In the rapidly evolving landscape of manufacturing, the Box Chain Making Machine stands at the forefront of innovation and technological advancement. As industries seek to enhance productivity, efficiency, and sustainability, the role of such machinery becomes increasingly vital. However, alongside these developments, various issues related to the functionality, maintenance, and adaptation of Box Chain Making Machines have emerged. This blog will explore the current problems faced in the operation and implementation of these machines, while also examining the innovations designed to address these challenges. From integrating smart technology to improving material handling processes, the future of Box Chain Making Machines looks promising. By navigating these intricacies, manufacturers can ensure that they not only keep pace with industry standards but also leverage cutting-edge advancements to enhance their production capabilities.

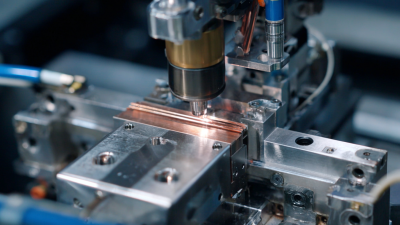

The evolution of box chain making machines in the digital age has ushered in a transformative phase in manufacturing processes. Traditional machines operated on manual settings and basic automation, limiting their efficiency and scalability. However, with the advent of advanced technologies such as IoT (Internet of Things) and AI (Artificial Intelligence), box chain making has become more sophisticated and streamlined. Modern machines are now equipped with smart sensors and programmable systems that allow for real-time monitoring and adjustments, significantly enhancing productivity and reducing downtime.

Moreover, digital advancements have paved the way for customization and precision in production. Manufacturers can now leverage data analytics to predict demand trends and optimize their output accordingly, ensuring a more agile response to market changes. Advanced software solutions also facilitate intricate designs and superior quality control, leading to a more robust end product. As the industry continues to embrace these innovations, the future of box chain making machines promises to be characterized by greater efficiency, sustainability, and a focus on meeting the evolving needs of consumers in an increasingly digital world.

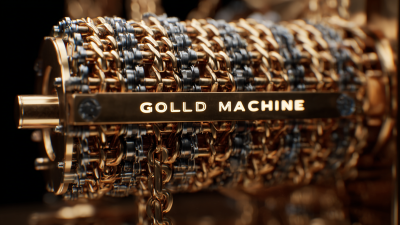

The manufacturing industry is experiencing a transformative shift driven by technological innovations, particularly in the realm of box chain making machines. Recent advancements in blockchain technology have emerged as a pivotal force in this evolution, streamlining production processes and enhancing data integrity. As industries increasingly adopt blockchain, manufacturers are finding new efficiencies through secure, decentralized systems that track every step of the production line. This not only improves transparency but also fosters trust among stakeholders.

At a recent conference, experts emphasized the critical role of core technologies like blockchain in promoting independent innovation within the manufacturing sector. With initiatives introduced by government bodies, there is a clear mandate to harness these technological advancements to boost industrial innovation. As manufacturers embrace these advancements, the integration of intelligent automation coupled with blockchain is expected to redefine the landscape of box chain manufacturing, paving the way for a more dynamic and interconnected industry. Furthermore, as companies strive to stay competitive in an evolving marketplace, investing in these technologies will be essential for sustaining growth and ensuring high-quality production standards.

The rapid evolution of automation technology is reshaping the landscape of box chain manufacturing, significantly enhancing production efficiency. According to a recent report by Fortune Business Insights, the global market for industrial automation is expected to reach $300 billion by 2026, growing at a CAGR of 9.5%. This shift is largely driven by the integration of advanced machinery, including automated box chain making machines that streamline operations and reduce manual labor.

Automation not only minimizes human error but also accelerates production cycles. Advanced machinery can operate continuously at high speeds, producing thousands of box chains per hour, which traditional methods struggle to match. For instance, data from the International Federation of Robotics indicates that manufacturers utilizing automated systems have observed up to a 30% increase in productivity. Furthermore, the implementation of real-time monitoring systems allows for immediate feedback and adjustments, optimizing resource allocation and reducing downtime. As these innovations continue to develop, the box chain industry is set to improve its efficiency and competitiveness in an increasingly automated world.

As the demand for sustainability in manufacturing grows, the box chain making machine industry is seeing significant innovations aimed at reducing environmental impact. Designers are now focusing on materials that are not only durable but also sustainable, such as recycled plastics and eco-friendly metals. These advancements not only help in minimizing waste but also improve the energy efficiency of the machines, leading to a reduced carbon footprint during production.

When adopting new sustainability trends, consider implementing a maintenance schedule for your machinery. Regular upkeep ensures that machines run efficiently, which can significantly lower energy consumption. Additionally, exploring upgrades for existing equipment can enhance operational performance while adhering to sustainable practices.

Another crucial aspect is to prioritize the use of energy-efficient components. By investing in machines that utilize less power or those that integrate renewable energy sources, businesses can achieve substantial cost savings in the long run. Furthermore, educating staff on sustainable practices is essential to foster a culture of environmental responsibility within the organization, ensuring that sustainability becomes a fundamental part of operational strategy.

The future of box chain making technology is set to experience transformative advancements driven by innovations in automation and blockchain integration. According to recent reports, the adoption of automated solutions is expected to increase productivity in manufacturing processes by up to 30% over the next decade, reducing operational costs and improving overall efficiency. This shift towards automation aligns with the larger trend of industry 4.0, where interconnected devices and intelligent systems create a more streamlined production environment.

Moreover, the introduction of blockchain technology into the supply chain management aspect of box chain manufacturing is promising to enhance transparency and traceability. As highlighted by the ongoing evolution in the blockchain sector, integrating decentralized systems could reduce fraud and improve tracking throughout the production lifecycle. Industry experts forecast that by 2025, around 60% of manufacturers will have implemented blockchain solutions, which will revolutionize how box chains are produced, tracked, and validated, thereby paving the way for greater industry trust and reliability. The future prospects for box chain making technology not only focus on improved manufacturing processes but also on aligning with the digital transformation trends that are reshaping various sectors globally.