The art of jewelry making has undergone a significant transformation with the advent of advanced techniques such as electroforming. This innovative process allows for the creation of intricate designs that can captivate and inspire. According to renowned jewelry expert Dr. Elaine Rutherford, "The Electroforming Jewelry Machine is a game-changer in the industry, enabling artists to push the boundaries of their creativity while achieving remarkable detail." This statement emphasizes the profound impact that electroforming technology has on jewelry design.

Incorporating an Electroforming Jewelry Machine into the design process not only enhances the aesthetic appeal but also elevates the technical capabilities of artisans. The ability to electroform enables jewelers to produce lightweight pieces with the same structural integrity and detail as traditionally cast items. As designers continue to explore the possibilities, the electroforming technique reveals a world of stunning designs that can leave a lasting impression on the wearer.

In this exploration of top electroforming jewelry machine techniques, we will delve into the various methods and tips that can help both aspiring and established jewelers master this dynamic craft and unlock their full potential. With innovative technologies at their fingertips, the future of jewelry design is set to shine brighter than ever.

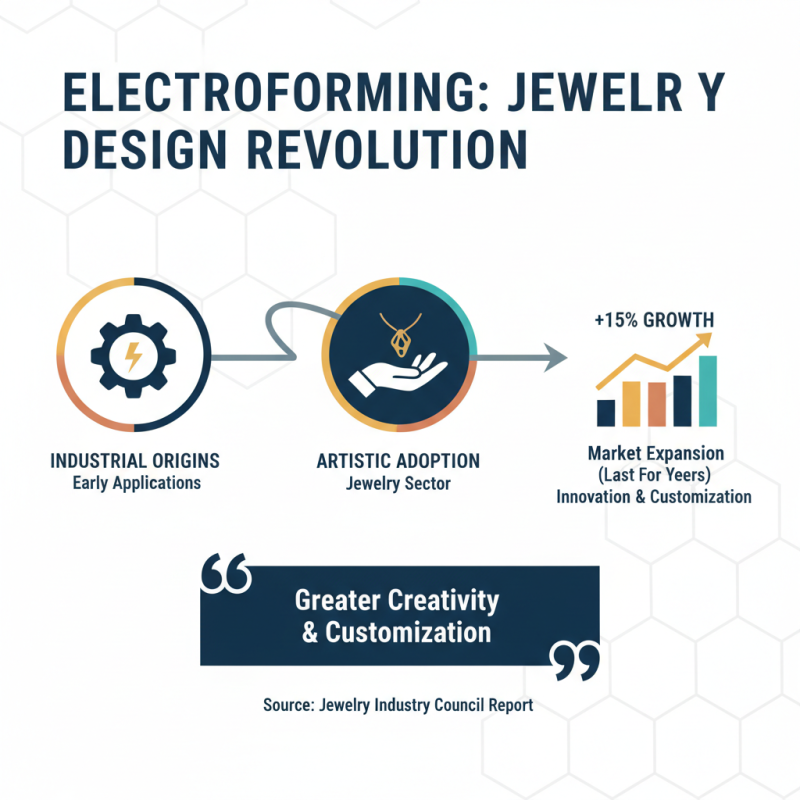

The evolution of electroforming techniques in jewelry design has transformed the way artisans create beautiful, intricate pieces. Initially, electroforming was primarily a process used in industrial applications, but its artistic potential was soon recognized, leading to its adoption within the jewelry sector. According to a report from the Jewelry Industry Council, the market for electroformed jewelry has grown by over 15% in the past five years, reflecting a significant shift towards innovative manufacturing methods that allow for greater creativity and customization.

Modern practitioners have leveraged advancements in technology to refine electroforming techniques, resulting in finer details and more complex designs. The introduction of more precise power supplies and specialized electrolytic solutions has enabled jewelers to achieve smoother surfaces and sharper details. A 2022 research study published in the Journal of Materials Science highlighted that the use of novel polymer-based mandrels is revolutionizing mold designs, allowing for easy removal and enhancing the overall durability of the electroformed pieces. This evolution not only increases the aesthetic appeal but also provides jewelers with the ability to create lightweight yet sturdy designs that cater to contemporary consumer preferences.

Furthermore, with the rise of eco-consciousness among consumers, sustainable practices in electroforming are becoming paramount. Many jewelers are now incorporating recycled metals into their processes, aligning with industry standards that underscore responsible sourcing. Reports indicate that more than 60% of customers now prioritize sustainable products in their purchasing decisions, prompting a shift in focus across the jewelry-making landscape. By embracing these evolving techniques, jewelers are not only enhancing their craftsmanship but also positioning themselves favorably in a competitive market that increasingly values sustainability and innovation.

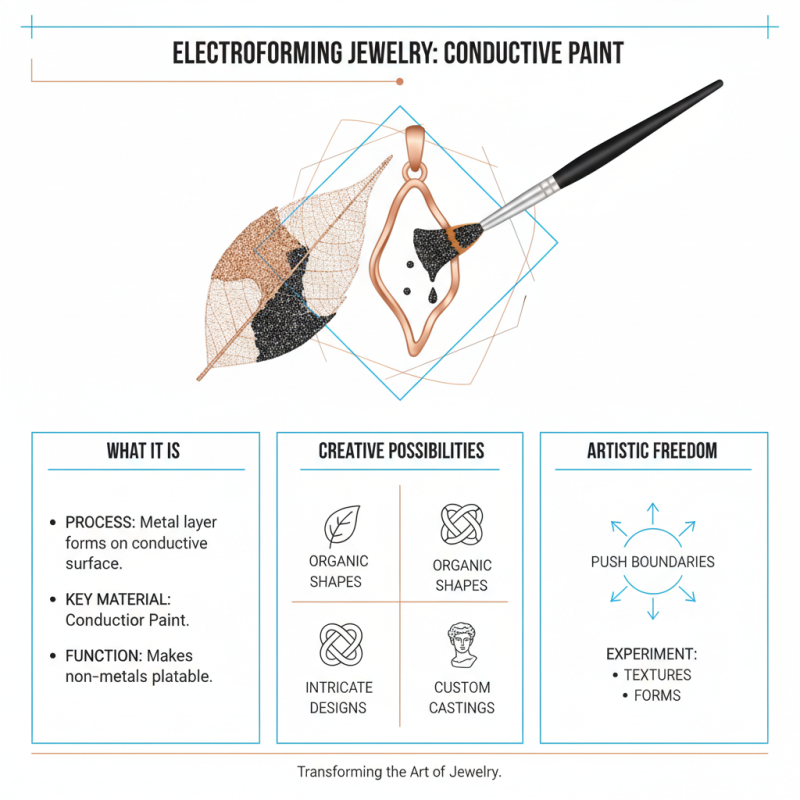

Electroforming is a transformative technique in jewelry creation that opens up a world of possibilities for artists and designers. One of the key materials used in this process is conductive paint, which allows non-conductive objects to be coated. This innovation enables a wide range of items—like organic shapes, intricate designs, or customized castings—to be enveloped in a layer of metal. The versatility of conductive paint expands the horizon of creativity, allowing jewelers to push boundaries and experiment with various textures and forms.

Another essential material in electroforming is the electrolyte solution, typically composed of copper salts and acids. This solution plays a crucial role in the electroforming process by facilitating the deposition of metal onto the designated surface. The thickness and quality of the electroformed layer can vary, depending on the concentration of these components as well as factors like current density and temperature. Jewels crafted from electroformed copper possess a unique aesthetic, combining a rugged industrial feel with delicate artistry, inspiring designers to create pieces that are both visually striking and finely detailed. These materials not only influence the final look of the jewelry but also contribute to its durability and functionality, making them indispensable in the electroforming process.

Electroforming and traditional goldsmithing stand as two distinct disciplines in the jewelry-making process, each offering unique advantages. Electroforming utilizes an electrochemical process to deposit metal onto a non-conductive mold, enabling artists to create intricate designs with unparalleled precision. A recent report from the Jewelry Industry Association highlights that electroforming can reduce production time by up to 40% compared to traditional methods, which often require extensive manual labor and craftsmanship. This efficiency allows for the rapid creation of complex and lightweight pieces, appealing to modern consumers seeking unique designs without compromising on quality.

On the other hand, traditional goldsmithing relies heavily on hand skills and craftsmanship, with artisans crafting pieces from solid metal. This method has been revered for centuries, yielding pieces characterized by durability and a personal touch that many customers appreciate. The National Jewelers Association reports that the craftsmanship involved in traditional methods can result in higher perceived value among customers, often leading to a willingness to pay a premium for hand-made jewelry. However, this approach can be labor-intensive, which may limit scalability for mass production.

Tips: When choosing between electroforming and traditional goldsmithing, consider your target market. If your customers prioritize unique, lightweight designs, electroforming may be the best fit. Alternatively, for markets that value traditional craftsmanship, emphasize the artistry and time invested in each piece made by hand. Additionally, stay abreast of advancements in technology and materials to optimize your design process and keep your creations ahead in a competitive market.

The electroformed jewelry market has been experiencing significant growth, driven by increasing consumer interest in unique and customizable designs. According to a recent industry report, the global market for electroformed jewelry is projected to expand at a compound annual growth rate (CAGR) of over 10% through the next five years. This surge is attributed to the rising demand for lightweight and intricately detailed pieces, as electroforming allows for the creation of complex shapes that would otherwise be challenging to produce with traditional jewelry-making methods.

Moreover, market analysts highlight that the customization trend, fueled by social media and influencer culture, has encouraged artisans and small businesses to adopt electroforming techniques. The process not only enables jewelers to explore innovative styles but also meets the consumer desire for personalized products. Data indicates that 65% of consumers are more likely to purchase jewelry that reflects their unique identity, prompting a shift towards services that offer bespoke options. As the technology behind electroforming continues to evolve, the potential for creative expression in jewelry design expands, making it an appealing avenue for both established brands and emerging designers.

Maintaining electroforming equipment is crucial for achieving optimal performance and prolonging the lifespan of the machinery. Regular cleaning is one of the best practices that cannot be overlooked. This involves removing any residue or build-up that can affect the conductivity and efficiency of the electroforming process. It’s important to use non-corrosive cleaning agents and follow the manufacturer’s guidelines to ensure the integrity of the components. Additionally, inspecting electrodes and other parts for wear and tear should be a routine procedure, as this can prevent unexpected downtimes and production delays.

Another essential aspect of maintaining electroforming equipment is monitoring the settings and conditions under which the machines operate. Keeping a close eye on parameters such as temperature, voltage, and solution concentration can significantly impact the quality of the electroformed jewelry. Regular calibration of the machinery ensures consistent results and minimizes the risk of defects in the finished pieces. Employees should be trained to recognize changes in performance and conduct routine checks on all components to ensure everything operates smoothly. This proactive approach not only enhances productivity but also fosters an environment conducive to creativity and innovation in jewelry design.

This bar chart illustrates the efficiency of various electroforming techniques used in jewelry making. The data represents the average time (in hours) taken to complete the electroforming process for different techniques. A more efficient technique results in a shorter time required to produce a stunning piece of jewelry.