When selecting the right Gold Chain Machine for your business, the stakes are high. According to jewelry expert Mark Thompson, "The right equipment can elevate your production and quality." This sentiment echoes the importance of making informed decisions.

Choosing a Gold Chain Machine requires careful consideration of various factors. The machine should meet your production needs while reflecting the quality standards of your brand. Each option presents unique features, which may confuse some business owners.

Potential buyers often feel overwhelmed. They must consider machine speed, durability, and cost efficiency. A wise purchase can solidify a brand’s reputation, while a poor choice harms productivity. Aim for a balance that suits your specific requirements, and don’t shy away from seeking expert opinions. Remember, investing time in research can prove invaluable in the long run.

When exploring the market for gold chain machines, it’s crucial to understand the different types available.

Wire drawing machines are common. They draw metal into finer strands. These are vital for making intricate gold chains.

Rolling mills are another option. They flatten gold sheets into desired thicknesses. Both machines serve unique purposes and are suited for different styles.

Tips: Consider your production needs. What type of gold chains do you plan to offer? Evaluate your output requirements. Production speed varies widely among machines. Some may struggle with heavy-duty tasks. Others might be ideal for small-scale production.

Another type is chain-making machines. These specialize in assembling links. They can produce various chain styles, from classic to modern. Keep in mind that not all chain machines handle all metal types well. Some might need adjustments for different gold alloys.

Tips: Always examine the machine’s specifications. Don’t overlook the importance of durability. A cheaper machine may seem appealing at first. However, it could lead to frequent repairs. Think carefully about your choice. Each machine type presents its own set of challenges and advantages.

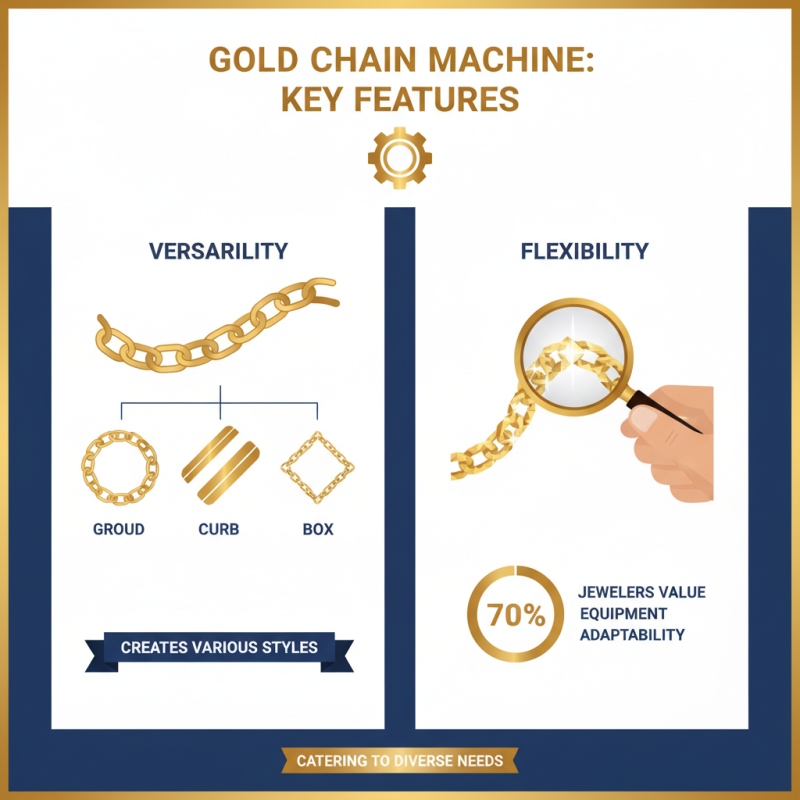

When selecting a gold chain machine, several key features are crucial. The machine's versatility stands out. A good model should create different chain styles. These include rolo, curb, and box chains. Versatile machines cater to diverse customer needs. According to industry reports, 70% of jewelers value flexibility in their equipment.

Another important feature is ease of use. An intuitive interface can greatly affect productivity. Operators should quickly learn how to use the machine. Complicated designs often lead to frustration. A report from the Jewelry Manufacturers Association indicates that up to 50% of machines are underutilized due to operator errors.

Durability is often overlooked. Many assume all machines will last. In fact, about 40% of gold chain machines fail within five years. Investing in robust machinery saves long-term costs. Regular maintenance and durability testing can aid in avoiding pitfalls. Finally, customer support can influence your decision. Machines can malfunction. Having reliable support is essential for business continuity.

When choosing a gold chain machine, analyzing production capacity is crucial. Your production capacity dictates how much gold chain you can create in a given timeframe. This directly impacts your ability to meet customer demands and optimize profit margins.

Consider the machine's speed and efficiency. A faster machine may seem attractive, but it can introduce quality issues. You need to balance speed with craftsmanship. Additionally, think about the working hours. Can the machine operate continuously without overheating? This may affect both production and maintenance schedules.

Evaluate your business needs. How many chains do you want to produce daily? Is your market demanding more styles or sizes? These questions guide your choice. Choosing a machine that meets specific production needs can prevent waste and lower costs. Reflect on your goals and ensure the machine aligns with them. Pay attention to any inconsistencies during testing. Such observations can reveal the machine's true performance before making a commitment.

| Machine Type | Production Capacity (grams/hour) | Material Compatibility | Power Consumption (kW) | Cost (USD) |

|---|---|---|---|---|

| Automatic Gold Chain Machine | 100-150 | Gold, Silver | 5 | 8000 |

| Semi-Automatic Chain Making Machine | 50-100 | Gold, Platinum | 3 | 5000 |

| Manual Gold Chain Machine | 20-40 | Gold | 2 | 2000 |

| Chain Welding Machine | 75-120 | Gold, Silver, Copper | 4 | 6000 |

When investing in a gold chain machine, cost-effectiveness is crucial. You need to assess not just the initial purchase price but also ongoing operational costs. Energy efficiency, maintenance needs, and potential labor costs should all be considered. A more expensive machine may save money over time.

Return on investment (ROI) is another important factor. Calculate how quickly the machine can pay for itself through increased production. Look at how much gold you can process in a day. A more efficient machine might allow you to produce more chains in less time.

However, you must remain cautious. The most advanced machine may not always be the best fit for your operation. Consider your business scale and production volume. Read reviews and seek feedback from other users. Learning from their experiences can help avoid costly mistakes.

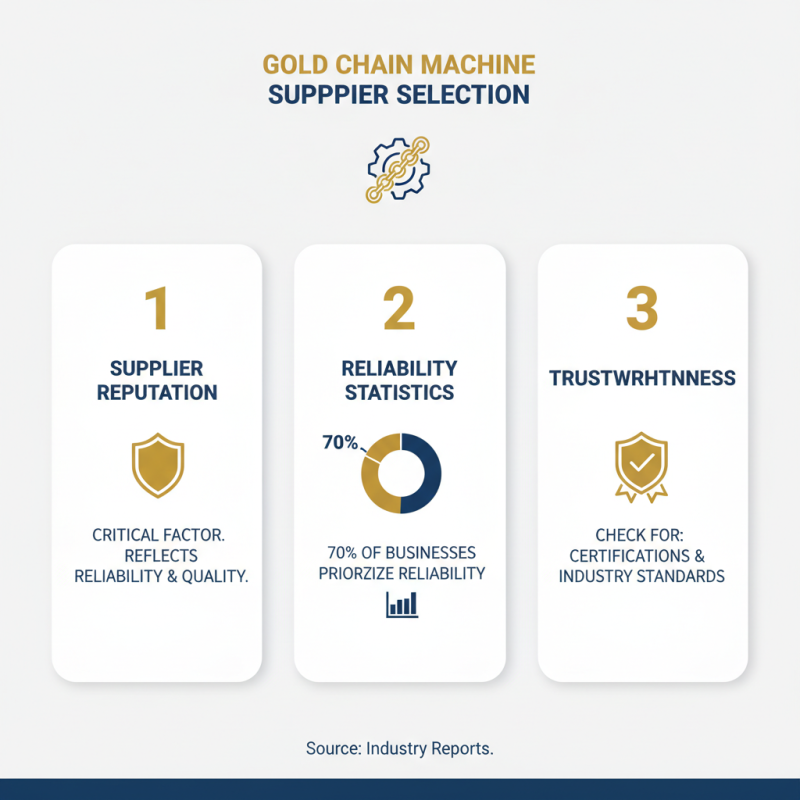

When selecting a gold chain machine for your business, supplier reputation stands as a critical factor. An established supplier often reflects reliability in quality and service. According to industry reports, around 70% of businesses consider supplier reliability as the most important criterion. Checking for certifications and industry standards can provide insights into a supplier's trustworthiness.

After-sales support is another vital aspect. A machine may operate flawlessly initially, but ongoing support is crucial. Consider whether the supplier offers training, maintenance, and timely repairs. Studies show that companies with strong after-sales support see an increase in customer satisfaction by up to 40%. Without this, businesses may falter when issues arise.

Tips: Always request references from current users. Their experiences can offer a deeper understanding of the supplier's true capabilities. Don't overlook reviews; they reveal potential red flags. Also, evaluate the supplier’s commitment to innovation. A lack of updates may indicate stagnant technologies, which can affect your production quality.

In the gold chain industry, every detail counts. Supplier reputation and solid after-sales support can influence your machine's performance and longevity. Reflect on these aspects seriously; the consequences of poor choices can be significant, leading to production downtime and financial loss.