In the competitive landscape of modern jewelry manufacturing, the significance of an Automatic Stone Setting Machine cannot be overstated. According to recent industry reports, the global jewelry market is expected to reach USD 480 billion by 2025, with automation playing a pivotal role in meeting the increasing demand for precision and efficiency. As artisans strive to enhance productivity while maintaining quality, the selection of the right stone setting machine becomes crucial. The adoption of advanced automatic setting technology not only reduces labor costs by up to 30% but also minimizes the risk of human error, ensuring a flawless finish for every piece. This comprehensive guide aims to equip you with the necessary insights and considerations for selecting your ideal Automatic Stone Setting Machine, ultimately empowering your business to thrive in this dynamic market.

When choosing an automatic stone setting machine, several key factors should be considered to ensure you select the ideal model for your needs. First, evaluate the overall quality and durability of the machine. Look for options that use robust materials and have a solid construction to withstand the demands of frequent use. A reliable machine will not only perform better but will also save you money on repairs and replacements in the long run.

Another important consideration is the ease of use. The machine should have an intuitive interface that allows for smooth operation, even for beginners. Pay attention to customer reviews about the user-friendliness of different models. Additionally, consider the size and capacity of the machine, ensuring it fits comfortably in your workspace while providing enough output to meet your production needs.

**Tips:**

- Always prioritize machines with safety features, such as automatic shut-off functions and protective guards.

- Take advantage of warranty offers; this can give you peace of mind and security in your investment.

- Don’t forget to consider the availability of parts and customer support, as these can significantly impact your machine's performance and longevity.

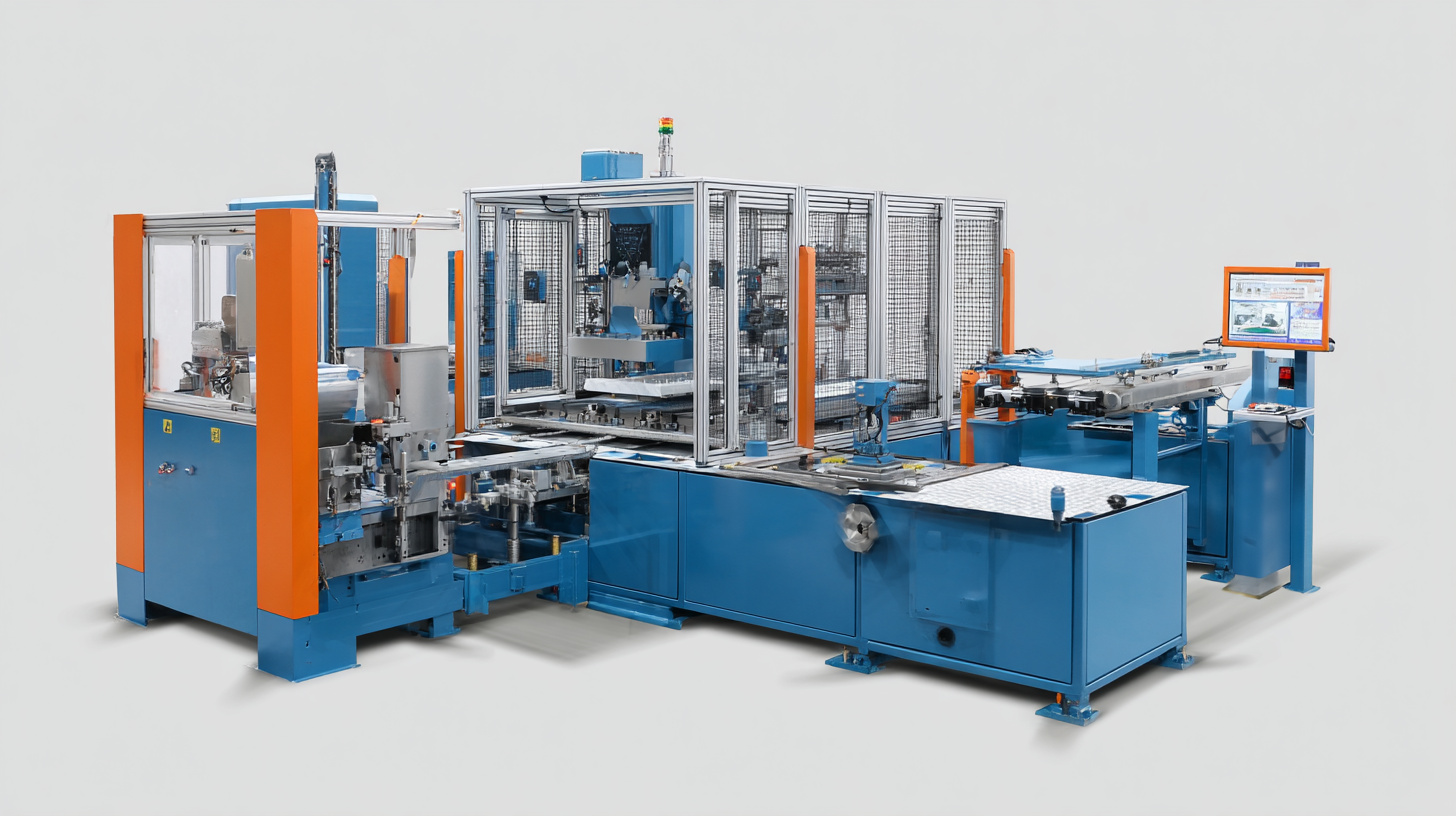

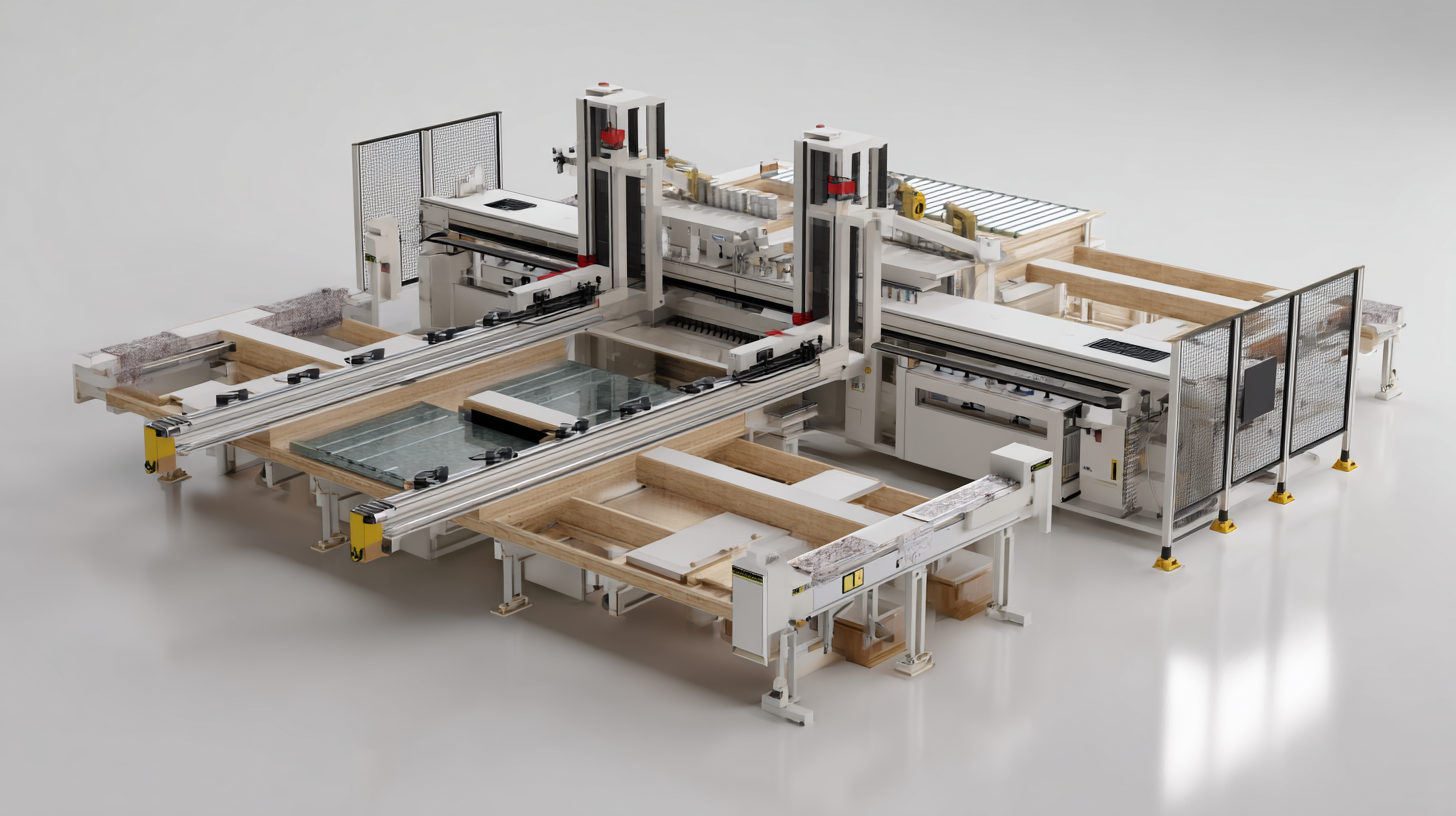

When it comes to selecting an automatic stone setting machine, understanding the different types available is crucial. There are primarily three categories: semi-automatic machines, fully automatic machines, and high-speed machines. Semi-automatic machines typically require manual intervention for loading and unloading stones, making them ideal for small-scale operations where flexibility is key. Fully automatic machines, on the other hand, streamline the setting process with advanced technology, allowing for higher production rates and consistent quality – perfect for larger enterprises looking to maximize efficiency.

When considering which type to choose, it’s essential to evaluate your specific production needs and the types of stones you work with. For instance, if you frequently handle various sizes of stones, a semi-automatic machine may offer the versatility you require. Additionally, ensure that the machine is easy to maintain, as this can impact your operational efficiency over time.

Tip: Always check for user-friendly features such as touchscreen interfaces and programmable settings that cater to different stone specifications, enhancing both usability and output quality. Another important consideration is the machine's warranty and support services provided by the manufacturer, as this can be a deciding factor in your long-term satisfaction and operational continuity.

When selecting an ideal automatic stone setting machine, it's crucial to focus on key features that enhance productivity and ensure precision. One of the most significant attributes to consider is the machine's automation level. According to a recent industry report by the International Gem Society, fully automated machines can increase productivity by up to 30% compared to semi-automatic models. This is particularly vital for manufacturers looking to meet rising demand while maintaining high-quality standards.

Another essential feature is the machine's adaptability to various stone sizes and types. A versatile machine can handle multiple settings and styles, which is critical in the competitive jewelry market. The Gemological Institute of America reports that versatile setting machines reduce the need for manual intervention, thereby decreasing labor costs by approximately 25%. Furthermore, the integration of advanced technology, such as precision laser systems, allows for cleaner and more secure settings, which has been shown to enhance customer satisfaction considerably. By prioritizing these features, jewelers can select a machine that not only meets their current needs but also positions them for future growth.

When selecting the ideal automatic stone setting machine, it's important to consider the brands and models currently leading the market. Some prominent names have gained recognition for their reliability and innovation, making them popular choices among jewelers. It’s essential to evaluate the specific features each brand offers, such as speed, accuracy, and ease of use, to find the best fit for your needs.

**Tips for Choosing the Right Machine:**

1. Look for machines that offer a variety of settings for different stone sizes and shapes. Versatility can be a significant advantage if your jewelry design requires eclectic styles.

2. Pay attention to user reviews and testimonials. Machines that have a strong reputation for durability and performance tend to minimize long-term costs and increase productivity.

In addition to established brands, consider newer models that may provide advanced technology, such as automated programming features or enhanced precision settings. Staying informed about the latest advancements can lead you to a machine that not only meets your current demands but also adapts to future trends in stone setting.

Proper maintenance of your automatic stone setting machine is crucial for ensuring its longevity and optimal performance. Regularly cleaning the machine is the first step in this process. Dust and residue can accumulate over time, affecting both the precision and efficiency of the setting process. Use a soft cloth and a suitable cleaning solution to wipe down all external surfaces. Additionally, it's essential to check the internal components regularly. Schedule routine inspections to identify any signs of wear or damage, which can avert costly repairs down the line.

Lubrication is another key aspect of maintenance that cannot be overlooked. Ensure that all moving parts are properly lubricated according to the manufacturer's guidelines. This will help in reducing friction and preventing overheating, which can lead to mechanical failures. It's also wise to keep the machine’s software updated, as manufacturers may release updates that improve functionality and performance. By establishing a consistent maintenance routine, you can ensure that your automatic stone setting machine operates at its best, delivering the high-quality results you expect.