Jewelry making has evolved into a popular and creative outlet, with the global market for handmade jewelry projected to reach approximately $53 billion by 2025, according to recent industry reports. Central to this craftsmanship is the effective use of a Basic Jewelry Soldering Kit, which equips artisans with the essential tools to join metal pieces seamlessly. Mastering soldering techniques can greatly enhance the quality and durability of jewelry creations, allowing artists to explore innovative designs while maintaining structural integrity. As more enthusiasts venture into jewelry making, understanding how to leverage a Basic Jewelry Soldering Kit becomes crucial for producing stunning pieces that stand out in a competitive marketplace, where unique craftsmanship is highly valued.

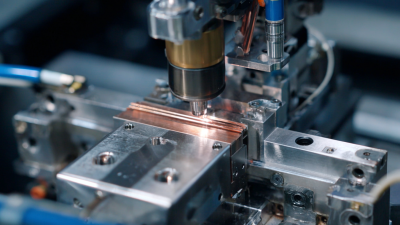

When embarking on your jewelry-making journey, having a well-equipped basic soldering kit is essential for achieving perfect joints in your creations. The key tools in this kit include a soldering iron, a flux applicator, and solder itself. The soldering iron is the heart of your kit; it provides the heat necessary to melt the solder and join pieces together. Selecting the right wattage for your iron can significantly impact your soldering quality.

In addition to the iron, a flux applicator is crucial for cleaning the metal surfaces before soldering. Flux not only prevents oxidation but also improves the flow of solder, making it easier to form strong joints. Finally, various types of solder are available, each suited for different metals and projects. Choosing the right solder, whether it's hard or easy solder, can make a world of difference in the durability and finish of your jewelry. By mastering these essential tools, you can elevate your jewelry-making skills to create stunning and professional-looking pieces.

When diving into jewelry soldering, understanding the different types of solder available is essential for achieving stunning results. Solder comes in various compositions, designed to work with particular metals such as gold, silver, or copper. Each type not only impacts the way the jeweler can manipulate the metal but also plays a crucial role in the final appearance of the piece. It's important to choose the right solder to match the metal you are working with, as this ensures the strength and integrity of the joint after cooling.

In addition to selecting the appropriate solder, the tools employed in the process can significantly influence the outcome of your jewelry creations. A high-quality soldering iron allows for precise heat control, essential for delicate work and detailed designs. Those looking to enhance their soldering experience will benefit from versatile tools, which can adjust to various soldering techniques and metal types. Mastering these elements will not only improve the quality of your jewelry but also expand your creative possibilities.

| Metal Type | Solder Type | Melting Point (°F) | Applications | Technique |

|---|---|---|---|---|

| Silver | Easy Solder | 1270 | General repairs, small joints | Patchwork soldering |

| Gold | Hard Solder | 1450 | High-strength joints, complex designs | Sweat soldering |

| Copper | Copper Solder | 1980 | Copper jewelry, sculptures | Welding and brazing |

| Brass | Lemon Solder | 710 | Cost-effective projects, repairs | Torch or soldering iron |

| Steel | Silver Solder | 1400 | Jewelry, metalwork | Fillet soldering |

When engaging in jewelry soldering, safety should be your top priority. Start by ensuring that your workspace is well-ventilated to prevent the build-up of harmful fumes from the soldering process. Utilizing a fume extractor or working near an open window can significantly reduce inhalation risks associated with soldering materials. Additionally, it is crucial to wear personal protective equipment; safety goggles will shield your eyes from solder splashes, while heat-resistant gloves will protect your hands from burns.

Your clothing should also reflect your commitment to safety—loose fabrics can easily catch fire, so opt for snug-fitting clothing made from materials that are less flammable. Moreover, keep a fire extinguisher nearby, just in case. It's advisable to have a first-aid kit on hand to address any minor injuries that might occur while working. By taking these precautions seriously, you can enjoy the creative process of soldering jewelry while minimizing risks to ensure your safety and well-being.

When venturing into the world of jewelry making, mastering soldering techniques is crucial to creating stunning pieces that stand out. The process begins with meticulous preparation, which includes selecting the right materials and setting up your workspace efficiently. According to a report by the Jewelry Industry Research Institute, nearly 60% of jewelry makers attribute their success to a well-organized workspace, highlighting the importance of environment in the crafting process. Proper safety measures, such as wearing goggles and ensuring adequate ventilation, are essential to protect yourself while soldering.

Once your workspace is ready, the next step is to practice basic soldering techniques. Begin by learning to heat your soldering iron to the appropriate temperature, ideally around 350-400 degrees Celsius, for effective melting without damaging the surrounding metal. The American Jewelry Design Council notes that 75% of jewelry-making errors can be traced back to improper soldering techniques, emphasizing the need for skillful execution. Finally, the finishing touches—such as cleaning, polishing, and adding patinas—transform your soldered pieces into professional-quality jewelry. A comprehensive survey revealed that 80% of consumers prefer buying jewelry that showcases intricate craftsmanship, which means honing your soldering skills can significantly enhance your marketability as a jewelry designer.

Soldering is a fundamental skill in jewelry making, but common mistakes can significantly hinder achieving professional results. One prevalent error is overheating the metals, which can lead to warping or melting. To prevent this, it's crucial to control the heat precisely and select the appropriate solder for the metal type being worked with. Utilizing a heat sink can also help dissipate excess heat and protect delicate components during the soldering process.

Another frequent mistake is inadequate cleaning of the surfaces to be joined. Oxides and dirt can prevent a proper bond, resulting in weak solder joints that are prone to breakage. Always ensure that the metal surfaces are meticulously cleaned with a file or sandpaper, followed by a quick dip in pickle solution to remove any contaminants. Additionally, using flux is essential as it helps to prevent oxidation during the heating process and promotes a clean bond. By avoiding these common pitfalls and focusing on precision and preparation, you can achieve stunning results in your jewelry creations.