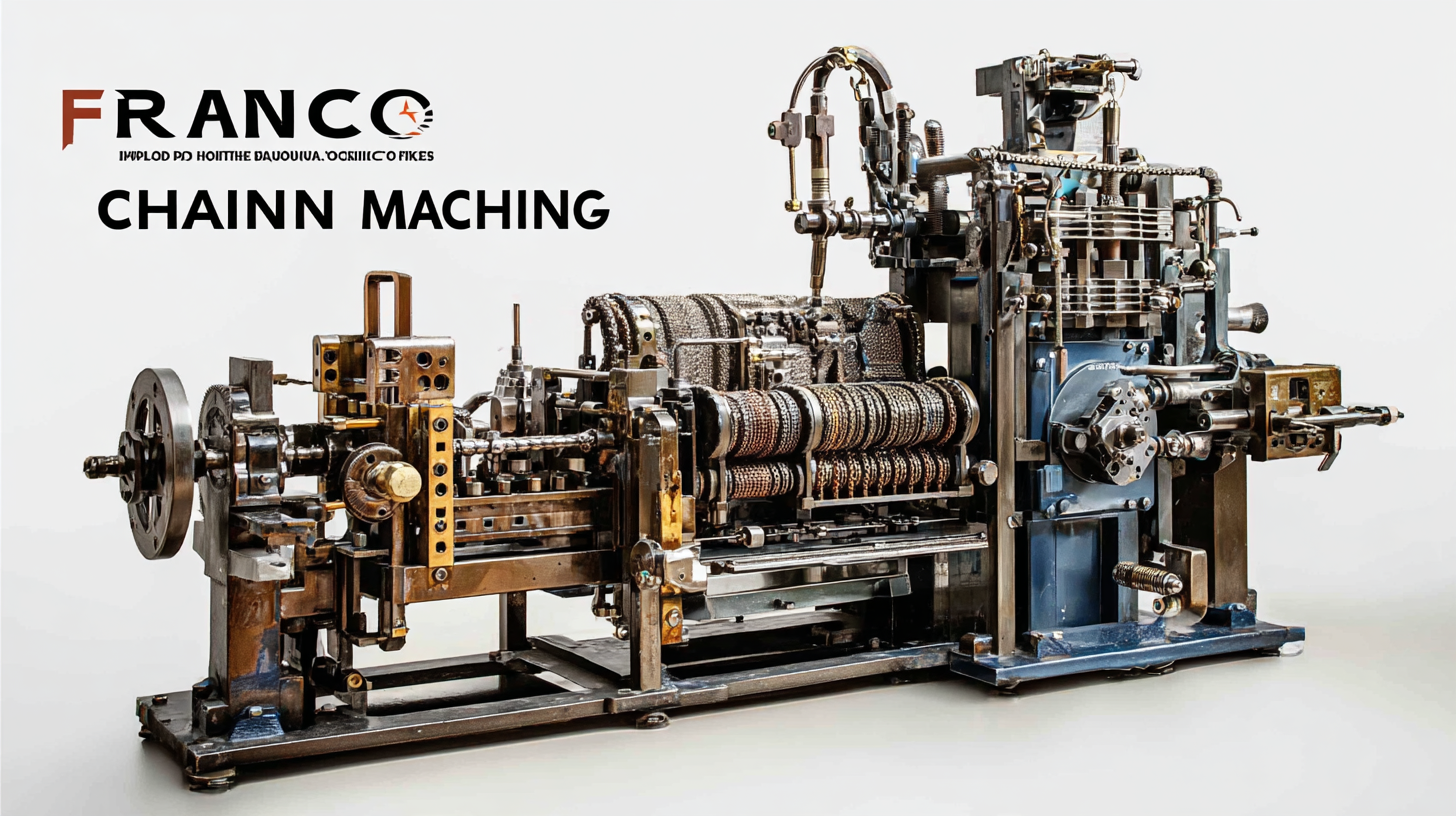

In today's interconnected world, businesses are constantly seeking innovative solutions to enhance their production capabilities and expand their market presence. One such solution is the Franco Chain Making Machine, a cutting-edge technology revolutionizing the jewelry and accessory manufacturing industry. As demand for high-quality chains continues to soar, manufacturers are turning to reliable machines that not only optimize production efficiency but also ensure superior craftsmanship.

This blog will explore the detailed technical parameters of the best Franco Chain Making Machines available from China's premier manufacturers, highlighting their versatile features and performance capabilities. Additionally, we will provide practical insights on how to choose the right machine for specific manufacturing needs, unlocking global opportunities for both small enterprises and large-scale industries.

Join us as we delve into the world of Franco Chain Making Machines and pave the way for your business to thrive in the competitive global market.

When it comes to manufacturing high-quality Franco chains, selecting the right chain making machine is crucial for achieving optimal results. China's premier manufacturers offer a range of specialized machines designed to cater to diverse production needs. These machines boast advanced technology that enhances efficiency, precision, and overall output quality. Features such as programmable settings allow for customized chain designs, enabling manufacturers to meet specific market demands effectively.

One standout feature of top Franco chain making machines is their user-friendly interfaces, making them accessible for operators with varying levels of experience. Additionally, many machines incorporate automation, reducing manual labor and minimizing the risk of errors during production. This not only streamlines the manufacturing process but also helps in maintaining consistent quality across large batches. With robust construction and the ability to handle various metal types, these machines represent a smart investment for businesses looking to expand their production capabilities in the global market.

Investing in high-quality Franco chain production equipment offers numerous advantages for manufacturers looking to expand their market reach. One significant benefit is the enhanced efficiency these machines provide. Advanced technology and precision engineering allow for faster production cycles, reducing downtime and increasing overall output. This efficiency can lead to significant cost savings while ensuring that businesses can meet increasing demand without sacrificing quality.

Moreover, top-tier Franco chain making machines from China's premier manufacturers are designed for durability and reliability. These machines undergo rigorous testing and quality control processes, which means they can handle continuous operation without frequent breakdowns. This reliability minimizes maintenance costs and interruptions, enabling manufacturers to maintain a steady flow of production. Additionally, many of these machines come equipped with user-friendly interfaces and automated features, making them easy to operate and reducing the need for extensive training. Ultimately, investing in superior production equipment empowers businesses to not only meet current demands but also strategically position themselves for future growth in the global market.

| Feature | Details | Benefits |

|---|---|---|

| Production Speed | Up to 100 meters per minute | Increased output and efficiency |

| Material Compatibility | Compatible with various metals | Versatility in production |

| Automation Level | Fully automated operation | Reduced labor costs |

| Energy Efficiency | Low power consumption | Lower operational costs |

| User Interface | Intuitive touch screen controls | Ease of use and training |

| Maintenance | Minimal maintenance required | Increased uptime and productivity |

In the realm of jewelry manufacturing, Franco chain machines have emerged as essential tools for producing high-quality chains that are both durable and stylish. A recent industry report indicates that the demand for Franco chains has been steadily increasing, with a projected growth rate of 7% annually over the next five years in the global jewelry market. This growth underscores the significance of choosing the right machinery to meet production needs efficiently.

China is home to several leading manufacturers that have established a reputation for delivering top-tier Franco chain making machines. These manufacturers leverage cutting-edge technology and expertise, producing machines that offer enhanced precision and speed. For instance, a comparative analysis of the top five manufacturers shows that companies such as Xinchang and Zhuhai not only provide innovative designs but also ensure compliance with international standards, contributing to their competitive edge. Reports have highlighted that machines from these manufacturers can increase production capacity by up to 30%, making them invaluable assets for businesses looking to expand their reach in the global marketplace.

In today's fast-paced manufacturing landscape, maximizing production efficiency is crucial for staying competitive. Advanced Franco chain technology emerges as a game-changer, streamlining the production process while ensuring high-quality output. The best Franco chain making machines from China’s premier manufacturers are specifically designed to enhance productivity, allowing manufacturers to meet growing market demands without compromising on quality. These state-of-the-art machines integrate smart automation and precision engineering, enabling streamlined operations and minimizing downtime.

Moreover, the advanced features of these Franco chain machines facilitate rapid adaptability to various production requirements. Manufacturers can easily switch between different chain specifications, ensuring flexibility in meeting diverse customer needs. Enhanced automation also reduces labor costs and increases safety on the factory floor. Investing in top-notch Franco chain technology is not just about upgrading machinery—it's about unlocking a new level of production efficiency that empowers businesses to scale and seize global opportunities effectively. By embracing these innovations, manufacturers position themselves at the forefront of their industry, ready to tackle challenges and capitalize on emerging trends.

As global markets evolve, the demand for specialized machinery like the Franco Chain Making Machine is significantly influenced by broader trends across various sectors. The current shift towards sustainability and resource optimization in industries such as mushroom processing exemplifies the need for innovative equipment that caters to evolving production requirements. The focus on circular economies encourages manufacturers to invest in machines that not only enhance productivity but also contribute to environmental conservation, suggesting a similar trajectory for Franco chain manufacturing.

Furthermore, the integration of advanced technologies, such as artificial intelligence, is reshaping manufacturing landscapes. This shift towards Industry 4.0 is driving the innovation and enhancement of machinery like the Franco Chain Machine, enabling manufacturers to streamline operations and adapt to changing market demands. As companies increasingly look to optimize energy consumption and improve production efficiency, the role of cutting-edge machinery becomes even more critical. These trends highlight the necessity for manufacturers to remain agile and leverage technological advancements to stay competitive in the global marketplace.