In the dynamic world of jewelry manufacturing, choosing the right equipment can significantly influence the quality and efficiency of your production. One of the most vital machines in this realm is the Gold Chain Machine, which plays a critical role in the creation of exquisite gold chains that are both durable and attractive. As the demand for personalized and unique jewelry designs continues to rise, it becomes increasingly important for jewelry businesses to make informed decisions about the machinery they invest in.

Selecting the best Gold Chain Machine requires careful consideration of various factors, including production capacity, ease of use, and the machine's ability to produce intricate designs. Each of these elements can impact not only the quality of the final product but also the overall productivity of your operation. The right machine will not only streamline your production process but also enhance the craftsmanship of your gold chains, allowing your business to thrive in a competitive market.

In this guide, we will explore the essential features to look for when choosing a Gold Chain Machine, provide insights into the latest technological advancements, and share tips on how to make the best investment for your jewelry business. By understanding these critical components, you can ensure that your equipment meets your specific needs and elevates your brand in the jewelry industry.

When selecting a gold chain machine for your jewelry business, it is crucial to first assess your specific production needs. According to a recent industry report by IBISWorld, the jewelry manufacturing sector has seen a steady growth rate of approximately 3.1% annually. This indicates a rising demand for customized jewelry, which in turn necessitates an understanding of the types of chains that resonate with your target market. Evaluate the preferences of your customers regarding styles, lengths, and finishes to ensure that the machine you choose is capable of producing the desired chain types efficiently.

One important consideration is the scale of production. If your business focuses on custom, low-volume orders, a versatile machine that can handle various designs may be more beneficial. In contrast, for businesses focusing on higher volume production, investing in automated systems with faster output and fewer manual interventions could lead to better profitability. According to the Manufacturing Institute, automating production processes can increase productivity by up to 20%, allowing for lower labor costs and quicker turnaround times.

Tips: Before making a purchase, it is advisable to conduct a cost-benefit analysis that takes into account maintenance costs and training for your staff. Additionally, seek feedback from industry peers or professionals about the machine’s reliability and efficiency for specific production needs. This will help you make an informed decision that aligns with your business objectives and enhances your production capacity effectively.

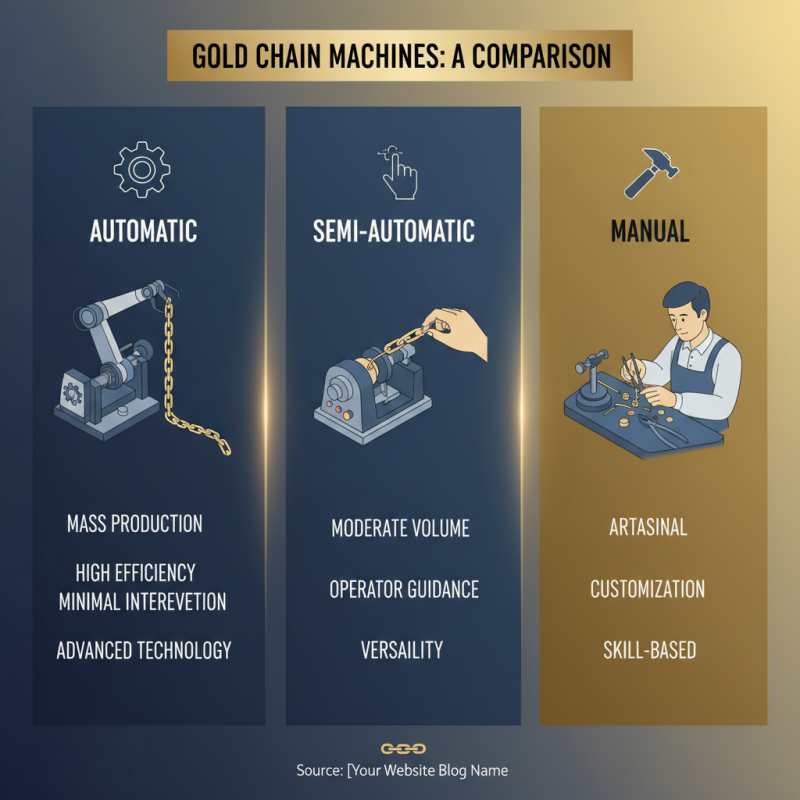

When selecting the best gold chain machine for your jewelry business, it's important to understand the various types available and their distinct features. The three primary types of gold chain machines include automatic, semi-automatic, and manual machines. Automatic machines are highly efficient and designed for mass production, allowing jewelers to create uniform chains quickly with minimal operator intervention. These machines often come equipped with advanced technology that enhances precision and reduces manufacturing time, making them ideal for larger operations focused on high-volume output.

Semi-automatic machines offer a balance between manual control and automation. They require some operator input while still providing mechanized assistance for specific tasks, such as linking or cutting chains. This type is suitable for businesses that may not require high output but still demand consistent quality and efficiency. Manual machines, while the most labor-intensive, offer jewelers greater control and flexibility in their designs. Ideal for custom or bespoke chain work, these machines allow artisans to fine-tune every aspect of the chain-making process, resulting in unique pieces tailored to customer specifications. Each type of machine has its strengths, and understanding these can help you choose the right one based on your business size, production goals, and the level of craftsmanship desired.

When selecting a gold chain machine for your jewelry business, there are several key specifications to keep in mind that can significantly impact your production efficiency and the quality of your output. First and foremost, consider the machine’s size and weight capacity. A robust machine is essential if you plan to produce heavy chains, while a compact model may be more suitable for lighter, intricate designs. Additionally, pay attention to the machine’s production speed, as faster machines can help meet high demand and increase your overall productivity.

Another crucial factor to evaluate is the machine's versatility. Look for features that allow for the creation of various chain styles and patterns, as this flexibility can cater to diverse customer preferences and expand your market reach. Moreover, ease of use and maintenance should also be considered. A machine that's user-friendly will facilitate training your staff and reduce operational errors, while easy maintenance features will minimize downtime and prolong the machine’s lifespan. Investing time in understanding these specifications will set your jewelry business on the path to success.

When budgeting for a gold chain machine purchase, it's crucial to consider both the immediate costs and the long-term investment potential. According to a recent industry report, the global demand for gold jewelry has been steadily increasing, with a projected market growth rate of approximately 6% annually through 2025. This surge suggests that investing in quality machinery can significantly enhance productivity and meet the growing demands of customers, leading to a better return on investment.

Initial costs for gold chain machines can vary widely depending on their features and capabilities. Entry-level machines might range from $5,000 to $15,000, while more advanced models can exceed $50,000. A detailed cost-benefit analysis is essential; consider aspects such as the machine's efficiency, the speed of production, and the volume of output to justify the expense. Furthermore, it is advisable to factor in additional costs such as maintenance, training, and the necessary materials, which can influence overall budgeting and operational costs. According to research, businesses that allocate 10-15% of their budget for machinery upgrades not only optimize their production capacity but also enhance the quality of their output, leading to increased sales and customer satisfaction.

Maintenance is crucial for ensuring the optimal performance of a gold chain machine in your jewelry business. Regular checks and servicing will help identify any potential issues before they escalate into significant problems. Cleaning the machine, lubricating moving parts, and ensuring that all components are functioning correctly can prevent unnecessary downtime and extend the life of the machine. Establishing a routine maintenance schedule can be beneficial, allowing for consistent performance while minimizing interruptions in production.

Support is equally important when it comes to maximizing the efficiency of your gold chain machine. Having access to knowledgeable technical support can be invaluable when faced with operational challenges or questions about machine settings. Consider investing in training for your team to ensure they understand both the functionality of the machine and its maintenance requirements. This investment not only enhances productivity but also empowers your staff to troubleshoot minor issues, ensuring that minor setbacks do not disrupt the overall workflow of your jewelry business.