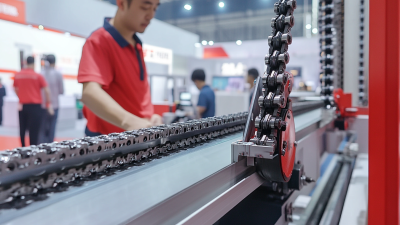

In the rapidly evolving landscape of global production, the Ball Chain Coupling Machine emerges as a pivotal innovation that enhances manufacturing efficiency and adaptability. With the increasing demand for precision and reliability in various industries, this machine stands out due to its unique ability to create seamless connections between components, thereby optimizing workflows and reducing downtime. As businesses strive to meet the challenges of a competitive marketplace, the implementation of Ball Chain Coupling Machines offers numerous benefits, including improved accuracy, streamlined operations, and significant cost savings. This blog will delve into the future prospects of these machines, exploring their advantages and potential impact on global production processes. By understanding the transformative power of Ball Chain Coupling Machines, manufacturers can position themselves for success in the dynamic industrial landscape ahead.

The integration of automation into the production processes of ball chain coupling machines is reshaping the landscape of global manufacturing. As countries like China emerge as leaders in advanced industries, the efficiencies gained through automated systems are proving to be crucial. Enhanced precision and speed in production not only reduce operational costs but also enable manufacturers to meet the growing demand for high-quality components. This is particularly significant in industries such as automotive and aerospace, where reliability is paramount.

Tips for enhancing efficiency with automation include investing in smart technology that can monitor and adjust production parameters in real time. Additionally, training personnel to work alongside automated systems is vital to maximize the potential of these machines. By fostering a culture of innovation and continual improvement, manufacturers can better adapt to the fast-evolving market dynamics.

Furthermore, collaborating with tech innovators can lead to breakthroughs in machine design and functionality. Embracing such partnerships will ensure that manufacturers remain competitive while driving forward the development of ball chain coupling machines that are not only efficient but also environmentally sustainable. As automation continues to take center stage, the future of these machines in global production looks promising.

This chart illustrates the efficiency of ball chain coupling machines in global manufacturing from 2018 to 2023, highlighting the impact of automation on production efficiency.

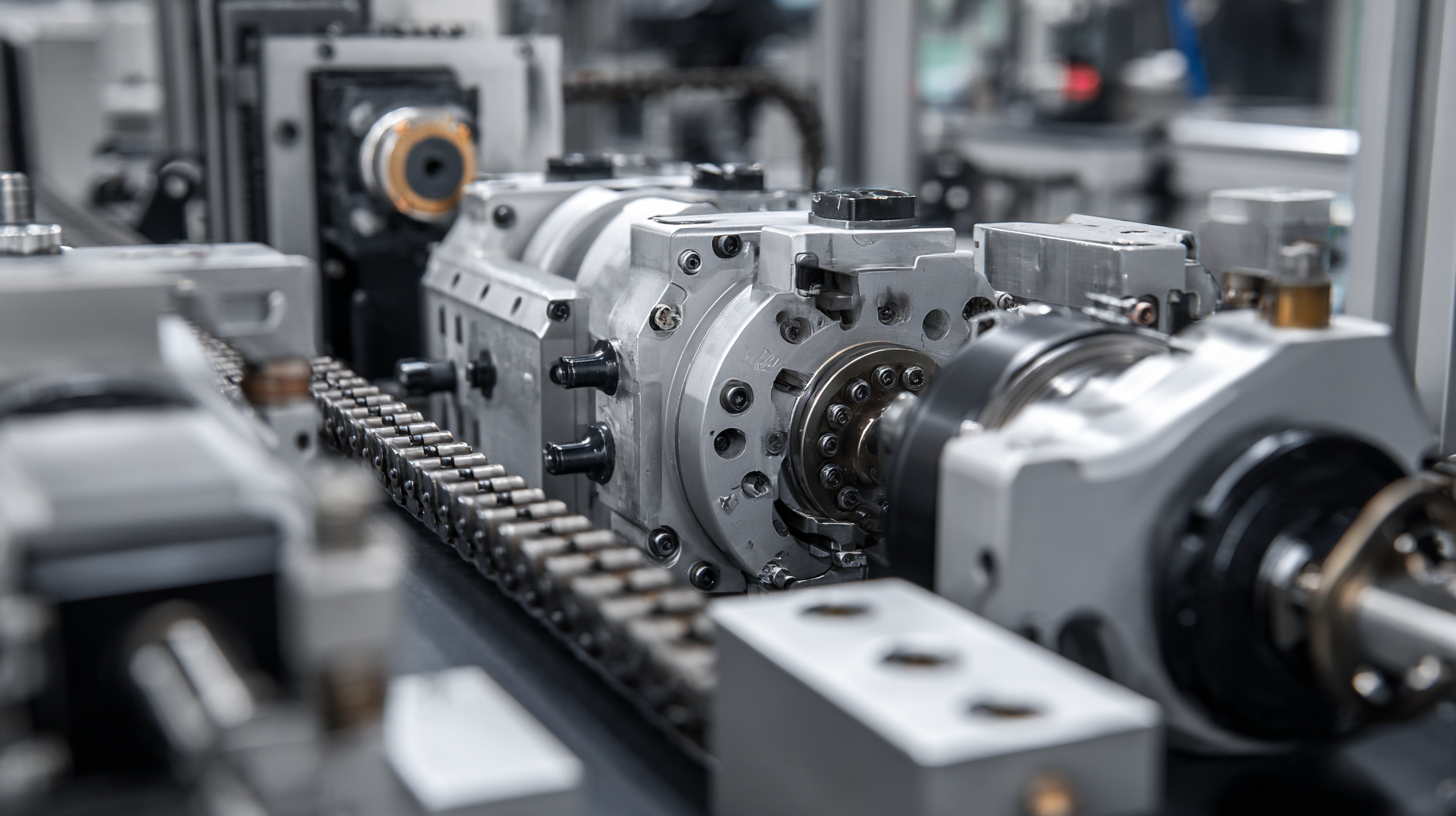

The ball chain coupling manufacturing industry is poised for significant transformation, driven by innovative technologies that are reshaping production processes globally. According to a report by MarketsandMarkets, the global coupling market is expected to reach USD 5.5 billion by 2026, growing at a CAGR of 4.3%. This growth is spurred by advancements in automation and smart manufacturing techniques, which enhance precision and reduce lead times in production.

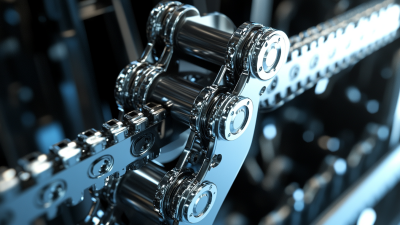

One of the key innovations in the field is the integration of IoT (Internet of Things) technologies, which enable real-time monitoring and predictive maintenance of ball chain coupling machines. A study by Allied Market Research indicates that the adoption of IoT in manufacturing can reduce operational costs by up to 15%, providing companies with a competitive edge in the market. Additionally, the implementation of AI and machine learning algorithms aids in optimizing production schedules, thereby maximizing output efficiency and minimizing downtime in the manufacturing process. As companies continue to embrace these technologies, the future of ball chain coupling production looks increasingly bright and automated.

| Technology | Description | Impact on Production | Expected Adoption Year |

|---|---|---|---|

| Automation | Integration of robotics and automated systems for assembly processes. | Increased efficiency, reduced labor costs, and enhanced precision. | 2025 |

| 3D Printing | Additive manufacturing techniques for producing complex components. | Lower material waste, customization opportunities, and faster prototyping. | 2024 |

| IoT Integration | Connecting machines to the internet for real-time data monitoring and analytics. | Enhanced machine efficiency, predictive maintenance, and improved quality control. | 2026 |

| Artificial Intelligence | Use of AI for optimizing production processes and quality assurance. | Improved decision-making, reduced downtime, and enhanced production agility. | 2027 |

| Sustainability Technologies | Innovative materials and processes that reduce environmental impact. | Meeting regulatory demands and improving brand reputation. | 2025 |

As the demand for eco-friendly production intensifies, the integration of sustainability practices in the manufacturing of ball chain coupling machines has become paramount. These machines, essential in various industries for their functionality and reliability, are now being designed and produced with a keen focus on minimizing environmental impact. Manufacturers are exploring innovative materials that not only enhance performance but are also recyclable and less harmful to the planet. This shift towards sustainable materials marks a significant step in reducing the carbon footprint associated with production processes.

In addition to material choices, energy-efficient manufacturing processes are being adopted, further contributing to eco-friendly practices. By optimizing machine operations and incorporating renewable energy sources, manufacturers can significantly decrease energy consumption. This progressive approach not only benefits the environment but also aligns with the growing consumer preference for sustainable products. Furthermore, implementing rigorous waste management strategies helps in reducing scrap during production, promoting a circular economy within the industry. Companies that embrace these sustainability practices stand to gain not only a competitive edge but also contribute to a greener future.

The ball chain coupling industry is poised for significant growth, yet it faces several challenges that could hinder its advancement. According to a recent report by ResearchAndMarkets, the global ball chain coupling market is expected to experience a CAGR of 4.2% over the next five years. One major challenge is the rising cost of raw materials, which has increased by approximately 15% since 2022. Manufacturers are struggling to maintain competitive pricing while ensuring quality, leading to calls for improved supply chain management practices and alternative sourcing strategies.

Another significant hurdle is technology integration. Many companies are still reliant on outdated machinery, which can result in inefficiencies and higher production costs. The World Manufacturing Forum reports that companies embracing automation and smart manufacturing solutions have seen productivity increases of up to 25%. By investing in state-of-the-art coupling machines and training employees to operate these advanced systems, businesses can overcome production bottlenecks and enhance overall efficiency.

Addressing these challenges is vital for the ball chain coupling industry to capitalize on emerging opportunities in global production.

In the rapidly evolving landscape of ball chain coupling manufacturing, strategic collaborations are essential for fostering global growth. Recent market research indicates that the ball chain coupling market is projected to grow at a CAGR of 5.1% from 2023 to 2030, driven by increasing demand across various sectors, including automotive and industrial machinery. Collaborations between manufacturers and technology providers can accelerate innovation and improve production efficiency, allowing companies to meet the rising demands of their clientele.

Tips for effective collaborations include aligning goals with partners early in the process. Setting clear, mutual objectives can improve resource allocation and streamline operations, fostering a more agile production environment. Additionally, leveraging the expertise of partners in areas such as automation and supply chain management can enhance the overall manufacturing process.

Another critical aspect is embracing digital transformation. By integrating advanced technologies like IoT and AI into production lines, companies can optimize their operations and reduce costs. This not only strengthens their market position but also opens avenues for new partnerships that capitalize on these technologies. As the industry continues to evolve, those who prioritize strategic collaborations will be best positioned to thrive in the global market.