The efficient operation of the Chopin Chain Weaving Machine is crucial for modern textile production. According to expert James Thornton, "Mastering this machine is key to maximizing productivity." This sentiment resonates with many in the industry who see the potential for efficiency gains.

Proper training and practice are essential. Operators must familiarize themselves with the machine’s intricacies. Misunderstandings in setup can lead to errors and wasted materials. Attention to detail during the weaving process is vital. Each adjustment can impact the final product significantly.

Challenges arise often. Operators might struggle with specific settings. Identifying these hurdles is the first step in improvement. Reflecting on these challenges promotes a culture of learning. Ultimately, refining the use of the Chopin Chain Weaving Machine fosters both personal and organizational growth.

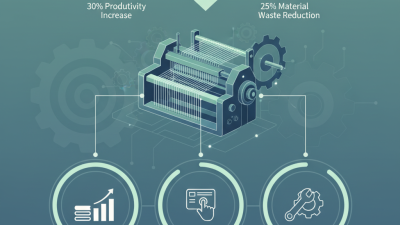

The Chopin Chain Weaving Machine is a remarkable tool in textile manufacturing. Understanding its fundamentals is crucial for effective operation. This machine upholds a weave efficiency rate of approximately 85%. However, many operators still struggle to reach this benchmark.

One common pitfall is improper setup. A significant percentage of users reported issues due to misalignment of the loom. This can lead to defects in the final product. According to industry surveys, nearly 30% of weaving errors stem from setup mistakes. Ensuring that the warp and weft threads are perfectly aligned is essential for optimal performance.

Regular maintenance also plays a pivotal role. Operators often overlook the importance of lubrication. Insufficient lubricant can lead to increased friction and wear. Its effects are twofold: reduced efficiency and heightened downtime. On average, machinery downtime can cost manufacturers 5% of operational efficiency. Therefore, it’s imperative that operators prioritize routine checks to maximize productivity.

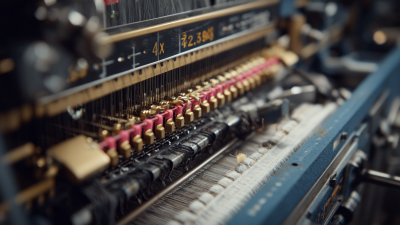

Setting up the Chopin chain weaving machine is crucial for optimal performance. Start by choosing a clean, dry workspace. Ensure all tools are within reach. Proper lighting can help prevent errors during setup. Check the machine for any signs of wear or damage. This can save time later.

Adjust the tension settings carefully. Proper tension ensures even weaving. Too tight can break the thread. Too loose may cause inconsistencies in the product. It’s important to calibrate this based on material types. Experimenting can lead to better results.

Next, thread the machine according to the guidelines. Mistakes at this stage can affect the entire process. Take time to double-check connections. Sometimes, it's easy to overlook small details. Finally, run a few test patterns before production. This helps identify any potential issues. Fine-tuning is often necessary. Expect some trial and error along the way.

Operating the Chopin Chain Weaving Machine efficiently requires attention to detail and strategic techniques. Proper setup is critical. Ensure the machine is well-lubricated and adjusted for the specific task. Small adjustments can make a significant difference. For instance, incorrect tension on the threads can lead to poor quality.

Tip: Always inspect the yarn before starting. Check for knots or imperfections. This step can save time later. Flawed material may cause disruptions during the weaving process. Have a plan for managing any discrepancies that arise.

Maintaining a steady pace is essential. Rushing can result in errors. Take breaks to avoid fatigue, as tiredness can diminish focus. Keep an eye on the fabric condition and thread tension throughout the operation. If you notice any issues, pause to correct them immediately.

Tip: Track your production speed. This practice helps identify areas for improvement. Reflect on your pace and efficiency regularly. Analyzing your approach aids in refining your skills over time, leading to better results.

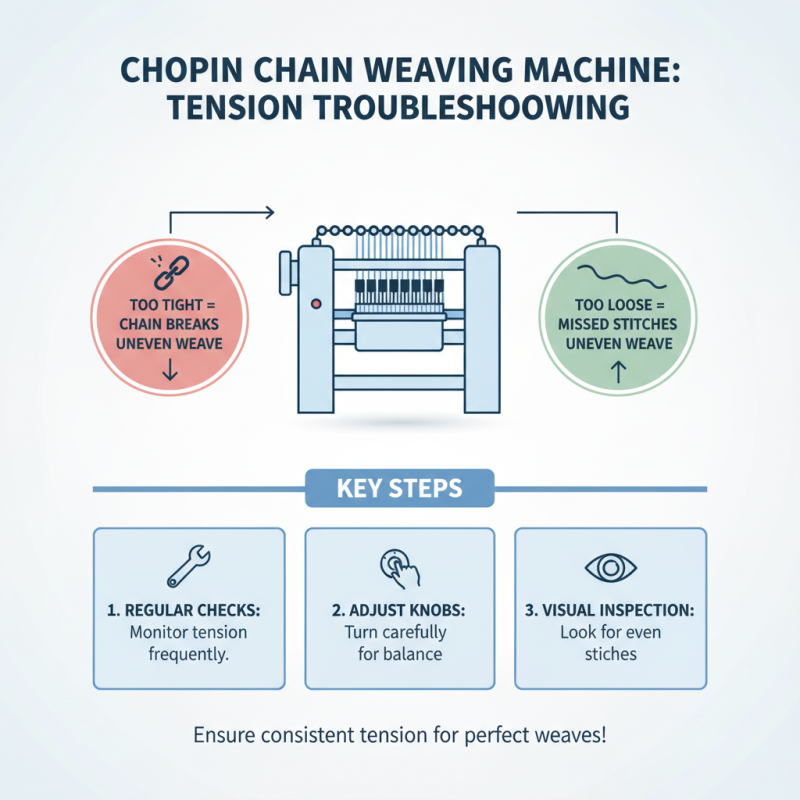

When operating the Chopin chain weaving machine, issues might occur unexpectedly. One common problem is inconsistent tension in the chain. This can lead to uneven weaving results. Check the tension settings regularly. Adjust the knobs carefully. A too-tight chain can break, while a loose chain causes missed stitches.

Another frequent concern is thread jamming. This often happens due to improper threading. Ensure the thread path is clear of obstacles. It’s helpful to run the machine slowly at first. Listen for unusual sounds. They might indicate an issue. If you notice a jam, stop immediately. Remove the blockage gently to avoid further damage.

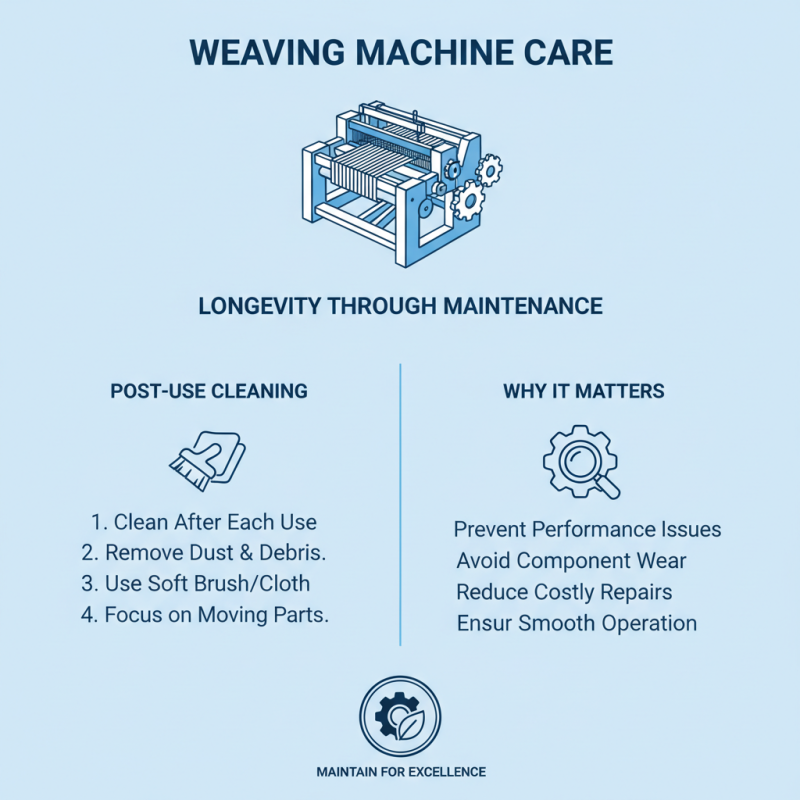

Keep the machine clean as well. Dust accumulation can affect performance. Wipe down the surfaces regularly. Inspect the moving parts for wear and tear. Sometimes, despite all precautions, parts wear out faster than expected. Reflect on your operational habits to identify any areas that need improvement. Making minor adjustments can improve efficiency significantly.

Regular maintenance is crucial for the longevity of the weaving machine. One effective practice is to clean the machine after each use. Dust and debris can accumulate and affect performance. Use a soft brush or cloth to remove any buildup from the machine’s components. Pay special attention to moving parts. A small oversight here can lead to significant issues.

Lubrication is another key task. Use the manufacturer’s recommended oils. This ensures all parts move smoothly. Remember, too much or too little lubricant can cause problems. Check the oil levels frequently. A well-lubricated machine operates more efficiently, reducing wear and tear. Don't rush this process; take your time to do it right.

Worn-out parts can disrupt operation. Inspect components regularly for signs of wear. Replace any parts that appear damaged or old. This proactive measure can prevent larger issues down the road. Sometimes, repairs take longer than expected. Be prepared for occasional downtime and plan maintenance schedules accordingly. A little effort goes a long way in maintaining functionality.