In the competitive landscape of textile manufacturing, the demand for high-quality weaving machinery has never been greater. According to recent market analyses, the global weaving machine market is projected to reach $12 billion by 2025, driven by advancements in technology and increased production capacity. Among the forefront of these innovations is the Chopin Chain Weaving Machine, renowned for its precision and efficiency. This state-of-the-art equipment, produced by China's leading manufacturing facilities, offers unparalleled performance, enabling global buyers to meet the growing demands of the industry. With features designed for both flexibility and durability, the Chopin Chain Weaving Machine is poised to elevate production standards, making it an essential investment for textile manufacturers seeking to enhance their competitive edge in an increasingly globalized market.

In recent years, China's Chopin chain weaving machines have made significant strides in global markets, driven by both technological advancements and increased demand for high-quality textile production. According to a report by ResearchAndMarkets, the global textile machinery market is projected to reach approximately $24.5 billion by 2025, with China accounting for a substantial share due to its robust manufacturing capabilities and innovation. The versatility of Chopin chain weaving technology allows manufacturers to produce intricate patterns and high-density fabrics, catering to diverse industry needs ranging from fashion to industrial textiles.

The rise of China's Chopin chain weaving machines can also be attributed to the nation's commitment to improving production efficiency and sustainability. A study published by Mordor Intelligence highlights that the demand for automatic and energy-efficient textile machinery is growing, with manufacturers seeking to reduce operational costs and environmental impact. This trend aligns perfectly with the features of advanced Chopin machines, which are designed to optimize energy consumption while delivering superior performance. As global buyers increasingly recognize the value of these technologies, China's position as a leader in the textile machinery sector is poised to strengthen even further.

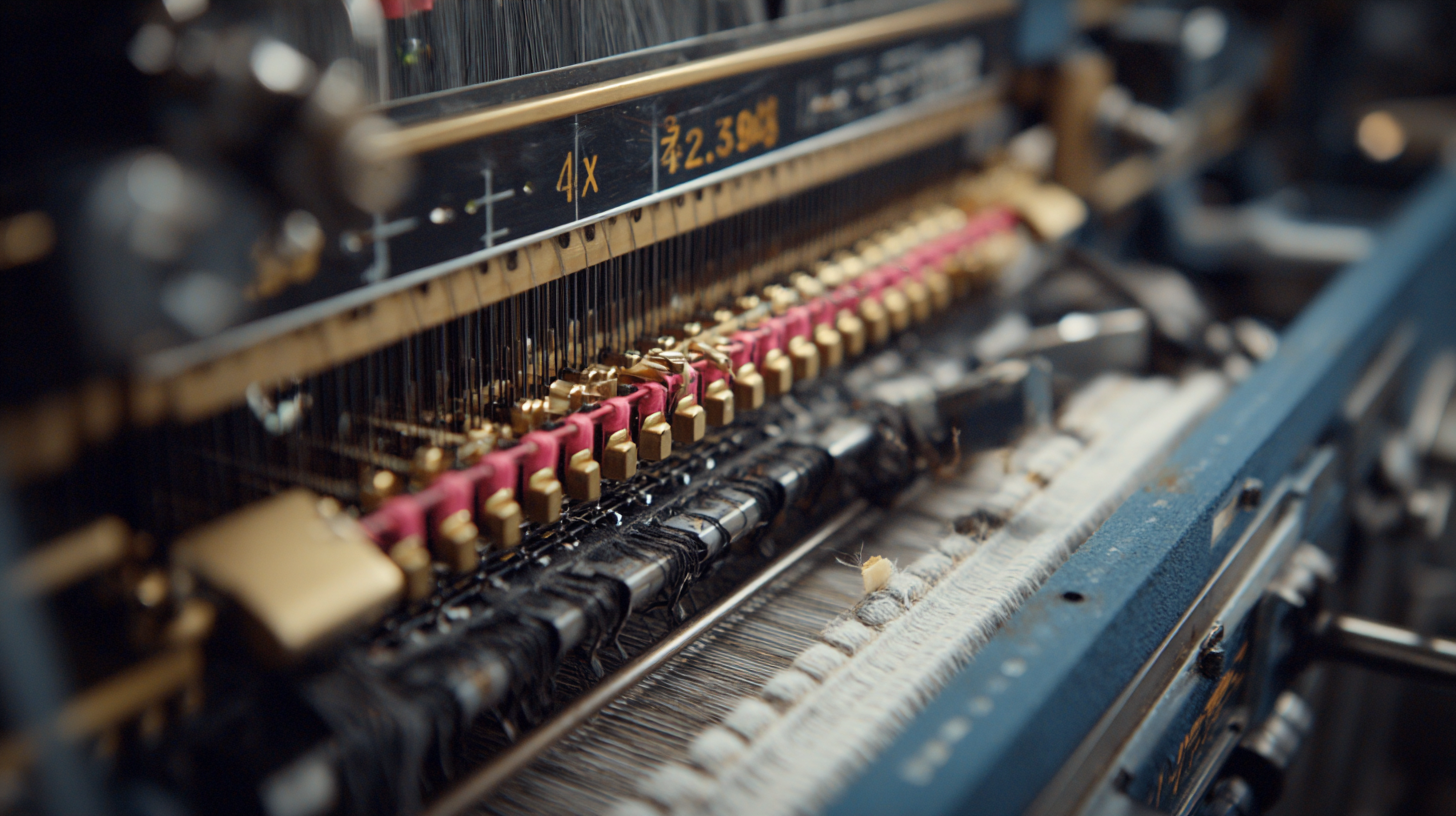

China has established itself as a powerhouse in textile machinery manufacturing, and its Chopin chain weaving machines stand out for their innovative features and reliable performance. According to a recent report by Research and Markets, the global weaving machine market is expected to reach $3.9 billion by 2025, driven by advancements in technology and rising demand for high-quality textiles. China's weaving machines, particularly the Chopin series, offer superior efficiency and versatility, incorporating advanced technologies such as automatic tension control and programmable digital interfaces, which significantly enhance production capabilities.

One of the key differentiators of China's weaving machines is their ability to adapt to various fiber types and weave patterns without sacrificing speed or quality. Data from the Textile Machinery Association indicates that machines with advanced settings can reduce production time by up to 30%, making them a preferred choice for manufacturers aiming to expedite time-to-market. Furthermore, the durability and low maintenance requirements of Chopin machines translate to lower overall operational costs, positioning them as a smart investment for global buyers looking to elevate their production standards.

| Feature | Description | Advantage |

|---|---|---|

| High Speed Operation | Can produce up to 1200 meters of fabric per hour. | Increases productivity and decreases manufacturing time. |

| Advanced Automation | Utilizes smart technology for easy operation and monitoring. | Reduces labor costs and enhances operational efficiency. |

| Energy Efficient | Designed to consume less power without compromising performance. | Lowers energy costs and supports sustainable practices. |

| High Precision Weaving | Ensures accurate yarn tension and weaving patterns. | Improves fabric quality and reduces waste. |

| Durability | Constructed with high-grade materials to withstand heavy use. | Minimizes maintenance costs and prolongs machine lifespan. |

The global demand for advanced weaving technologies is experiencing a significant surge, driven by the textile industry's need for efficiency and innovation. As manufacturers aim to meet the diverse preferences of consumers, the introduction of sophisticated machinery like the Chopin chain weaving machine is more critical than ever. This cutting-edge technology not only enhances productivity but also allows for the production of intricate designs and patterns that cater to modern fashion trends. As buyers across the globe seek reliable suppliers capable of meeting these demands, China's leading manufacturers have positioned themselves as key players in the market.

Furthermore, the rising awareness of sustainability in textile production is reshaping buyer requirements. Companies are now looking for weaving machines that minimize waste and energy consumption, reflecting a broader commitment to environmental stewardship. The Chopin chain weaving machine excels in this regard, featuring efficient operational capabilities that align with eco-friendly practices. This alignment of technology with consumer values is not only driving sales but also paving the way for future innovations in the weaving sector, reinforcing China’s status as a hub for advanced textile manufacturing solutions.

When it comes to producing high-quality weaving machinery, maintaining stringent quality control standards is paramount. In China, the production of chopin chain weaving machines is governed by a comprehensive set of quality protocols that ensure each unit meets international excellence benchmarks. These practices not only enhance the machines' performance but also contribute to the reliability and durability that global buyers seek.

Tip: When selecting a supplier, inquire about their quality control process. A reputable manufacturer will be transparent about their testing procedures and certifications. Look for companies that employ rigorous inspections throughout the production phase, as this can significantly affect the end product's quality.

Moreover, in the ever-evolving landscape of textile machinery, manufacturers are increasingly adopting advanced technologies to streamline their quality assurance efforts. By integrating automated testing systems and real-time monitoring, they can detect potential issues early in the production cycle. This proactive approach not only minimizes defects but also optimizes overall manufacturing efficiency.

Tip: Consider visiting the manufacturing facility if possible. Observing the production process firsthand can give you valuable insights into their quality control mechanisms and commitment to excellence. A manufacturer that prioritizes transparency is often dedicated to delivering top-notch products.

In the ever-evolving textile industry, the impact of innovative weaving solutions cannot be overstated.

The advent of advanced machinery, particularly the premier Chopin chain weaving machine from China,

has significantly enhanced production efficiency. This state-of-the-art equipment allows manufacturers to increase their output

while maintaining high standards of quality. The precision and speed of the Chopin machine streamline the weaving process,

enabling a smoother transition from raw materials to finished products. Consequently, companies are better positioned to meet

the growing global demand for textiles.

Moreover, the innovative features of these weaving solutions empower businesses to experiment with a broader range of fabrics

and designs. Enhanced versatility in production not only fosters creativity but also allows manufacturers to respond promptly

to market trends. By implementing modern technology, textile producers can achieve a more sustainable production model,

reducing waste and optimizing resource usage. This shift towards innovation not only elevates the capabilities of individual

manufacturers but also strengthens the global textile supply chain as a whole, leading to a more resilient and adaptable industry.