In recent years, the jewelry and manufacturing industries have witnessed a significant transformation, largely driven by advancements in technology. Among the innovations that are reshaping these sectors is the Automatic Chain Making Machine, a game-changer that enhances production efficiency and product quality. As we look ahead to the technological trends of 2025, it becomes increasingly evident why the demand for such machines is on the rise globally. These state-of-the-art devices not only streamline the chain production process but also offer versatility and cost-effectiveness that are crucial for businesses aiming to stay competitive. This blog will explore five key applications of the Automatic Chain Making Machine in 2023, shedding light on its impact and the reasons behind its growing global acceptance.

Automatic chain making machines are transforming the jewelry industry in unprecedented ways. As the demand for unique and customizable jewelry surges, these advanced machines are at the forefront of revolutionizing production processes. By incorporating machine learning and artificial intelligence, manufacturers are able to enhance design precision and streamline operations. This innovative technology not only increases efficiency but also allows for greater creativity in jewelry design, enabling artisans to explore new forms and styles that were previously unattainable.

Furthermore, the integration of automation in chain production enhances supply chain dynamics, making it easier for jewelry producers to respond to market demands with agility. The data-driven insights provided by AI enable manufacturers to optimize their workflows, ensuring that resources are allocated effectively and that inventory remains manageable. This shift toward automated processes not only improves productivity but also elevates the overall quality of the final products, meeting the discerning tastes of today’s consumers. The evolution of these machines reflects a broader trend in manufacturing, where automation and AI are key drivers of growth and innovation in the jewelry sector.

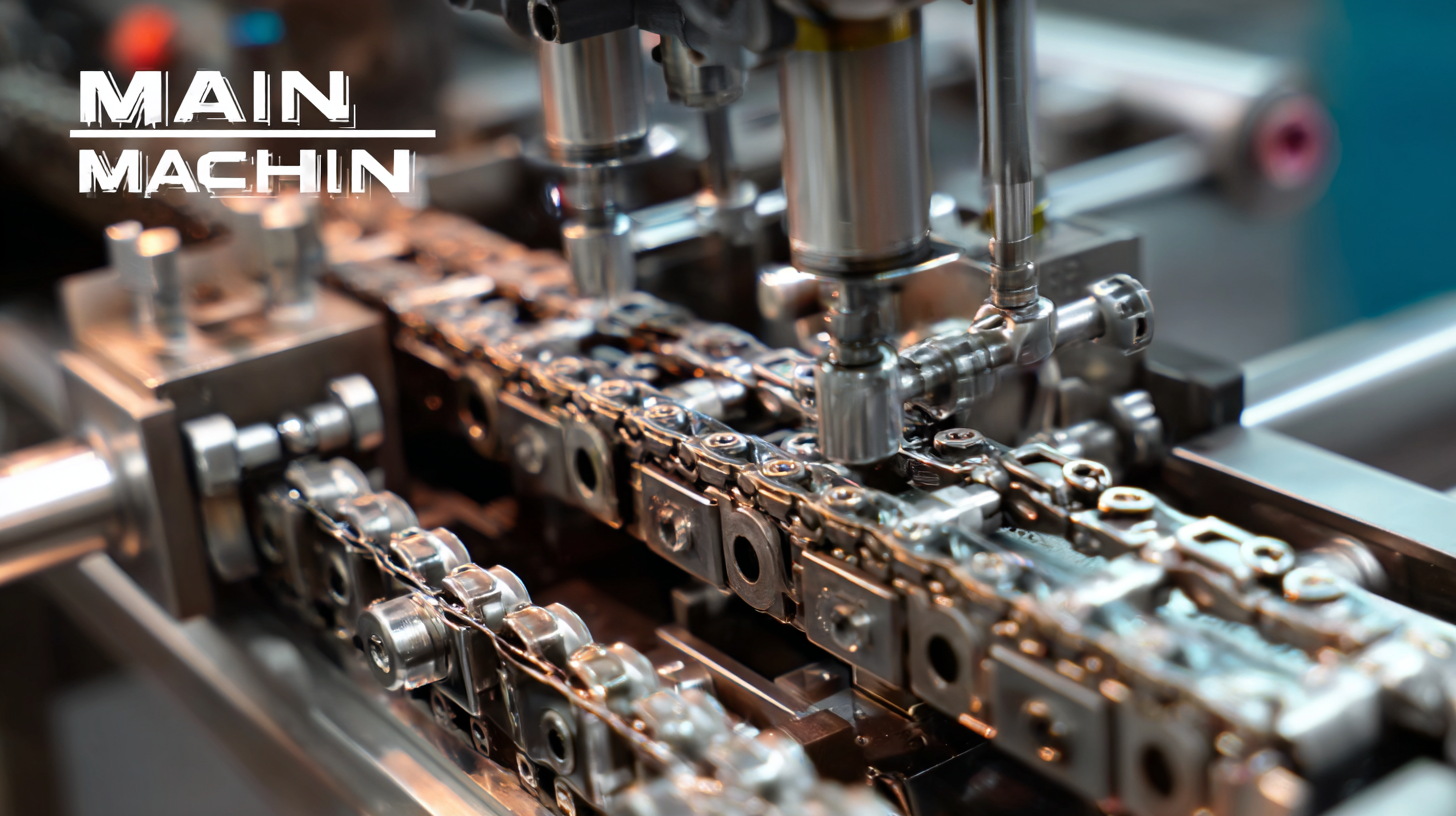

Automatic chain making machines have revolutionized the jewelry and manufacturing industries, offering unparalleled efficiency and precision. These advanced machines utilize cutting-edge technology, automating the entire process of chain production from raw material feeding to final assembly. The operation begins with the feeding of metal wire into the machine, where it is precisely cut and shaped into links using high-speed dies. This mechanization not only increases the speed of production but also significantly reduces labor costs and human error associated with manual craftsmanship.

Equipped with sophisticated programming capabilities, modern automatic chain making machines can produce a variety of chain types, including intricate designs and varying link sizes, all while maintaining consistent quality. Sensors and smart technology enable real-time monitoring of the production process, ensuring that any issues are immediately addressed. The versatility and productivity of these machines cater to the surging global demand for customized jewelry and industrial chains, making them an indispensable asset in today's fast-paced market. As industries continue to embrace automation, the impact of these machines on production efficiency and product quality becomes increasingly evident.

In 2023, the global market for chain manufacturing equipment has experienced significant growth, driven by several key trends. The rising demand for automatic chain making machines is largely attributed to industries seeking increased efficiency and lower operational costs. As businesses aim to streamline production processes, the investment in advanced machinery has become a top priority. This shift not only meets the rising consumer demands but also enhances productivity, making it vital for manufacturers to stay competitive in a fast-evolving marketplace.

When considering the adoption of new machinery, companies should focus on several important tips. First, evaluate the specific needs of your production line. Understanding how different machines can optimize workflows is crucial. Second, consider investing in machines that offer versatility, allowing for the production of various chain types without requiring extensive retooling. Lastly, ensure that training and support are part of your machinery investment; well-trained operators can significantly enhance production efficiency and quality.

The global demand for chain manufacturing equipment is also influenced by technological advancements. Automation and smart technology integration are reshaping manufacturing processes, further driving the need for sophisticated chain making machines. Manufacturers adopting these technologies benefit from improved accuracy, reduced waste, and better overall product quality, solidifying their position in the competitive landscape.

In today's fast-paced manufacturing environment, investing in automatic chain making machines has become a pivotal strategy for businesses aiming to enhance efficiency and precision. These advanced machines leverage sophisticated technology to produce high-quality chains rapidly, significantly reducing production time compared to traditional methods. This efficiency not only lowers operational costs but also allows manufacturers to meet increasing global demand without compromising on quality.

Moreover, the precision offered by automatic chain making machines ensures that every product meets stringent quality standards. With the ability to maintain uniformity across large production runs, businesses can minimize defects and improve overall product reliability. This results in higher customer satisfaction and can lead to stronger brand loyalty. As companies seek to optimize their operations in 2023, the automatic chain making machine stands out as a transformative investment, driving productivity and establishing a competitive edge in the marketplace.

This bar chart illustrates the key benefits of investing in the best automatic chain making machines in 2023. The data shows high levels of efficiency and precision, along with significant advantages in cost reduction, labor savings, and enhanced production speed, reflecting the global demand for these machines.

China has solidified its position as a global leader in automatic chain manufacturing, driven by significant advancements in technology and production capacity. According to a recent report by MarketsandMarkets, the automatic chain market is projected to grow at a CAGR of 4.9% between 2023 and 2028, with China accounting for over 30% of global production. The integration of smart manufacturing techniques has enabled Chinese manufacturers to achieve higher efficiency and lower production costs, making their products increasingly attractive to international buyers.

In this dynamic landscape, companies looking to leverage these advancements should consider investing in the latest automatic chain making machines. Not only do these machines enhance production speed, but they also ensure precision and consistency, critical factors in meeting global quality standards. Additionally, exploring partnerships with Chinese manufacturers could provide businesses with competitive pricing and access to innovative production methods.

Tips: When sourcing automatic chains, prioritize suppliers with strong track records in quality assurance and timely delivery. Engaging in regular performance evaluations of your suppliers can help maintain optimal supply chain efficiency. Finally, staying informed about the latest technological trends in automatic chain production can enable businesses to adapt and remain competitive in an evolving market.