The world of jewelry making continues to thrive, with the global jewelry market projected to reach $480 billion by 2025, highlighting the growing interest in this art form. Among the essential skills for aspiring jewelers, soldering stands out as a fundamental technique that directly impacts the quality and durability of their creations.

Utilizing a Basic Jewelry Soldering Kit is critical for beginners, as it not only simplifies the process but also provides a solid foundation for mastering intricate designs. According to industry reports, the demand for handcrafted, personalized jewelry has surged, emphasizing the importance of honing soldering skills to meet consumer expectations.

By learning effective soldering techniques, artisans can elevate their craftsmanship, ensuring their products resonate with today’s discerning buyers while capitalizing on the booming market for unique jewelry pieces.

Jewelry soldering is an essential skill for anyone looking to create beautiful pieces from metal components. Understanding the basics of this technique is crucial for beginners who wish to embark on their jewelry-making journey. At its core, soldering involves melting a filler metal to join two or more pieces together. This process not only reinforces the structure of your creations but also opens the door to endless design possibilities.

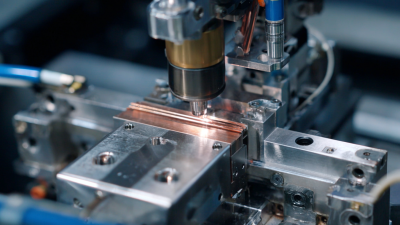

To get started, it's important to familiarize yourself with the necessary tools, such as a soldering iron, solder, flux, and a fireproof work surface. Preparing your pieces is equally vital; clean the surfaces to ensure a strong bond. Heat is applied with precision, allowing the solder to flow into the joint and create a sturdy connection. Practicing basic techniques like butt joints and lap joints will build your confidence and skill level, paving the way for more complex projects in the future. As you practice and refine your technique, you'll find that soldering becomes second nature, enabling you to realize your creative vision in metal.

Jewelry soldering is an essential skill for any aspiring artisan, and having the right tools and materials is crucial for achieving professional results. Our comprehensive jewelry soldering kit includes high-quality tools such as a soldering iron, flux, and various solder types, designed specifically for metalworking. According to a report by the Jewelry Security Council, the global jewelry market is valued at over $300 billion, which underscores the demand for well-crafted pieces that require precise soldering techniques.

In addition to the soldering iron, our kit includes crucial accessories like tweezers, soldering boards, and safety glasses. These tools not only improve efficiency but also ensure safety during the soldering process. A survey by the Jewelers of America found that 78% of jewelers believe that having specialized tools significantly enhances the quality of their work. By mastering these basics, jewelers can explore more intricate designs and expand their creative potential in a rapidly growing industry. With the right foundation, your journey into jewelry making can lead to beautifully crafted pieces that resonate with customers and collectors alike.

When embarking on the journey of jewelry soldering, it is crucial to recognize common mistakes that can hinder your progress and lead to unsatisfactory results. According to the Jewelry Crafting Association, approximately 30% of novice jewelers report struggling with improper soldering techniques, resulting in a higher rate of project failures and material waste. The most prevalent error is overheating the metal, which can cause brittleness and destroy delicate pieces. Using the correct solder for the type of metal being joined is also vital; mixing solders can lead to weak joints that are likely to break under stress.

Another frequent pitfall involves not properly preparing the surfaces that will be soldered. A study published in the Journal of Jewel Crafting Technology highlighted that over 40% of soldering mishaps stem from inadequate surface cleaning. Oils, dirt, and oxidization on metal can prevent the solder from flowing smoothly, leading to weak connections. To avoid these issues, it's essential to use appropriate cleaning methods, such as pickling or abrasive cleaning, prior to the soldering process. Prioritizing these foundational steps can dramatically improve the strength and appearance of your jewelry pieces.

| Mistake | Description | How to Avoid |

|---|---|---|

| Insufficient Cleaning | Not cleaning the metal pieces properly before soldering can prevent a strong bond. | Use a stainless steel brush or use pickle solution to clean metals effectively. |

| Overheating the Metal | Applying too much heat can cause oxidation or warp the metal. | Control your torch and practice heating the metal from a distance before applying direct flame. |

| Wrong Solder Type | Using solder that does not match the metals being joined can lead to weak joints. | Always select solder that is appropriate for the metal type (e.g., silver solder for silver pieces). |

| Not Enough Flux | Insufficient flux can result in poor flow of solder and weak joints. | Apply a generous amount of flux before soldering to ensure proper bonding. |

| Improper Setup | Poor alignment of pieces can cause misalignment after soldering. | Take the time to properly align and secure pieces before applying heat. |

Jewelry soldering is an intricate process that requires not only skill but also strict adherence to safety precautions to ensure a secure and efficient workspace. According to the Occupational Safety and Health Administration (OSHA), about 90% of workplace injuries can be prevented with proper safety measures in place. In jewelry making, this begins with the right personal protective equipment (PPE). Always wear safety glasses to protect your eyes from flying debris, and heat-resistant gloves to avoid burns from hot metal or tools.

Additionally, it's crucial to maintain a well-ventilated area when soldering. The fumes produced from solder and flux can be harmful over time. The National Institute for Occupational Safety and Health (NIOSH) emphasizes that proper ventilation can drastically reduce the concentration of harmful substances in your workspace. Invest in a fume extraction system or ensure that windows are open and fans are in place to facilitate air circulation.

Tips: Before starting your soldering project, lay out all tools and materials in a tidy manner to minimize hazards. Regularly check for gas leaks if you are working with a propane torch, and always have a fire extinguisher nearby. Taking these precautions not only protects your health but enhances your overall jewelry-making experience.

In recent years, DIY jewelry making has surged in popularity, driven by a growing desire for individuality and self-expression. As trends shift towards customized pieces, many enthusiasts are turning to hands-on techniques to create unique jewelry that reflects their personal style. This rising demand has not only fueled creativity but has also led to an increase in educational resources and tools available to budding jewelers, making it easier than ever to start crafting stunning pieces at home.

The expansion of the DIY jewelry market is also fueled by social media platforms, where creators showcase their work and connect with a broader audience. Online tutorials, workshops, and communities have emerged, providing invaluable support for those looking to master the intricate skills of jewelry making, including soldering. With the right equipment, such as a comprehensive jewelry soldering kit, aspiring artisans can experiment with different designs and materials, pushing the boundaries of traditional jewelry craftsmanship. As this trend continues to grow, we can expect an ever-diversifying array of styles and techniques in the jewelry-making landscape.