In recent years, the global demand for high-quality Gold Buffing Machines has significantly surged, driven by the burgeoning jewelry and electronics industries. According to a report by Mordor Intelligence, the global metal finishing market, which encompasses buffing technologies, is projected to reach a valuation of approximately USD 12 billion by 2025, growing at a CAGR of over 8%. This boom underscores the necessity for manufacturers to prioritize quality, efficiency, and durability in their offerings. China's premier Gold Buffing Machines stand out in this competitive landscape, not only due to their superior craftsmanship but also because they offer exceptional after-sales service advantages and lower maintenance costs. As the industry evolves, the future of buffing technology is poised to integrate advanced automation and eco-friendly processes, ensuring that these machines meet the escalating expectations of both domestic and international markets.

In recent years, the global demand for high-quality Gold Buffing Machines has significantly surged, driven by the burgeoning jewelry and electronics industries. According to a report by Mordor Intelligence, the global metal finishing market, which encompasses buffing technologies, is projected to reach a valuation of approximately USD 12 billion by 2025, growing at a CAGR of over 8%. This boom underscores the necessity for manufacturers to prioritize quality, efficiency, and durability in their offerings. China's premier Gold Buffing Machines stand out in this competitive landscape, not only due to their superior craftsmanship but also because they offer exceptional after-sales service advantages and lower maintenance costs. As the industry evolves, the future of buffing technology is poised to integrate advanced automation and eco-friendly processes, ensuring that these machines meet the escalating expectations of both domestic and international markets.

China's gold buffing machines have seen a meteoric rise in popularity across global markets, driven by their unparalleled quality and innovation. As industries around the world continue to seek efficient and reliable machinery, China's offerings have become the preferred choice for businesses focusing on precision and durability. These machines not only enhance the quality of finished products but also significantly reduce processing times, making them invaluable assets in various sectors, from jewelry to electronics.

The burgeoning demand for Chinese gold buffing machines can be attributed to several factors. Firstly, advancements in technology have allowed manufacturers to produce machines that meet international standards while also providing cost-effective solutions. Additionally, the emphasis on quality control in China's manufacturing processes has ensured that these machines perform with exceptional reliability. As a result, businesses in countries such as the United States, Germany, and Japan are increasingly integrating these machines into their production lines, recognizing their ability to enhance productivity and maintain competitive advantages in the global marketplace.

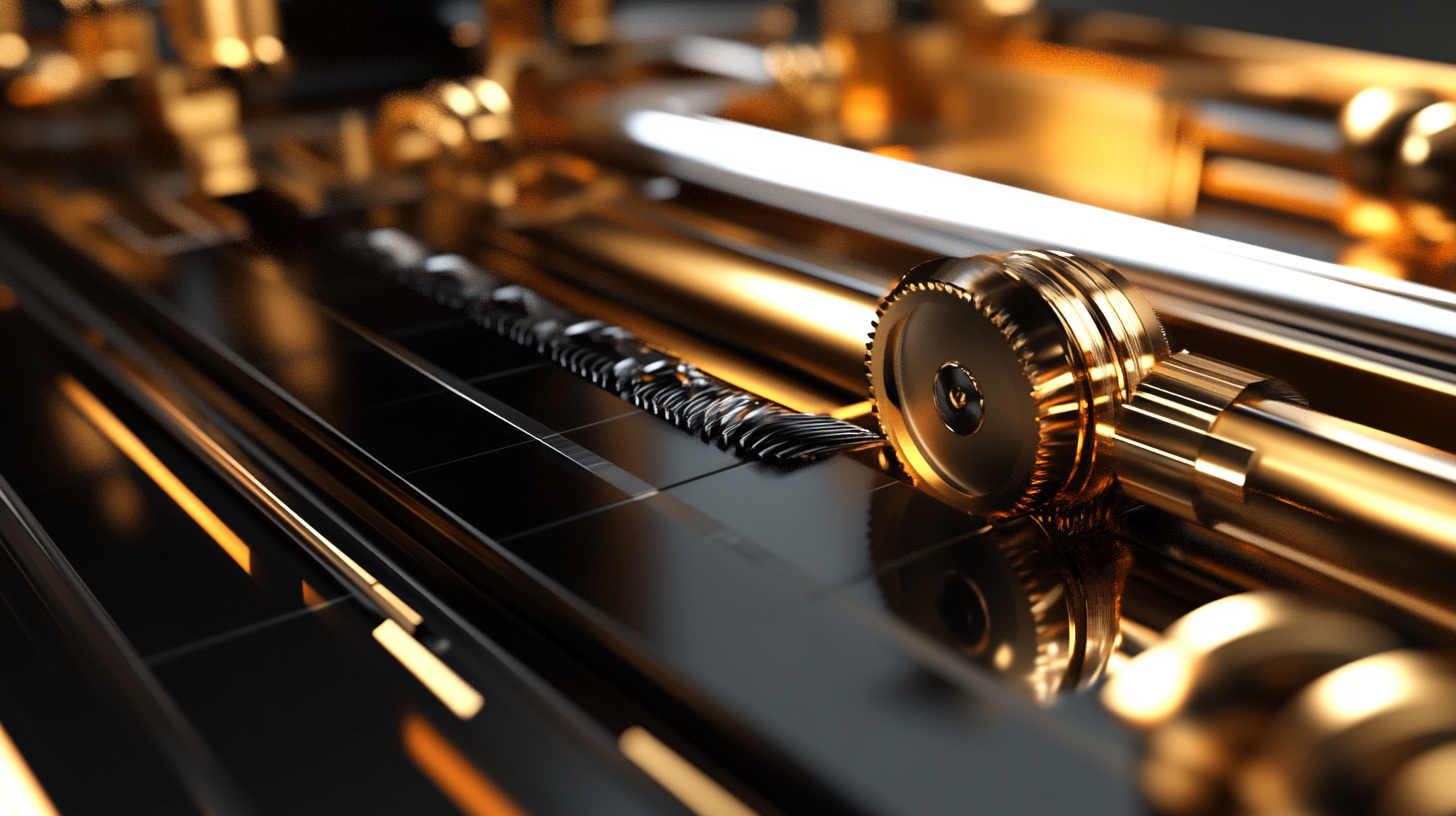

China has emerged as a dominant player in the manufacturing of gold buffing machines, setting a high bar for quality and innovation. When we compare Chinese machines to those from international competitors, several key differences become apparent. Chinese manufacturers utilize advanced technology and robust materials, resulting in machines that not only perform efficiently but also offer longevity. Their products exhibit precision in buffing, ensuring a perfect finish that is crucial for high-value gold pieces.

Furthermore, pricing plays a significant role in this comparative analysis. Chinese gold buffing machines are often more competitively priced than their international counterparts, making them an attractive option for businesses looking to balance quality and affordability. While some competitors may boast established reputations, the rapid advancements in Chinese manufacturing techniques, coupled with a strong focus on customer feedback and adaptability, enable them to meet global demands effectively. As businesses seek optimal solutions, the value proposition of Chinese machines becomes increasingly evident in the global market.

| Dimension | China’s Gold Buffing Machines | International Competitors |

|---|---|---|

| Average Price (USD) | $3,000 | $4,500 |

| Average Buffing Time (minutes) | 15 | 20 |

| Durability (Years) | 10 | 8 |

| Energy Consumption (kWh) | 2.5 | 3.5 |

| Warranty Period (Years) | 3 | 2 |

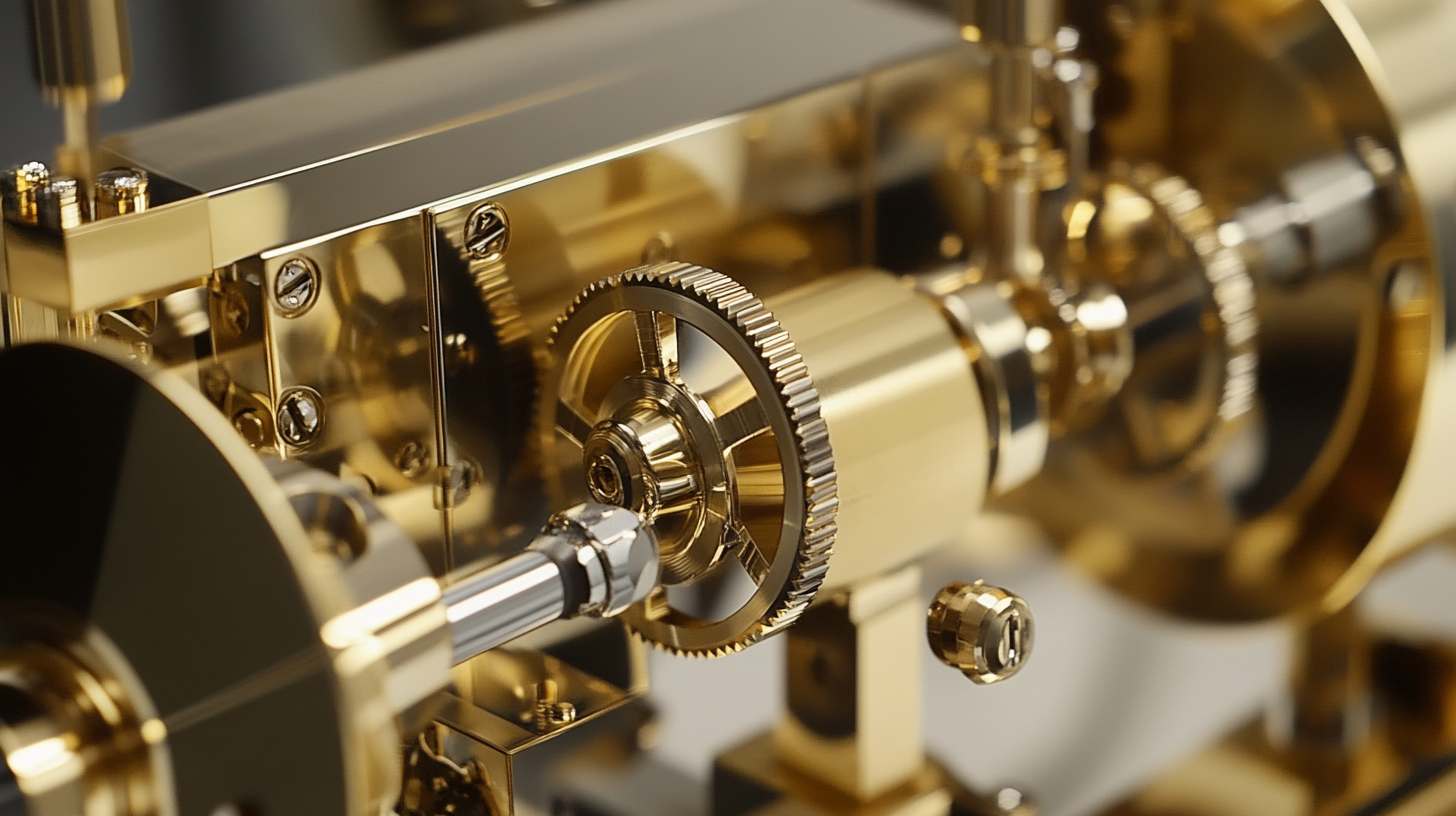

China has emerged as a leader in manufacturing advanced gold buffing machines, blending cutting-edge technology with innovative features to meet the demands of a global market. These machines are designed not only for efficiency but also for versatility, allowing jewelers and manufacturers to achieve a flawless finish on their gold products. The incorporation of automation technology streamlines the buffing process, ensuring consistency and reducing the time spent on manual labor.

One of the standout features of these buffing machines is their adaptability to different types of gold alloys, which is essential for businesses that work with a variety of materials. The user-friendly interfaces and programmable settings enable operators to customize buffing parameters according to specific requirements, enhancing both precision and output quality.

Additionally, these machines are equipped with safety features that protect operators while maintaining high productivity levels, making them an ideal investment for enterprises looking to elevate their crafting process while adhering to global safety standards.

In recent years, the focus on sustainability has transformed the manufacturing landscape, and Chinese buffing equipment is leading the charge with its green approach. Manufacturers are increasingly adopting eco-friendly technologies and practices that not only enhance efficiency but also reduce environmental impact. By utilizing advanced materials and energy-efficient processes, these machines are designed to operate with minimal waste, demonstrating a commitment to sustainability in every step of production.

Moreover, China's premier gold buffing machines are engineered for longevity and reliability, which contributes to a more sustainable lifecycle. By focusing on high-quality production and durable designs, these machines require less frequent replacement, thereby lowering resource consumption over time. This green philosophy aligns with global demand for environmentally responsible manufacturing solutions, positioning Chinese buffing machines as not only high performers but also responsible choices for businesses looking to balance productivity with ecological responsibility.

Customer testimonials shed light on the remarkable impact of China's premier gold buffing machines across various industries worldwide. Users consistently praise these machines for their durability and efficiency, noting significant improvements in their production processes. For instance, a jewelry manufacturer in Italy highlighted that after switching to a Chinese buffing machine, they were able to increase their output by 30%, while simultaneously enhancing the quality of their finishes. Such success stories showcase how global demand is met with top-of-the-line technology designed specifically for quality craftsmanship.

When selecting a gold buffing machine, consider the following tips to ensure optimal performance. First, assess the specific needs of your production line: different machines cater to various scales and types of work. Additionally, explore user reviews and testimonials to identify any common issues or standout features. Finally, do not underestimate the importance of after-sales support; an excellent warranty and service team can make all the difference in maintaining machine performance and longevity.

As more businesses share their experiences, it becomes clear that investing in high-quality Chinese gold buffing machines not only fulfills the demand for superior craftsmanship but also supports efficient production—helping businesses thrive on a global scale.