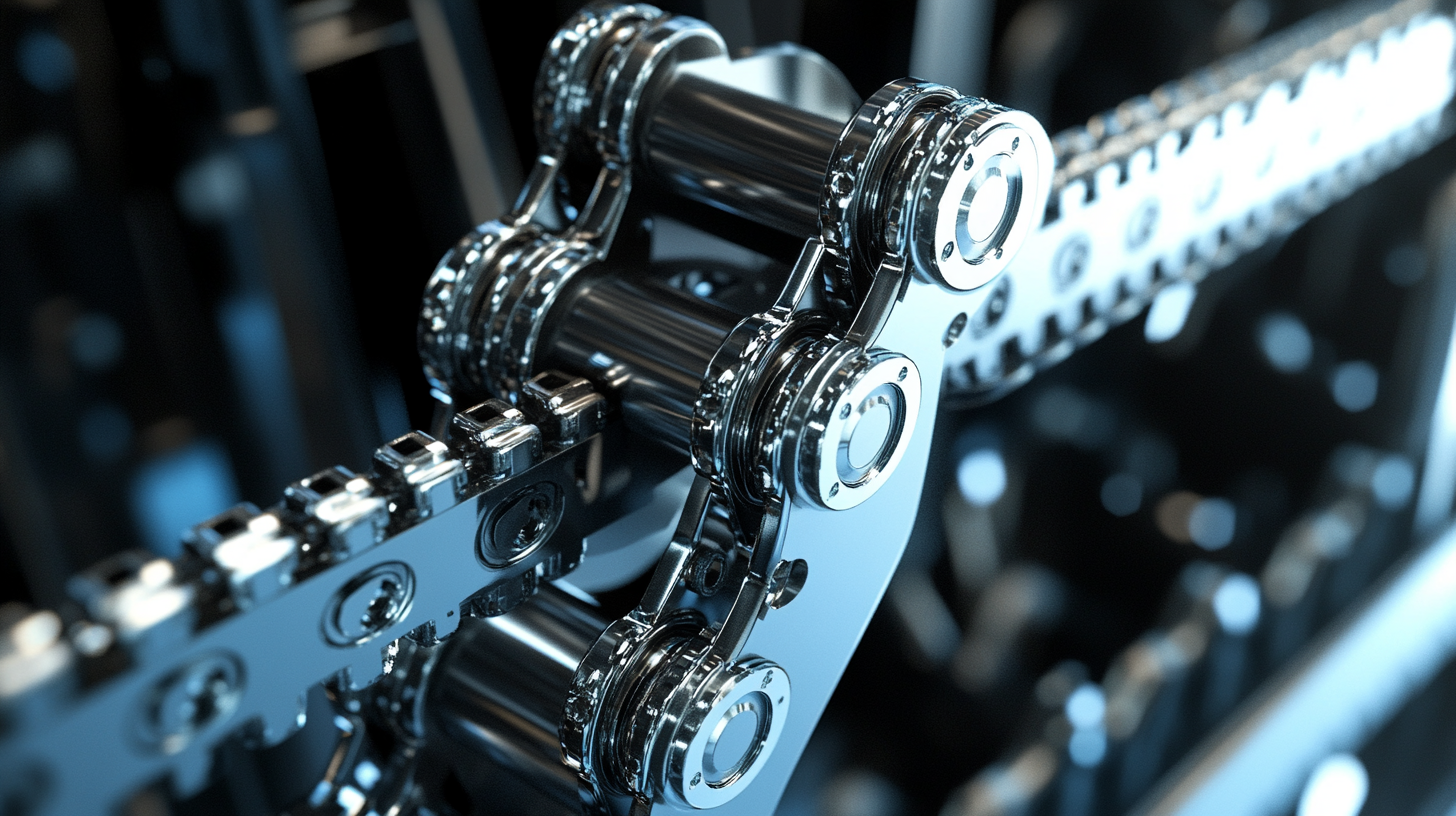

Box chain couplings play a crucial role in enhancing the efficiency of various mechanical operations. Understanding the key features and benefits of these couplings is essential for optimizing performance in industries ranging from manufacturing to robotics. Box chain couplings facilitate smooth torque transfer between machine components, resulting in reduced wear and increased longevity of the equipment.

Tip: When selecting a box chain coupling machine, consider factors such as load capacity, speed ratings, and maintenance requirements. These considerations will ensure that your coupling system operates efficiently and meets your operational demands.

Another advantage of box chain couplings is their ability to withstand misalignment between shafts. This is particularly beneficial in dynamic environments where equipment may experience vibrations and shifts. By providing flexibility, these couplings contribute to minimizing downtime, offering significant cost savings in the long run.

Tip: Regularly inspect and maintain your box chain couplings to identify any signs of wear or fatigue. Timely maintenance can prevent larger issues, ensuring continuous operation and efficiency.

The box chain coupling machine stands at the forefront of current industrial trends, offering innovative solutions for enhancing operational efficiency. As industries increasingly shift towards automation and precision, the demand for advanced coupling mechanisms has surged. The recent data indicating the growth of Ghana's shaft coupling market underscores this shift, reflecting a substantial increase in revenue that highlights the potential for similar advancements in other regions. This surge can be attributed to the growing necessity for reliable machinery that ensures seamless connectivity within complex systems.

To maximize efficiency, manufacturers are focusing on the integration of smarter technologies within box chain coupling machines. These trends include implementing real-time monitoring systems and advanced materials that offer greater durability and performance. As companies strive to reduce downtime and maintenance costs, the emphasis on coupling machines that provide both flexibility and robustness is becoming critical. Understanding these industry shifts is essential for any business looking to stay competitive and leverage the latest advancements in coupling technology.

Quality assurance is a critical component in the manufacturing process, particularly within the Chinese manufacturing sector, which has been a global leader in production capabilities. According to a report by McKinsey & Company, Chinese manufacturers have improved their quality control processes significantly, with 64% of firms implementing advanced quality management systems. This shift not only enhances the reliability of products such as box chain coupling machines but also strengthens customer trust in Chinese-made goods.

Moreover, the implementation of real-time monitoring technologies has led to a 25% reduction in defects in manufacturing lines, as highlighted in a study by PwC. Manufacturers are now capable of utilizing data analytics to identify inefficiencies and potential quality issues before they escalate, thus maximizing overall performance. This proactive approach is particularly beneficial for industries requiring precision machinery, where even minor defects can lead to substantial operational setbacks. Through rigorous quality assurance processes, Chinese manufacturers are ensuring that their products not only meet international standards but also compete effectively on the global stage.

Maximizing productivity in modern manufacturing requires the effective use of machinery, and box chain coupling machines play a crucial role in ensuring operational efficiency.

A recent report by the International Association of Engineered Products noted that incorporating advanced coupling solutions can increase production line efficiency by up to 15%. This improvement is primarily attributed to reduced downtime and the capability of these machines to handle higher torque loads without compromising accuracy.

To fully maximize the potential of box chain coupling machines, best practices must be implemented. Regular maintenance, for instance, ensures that the machinery operates at optimal levels. According to a study conducted by the Machinery Maintenance Institute, routine checks can prevent 70% of unexpected failures. Additionally, training operators on the specific features and operational parameters of these machines can lead to a 20% increase in overall productivity. By focusing on these best practices, companies can harness the full capabilities of box chain coupling machines and drive significant improvements in their manufacturing processes.

In the rapidly evolving landscape of manufacturing, leading global brands are increasingly turning to box chain couplings to enhance their operational efficiency. A recent report from Industry Research suggests that companies utilizing advanced coupling solutions have seen a reduction in downtime by nearly 25%. These couplings not only improve power transfer but also minimize wear and tear on machinery, enhancing overall productivity. For instance, a prominent automotive manufacturer reported a 15% increase in assembly line speed after integrating box chain couplings into their systems.

One insightful case study from the food processing industry reveals that a major brand successfully shortened its production cycle by 20%following the implementation of box chain couplings. This success was largely attributed to the couplings' ability to withstand high loads and maintain precision alignment under various operational conditions. Such enhancements in durability and efficiency demonstrate the value of adopting cutting-edge coupling technology.

**Tip:** When considering box chain couplings, evaluate the compatibility with existing equipment. Proper alignment and load rating are critical for maximizing performance.

**Tip:** Regular maintenance and inspection of couplings can further enhance lifespan and efficiency, potentially saving companies significant costs in the long run. Consistent evaluation of coupling wear can prevent unscheduled downtime and production delays.

This chart illustrates the percentage improvement in efficiency attributed to the use of box chain couplings over the past five years. It highlights a significant trend in enhancing operational performance across various industries.