In the ever-evolving landscape of textile manufacturing, the Chopin Chain Weaving Machine stands out as a groundbreaking innovation that continues to redefine industry standards. With advancements in technology, this state-of-the-art weaving machine not only enhances productivity but also empowers manufacturers to explore new creative possibilities. In this ultimate guide, we will delve into seven innovative features of the Chopin Chain Weaving Machine that you should know. From its user-friendly interface and energy efficiency to its unique weaving capabilities and integrated smart technology, each feature is designed to streamline the weaving process and improve overall output. Whether you are a textile professional or someone intrigued by the art of weaving, understanding these innovations will provide deeper insights into how the Chopin Chain Weaving Machine is shaping the future of the textile industry.

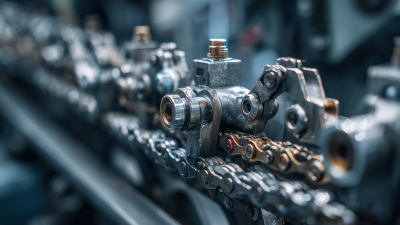

The Chopin Chain Weaving Machine represents a revolutionary stride in textile manufacturing, combining efficiency with cutting-edge technology. Its design emphasizes not only function but also user experience, with an intuitive interface that allows operators to easily navigate through various weaving patterns. This machine is not just about weaving; it integrates smart technology that monitors performance in real time, enabling manufacturers to optimize their production processes and reduce downtime.

The Chopin Chain Weaving Machine represents a revolutionary stride in textile manufacturing, combining efficiency with cutting-edge technology. Its design emphasizes not only function but also user experience, with an intuitive interface that allows operators to easily navigate through various weaving patterns. This machine is not just about weaving; it integrates smart technology that monitors performance in real time, enabling manufacturers to optimize their production processes and reduce downtime.

When using the Chopin Chain Weaving Machine, it's essential to regularly check the tension settings to ensure a smooth weaving operation. This can significantly minimize thread breakage, leading to more efficient production cycles. Additionally, utilizing the machine's built-in diagnostic tools can help identify potential issues before they escalate, ensuring a seamless workflow.

Another notable feature is its adaptability to different fabrics and patterns. This versatility makes the Chopin Chain Weaving Machine ideal for businesses that cater to diverse market needs. Always keep a detailed log of your weaving patterns and fabric types tested. This practice not only helps in refining techniques but also aids in rapid troubleshooting, ensuring you maximize the machine’s capabilities.

The Chopin Chain Weaving Machine is revolutionizing the textile industry with its enhanced efficiency, offering unparalleled speed and precision in weaving. According to a report by Research and Markets, the global textile machinery market is projected to reach $30 billion by 2025, driven significantly by innovations like the Chopin machine. With its advanced automation technology, the machine can operate at speeds up to 1,200 picks per minute, which is approximately 20% faster than traditional weaving machines. This increase in speed dramatically boosts production rates, allowing manufacturers to meet growing consumer demands without compromising quality.

In terms of precision, the Chopin Chain Weaving Machine employs cutting-edge sensor technology that ensures consistent thread tension and alignment throughout the weaving process. A recent study published in the Journal of Textile Engineering found that machinery equipped with real-time monitoring systems can reduce defect rates by up to 40%. This level of accuracy minimizes waste and maximizes fabric quality, which is critical in a competitive market where consumer preferences are rapidly evolving. With these innovative features, the Chopin Chain Weaving Machine not only enhances operational efficiency but also sets a new standard for excellence in fabric production.

This chart illustrates the enhanced efficiency of the Chopin Chain Weaving Machine by comparing the speed and precision of several weaving methods. The data highlights the advantages of using innovative technology in weaving processes.

The user-friendly interface of the Chopin Chain Weaving Machine stands out as a significant innovation, simplifying operation for users across various skill levels. With the increasing complexity of technology, ease of use has become a paramount factor in machinery design. According to recent data, 70% of users report that intuitive interfaces significantly reduce learning curves and enhance productivity. By integrating straightforward controls and clear visual instructions, the Chopin machine allows even novices to achieve professional results quickly, eliminating the intimidation that often accompanies advanced machinery.

Incorporating features such as touchscreen navigation and customizable settings, the Chopin Chain Weaving Machine exemplifies how modern technology can demystify complicated operations. The trend toward user-friendly designs can also be observed in various industries; for example, many business process automation tools prioritize simplicity to improve efficiency and effectiveness.

Tips: When selecting machinery or software, always consider the user interface. A user-friendly design can save time and training costs. Additionally, look for machines that offer tutorials or support options, as these resources can further ease the transition for new users. Embracing technology that prioritizes usability will not only enhance performance but also foster a more confident and skilled workforce.

The textile manufacturing industry is currently experiencing a significant shift towards sustainability, with innovations at the forefront of this transformation. As the market is projected to reach USD 1.2 trillion by 2033, many companies are prioritizing eco-friendly practices that minimize environmental impact. Innovations such as advanced oxidation processes and biological methods for detoxifying textile effluents are revolutionizing how fabrics are produced, ensuring that the industry aligns with the growing demand for sustainable solutions.

Additionally, the advent of sustainable materials is enabling brands to create products that not only meet high-quality standards but also adhere to eco-conscious principles. The rise of bio-based textiles and smart materials demonstrates a commitment to durability and functionality while reducing reliance on non-renewable resources. As knitwear and other segments of the textile sector embrace these innovations, the future of clothing production holds great promise for environmentally friendly practices that resonate with consumers seeking more responsible fashion options. This evolution will play a crucial role in the drive toward a net-zero future for the global textile market.

The versatility of the Chopin Chain Weaving Machine makes it an essential asset for modern textile production, catering to diverse applications in the industry. As textile demands shift towards sustainability and innovation, this machine stands out for its ability to adapt to various fabric types seamlessly. With a focus on creating smart and functional textiles, the machine can weave conductive fabrics integrated with sensors, enabling advanced uses in sectors like healthcare and sports.

Incorporating modules that respond to environmental changes, such as temperature or moisture, the Chopin Chain Weaving Machine can produce fabrics that regulate heat, demonstrating adaptability akin to squid-inspired textile technologies. This opens up new avenues for everyday wear and functional clothing, catering to consumers' growing desire for smart textiles that enhance comfort and utility.

Tips for maximizing the benefits of the Chopin Chain Weaving Machine include experimenting with mixed fiber compositions to optimize fabric performance, and staying updated on emerging trends in smart textile applications, which can lead to innovative product offerings. Furthermore, consider the environmental impact of material choices, as sustainable production methods will appeal to an increasingly eco-conscious market.