The efficiency of industrial machinery is critical to maintaining competitive advantage in today's fast-paced manufacturing environment. According to a recent report by the International Machine Tool Survey, companies implementing optimized coupling systems, such as the Bismark Chain Coupling Machine, have reported a 20% increase in operational efficiency and a 15% reduction in downtime. These statistics underscore the importance of adopting best practices in the maintenance and operation of these sophisticated machines. In this blog, we will explore seven essential tips for maximizing efficiency with the Bismark Chain Coupling Machine, drawing insights from industry experts and case studies to enhance productivity and streamline processes in your operations. By integrating these strategies, organizations can not only optimize their use of this cutting-edge technology but also align with industry standards for performance and reliability.

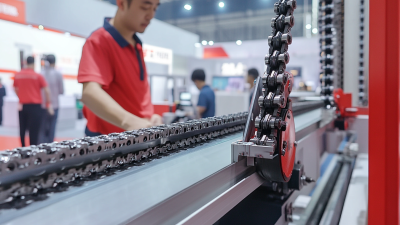

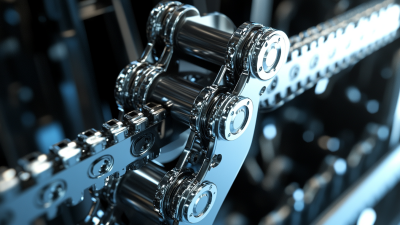

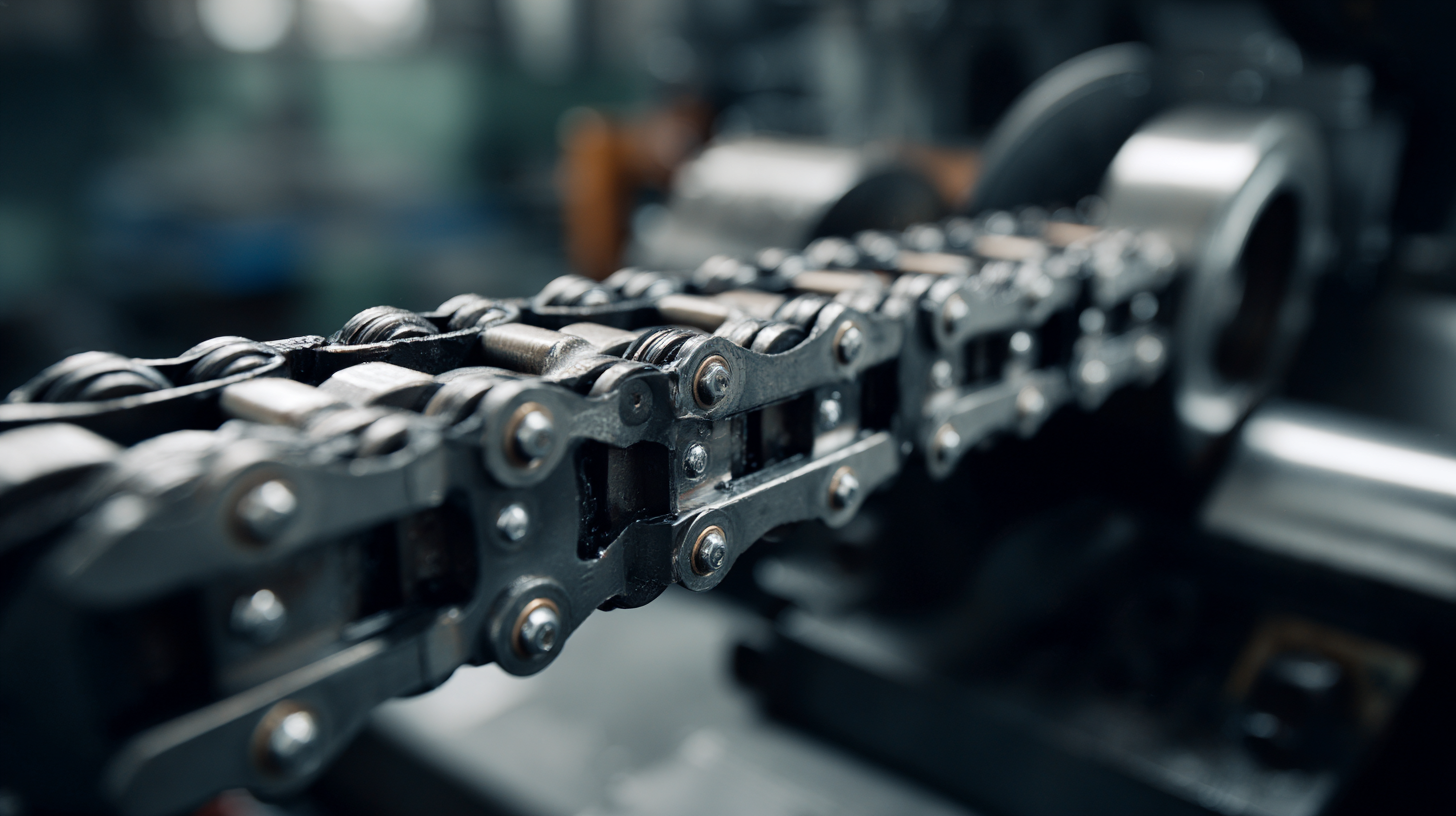

Bismark Chain Coupling Machines are integral to many industrial applications, offering robust solutions for power transmission. Understanding the fundamentals of these machines begins with recognizing their components and how they function together to ensure maximum efficiency. These machines consist of a chain that connects two gears, allowing for the transfer of torque while accommodating misalignment and reducing wear. The key to leveraging the full potential of Bismark Chain Coupling Machines lies in proper maintenance and suitable selection for specific applications.

As industries evolve, the importance of refining operational efficiency cannot be overstated. By adhering to best practices such as regular inspections, monitoring chain tension, and utilizing appropriate lubrication, businesses can greatly extend the lifespan of their Bismark Chain Coupling Machines. Furthermore, considering factors like load capacity and environmental conditions during the selection process can mitigate failures and optimize performance. The journey towards operational excellence starts with mastering the basics, ensuring that every component works in harmony to achieve peak efficiency.

In the realm of Bismark chain coupling systems, identifying common efficiency challenges can significantly enhance overall performance. One prevalent issue is the lack of real-time data on system performance. Implementing AI-driven operations forecasting can bridge this gap, providing insights that allow for proactive adjustments. With the ability to automate up to 50% of workforce management tasks, businesses can achieve cost reductions and optimize resource allocation, thereby alleviating pressure on maintenance and operational teams.

To maximize efficiency, regularly scheduling maintenance checks is essential. This simple practice can prevent minor issues from escalating into significant challenges. Moreover, employees should be trained to recognize and report inefficiencies in real-time, fostering an environment of continuous improvement. By encouraging a proactive approach to problem identification, organizations can ensure that their Bismark chain systems operate at peak efficiency, minimizing downtime and reducing costs. Adopting these practices not only enhances operational effectiveness but also builds a resilient framework capable of adapting to future challenges.

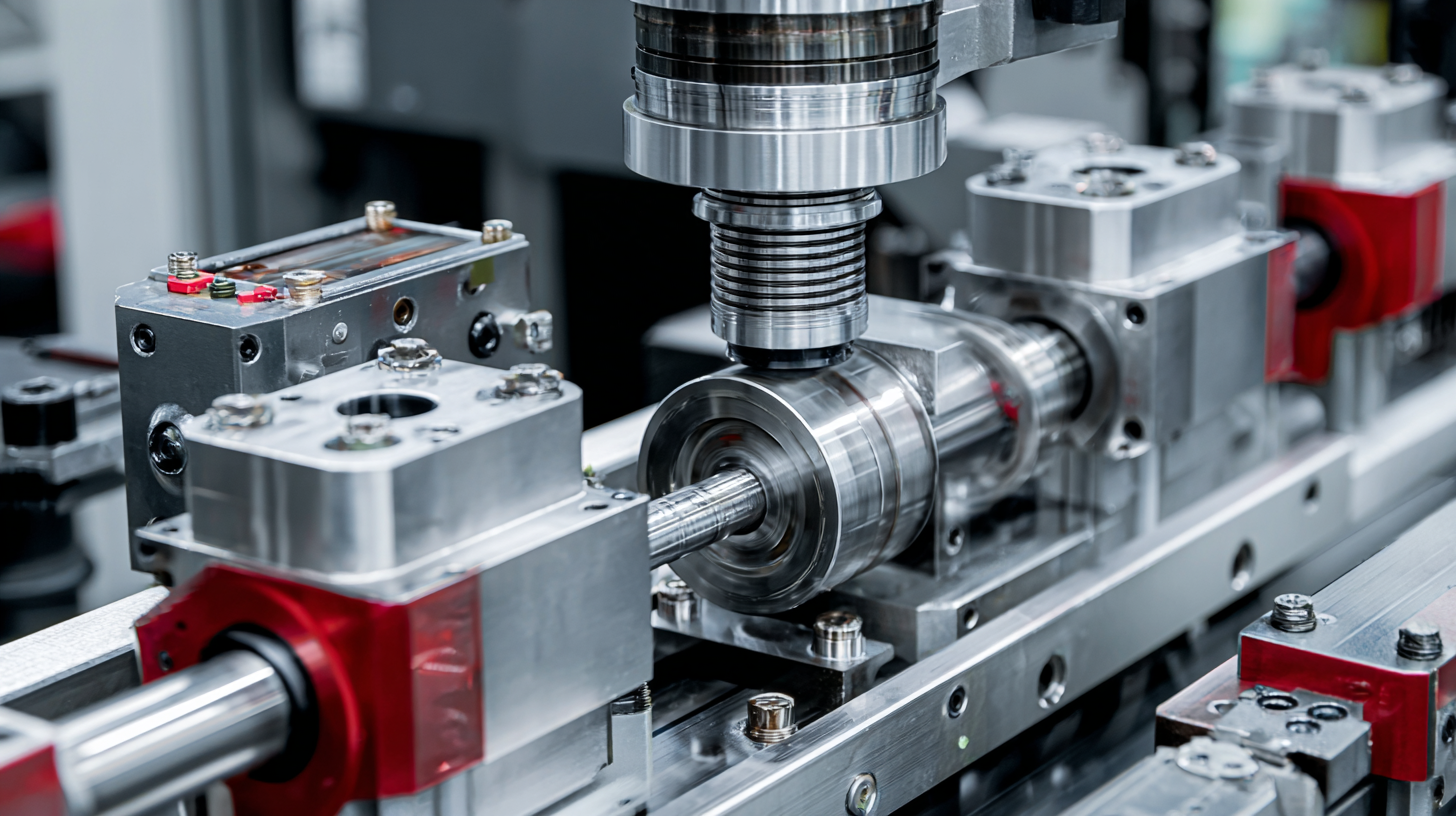

Maintaining optimal performance of the Bismark Chain Coupling Machine is crucial for maximizing efficiency in any operational setting. One of the essential maintenance practices is regular inspection of the coupling components. This involves checking for wear and tear, which can lead to increased friction and energy loss. By identifying and addressing these issues early, you can prevent unexpected downtime and extend the lifecycle of your machinery.

Another vital maintenance practice is ensuring proper lubrication. The chain coupling requires regular lubrication to minimize friction and enhance performance. Using the right type of lubricant can significantly reduce operational noise levels, prevent overheating, and improve overall efficiency. Additionally, it’s important to establish a routine lubrication schedule based on the machine's usage to maintain its peak performance consistently. Keeping a log of maintenance activities can also help in tracking the machine's condition and forecasting future maintenance needs efficiently.

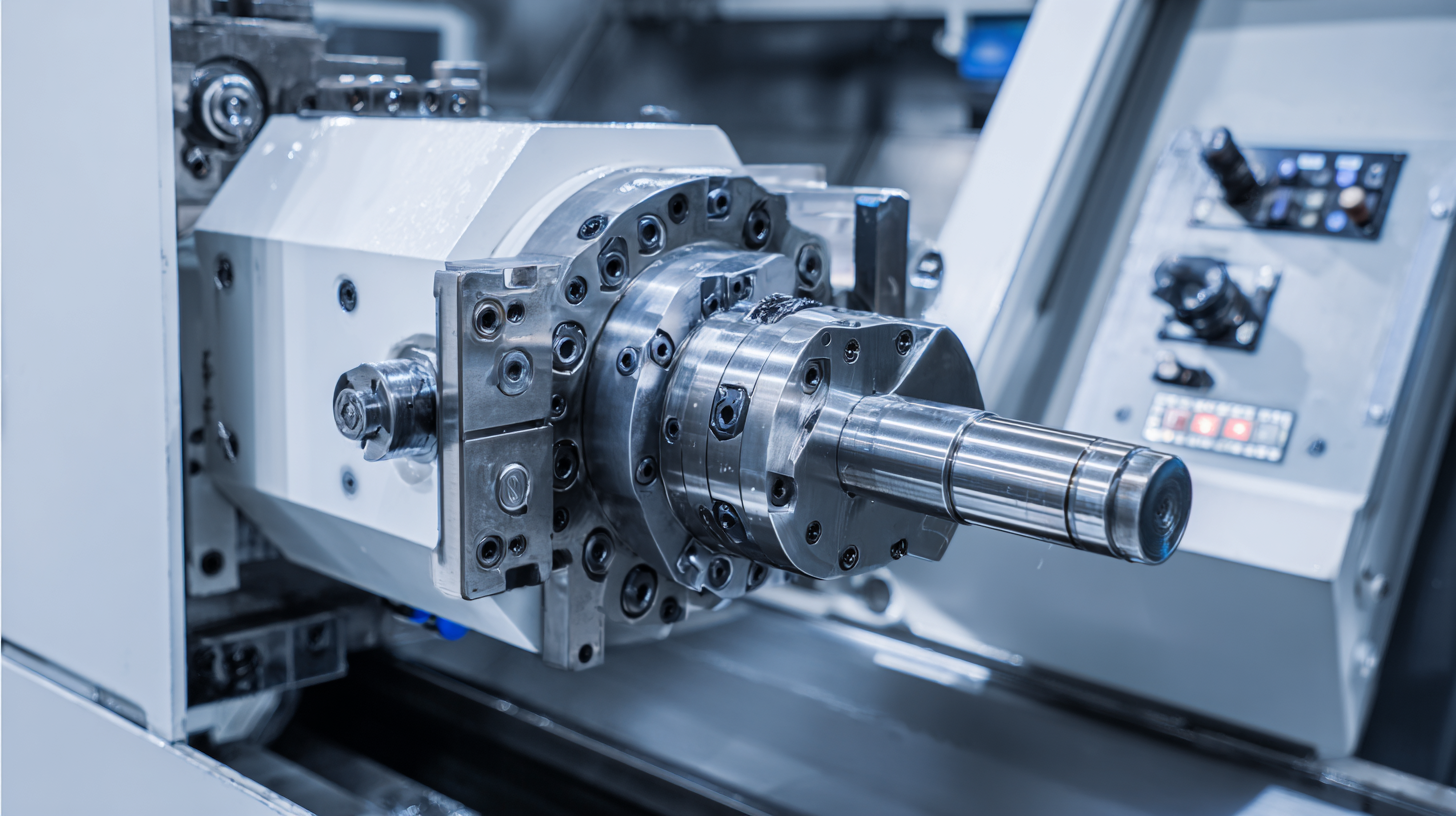

In the pursuit of maximizing efficiency in manufacturing, the integration of advanced technology in coupling machines is becoming increasingly essential. According to a recent report by MarketsandMarkets, the global coupling market is expected to reach $9.6 billion by 2025, driven by the rising demand for precision and reliability in machinery. By leveraging cutting-edge technologies such as IoT and AI, manufacturers can enhance the operational efficiency of Bismark Chain Coupling Machines, allowing for real-time monitoring and predictive maintenance. This shift not only minimizes downtime but also significantly reduces maintenance costs, aligning with the industry's goal of achieving operational excellence.

Moreover, incorporating automation into coupling machine processes can result in up to a 30% increase in productivity, as highlighted in a study by McKinsey & Company. Automated systems streamline workflows, reduce human error, and enhance the accuracy of coupling installations. Embracing digital tools enables manufacturers to analyze performance metrics and optimize their operations proactively. By investing in these technological advancements, businesses can ensure that their Bismark Chain Coupling Machines operate at peak efficiency, thus improving overall throughput and competitiveness in a rapidly evolving market.

| Practice | Description | Benefits | Technology Utilized |

|---|---|---|---|

| Regular Maintenance | Perform routine inspections and servicing of coupling machines. | Increases longevity and reduces downtime. | Predictive maintenance tools |

| Operator Training | Equip operators with knowledge on machine operation and safety. | Improves efficiency and reduces operational errors. | VR training simulations |

| Data Monitoring | Implement real-time monitoring of machine performance. | Allows for immediate response to performance issues. | IoT sensors |

| Quality Materials | Use high-grade materials for construction and parts. | Enhances durability and performance. | Material science advancements |

| Automation Integration | Incorporate automated systems for coupling operations. | Increases speed and precision. | Robotics |

| Performance Analytics | Analyze machine data to identify performance trends. | Facilitates informed decision-making. | Data analytics software |

| Feedback Loops | Create channels for operators to provide input on processes. | Enhances engagement and improvement suggestions. | Communication platforms |

Training and skill development for operators and technicians are paramount in maximizing efficiency when using Bismark Chain Coupling Machines. Research indicates that companies with comprehensive training programs see a 20% increase in productivity and a significant reduction in operational errors. According to a report by the Association for Manufacturing Technology, investing in operator training can boost machine utilization rates by up to 25%, translating directly into higher throughput and improved output quality.

Moreover, fostering a culture of continuous learning is essential for staying competitive in the industry. A study conducted by the American Society for Training & Development revealed that organizations that emphasize ongoing skills development are 2.5 times more likely to report higher employee engagement. For Bismark Chain Coupling Machines, this means not only equipping operators with basic machinery handling skills but also providing them with advanced training on troubleshooting, maintenance, and operational best practices. This holistic approach ensures that technicians are well-prepared to optimize machine performance and adapt to evolving technologies.