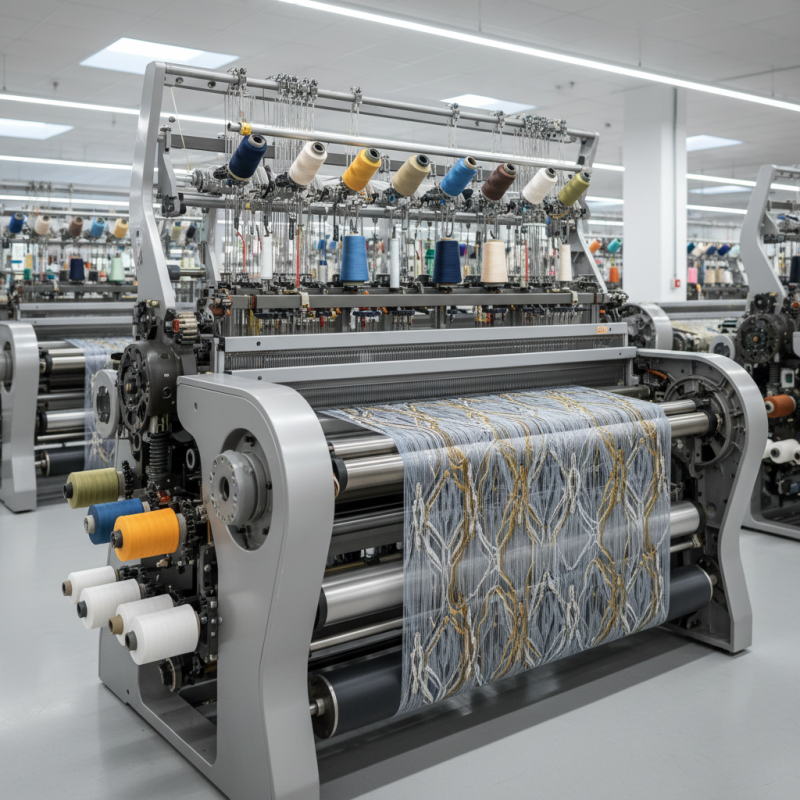

The evolution of textile machinery has greatly influenced the efficiency and quality of fabric production, and the Chopin Chain Weaving Machine stands out as a prominent choice among manufacturers. According to a recent report by Technavio, the global textile machinery market is projected to grow by USD 4.32 billion from 2020 to 2024, highlighting the increasing demand for advanced equipment that enhances productivity and supports innovative weaving techniques. With a focus on ergonomic design and technological integration, the Chopin Chain Weaving Machine is designed to meet the diverse needs of modern textile operations.

Selecting the ideal Chopin Chain Weaving Machine involves understanding specific production requirements, including material compatibility and output capacity. Industry data indicates that approximately 70% of textile manufacturers prioritize versatility and ease of maintenance when choosing weaving equipment, underscoring the significance of selecting the right machinery to optimize production processes. By effectively leveraging the features and capabilities of the Chopin Chain Weaving Machine, businesses can not only enhance operational efficiency but also expand their creative possibilities in fabric design and production.

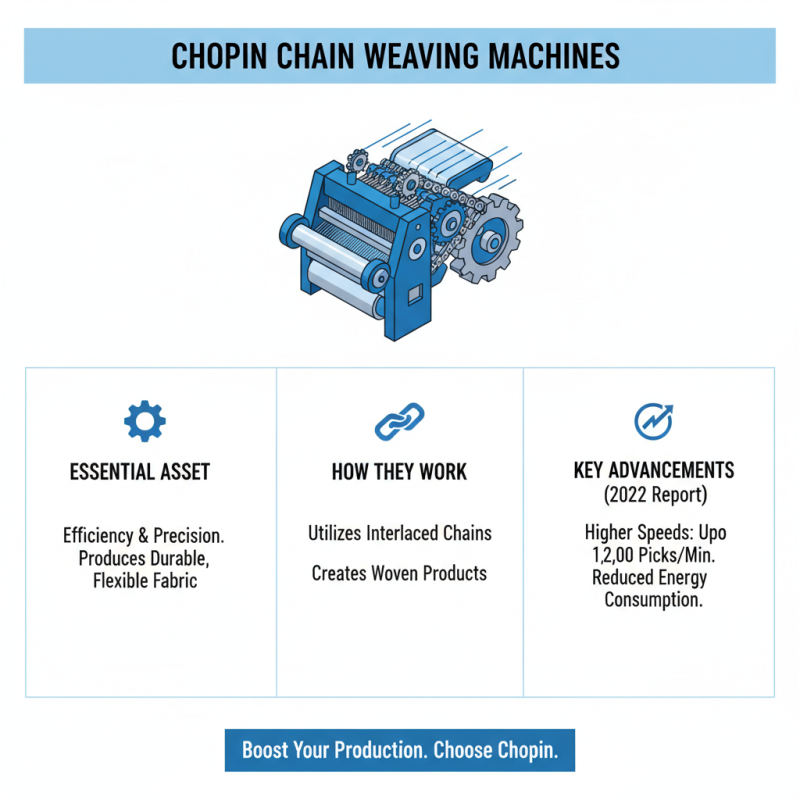

Chopin chain weaving machines are an essential asset for textiles manufacturers, providing efficiency and precision in producing woven products. Understanding the basics of these machines is crucial for selecting the best option for your needs. These machines use interlaced chains to create durable and flexible fabric, with recent advancements allowing for higher operational speeds and reduced energy consumption. According to a 2022 industry report by Textile Machinery Manufacturers, state-of-the-art Chopin machines can achieve weaving speeds of up to 1,200 picks per minute, significantly improving production rates compared to older models.

When evaluating different models, consider key specifications such as shaft design, chain type, and automation features. Data from Market Research Future indicates that 68% of manufacturers prioritize machines with automated functions for reducing labor costs and minimizing human error. Additionally, the choice of materials for chain weaving—ranging from stainless steel to high-tensile synthetic fibers—affects not only the quality of the final product but also the machine's durability and maintenance requirements. By focusing on these fundamental aspects, businesses can ensure that they invest in a Chopin chain weaving machine that aligns with their production goals and operational needs.

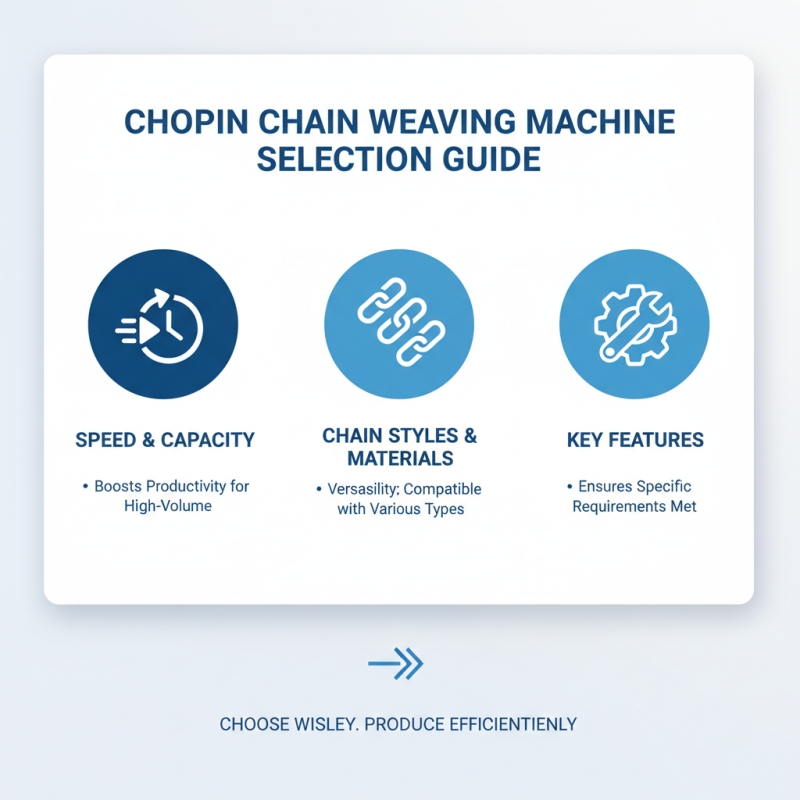

When selecting a Chopin chain weaving machine, several key features should be considered to ensure it meets your specific requirements. First, examine the machine's weaving speed and capacity. A higher speed can significantly boost productivity, making it an essential factor if you have high-volume production needs. Additionally, check the machine's compatibility with various chain styles and materials, as this flexibility can enhance your operational versatility.

Another crucial aspect is the ease of use and maintenance. Look for models that offer intuitive controls and easy setup processes, which can save time and reduce the learning curve for new operators. Regular maintenance is vital for optimal performance, so machines with accessible components for cleaning and servicing are more preferable. Finally, consider the brand’s customer support and warranty services, as reliable assistance can help address issues promptly and keep your operations running smoothly.

When selecting the best Chopin chain weaving machine, it's essential to first evaluate your production needs and requirements. Begin by assessing the scale of your operations. Are you a small artisan shop or a large industrial manufacturer? The volume of production will influence the type of machine that best fits your needs.

Smaller operations may benefit from versatile machines that allow for customization and experimentation with various patterns, while larger companies might require high-speed machines capable of handling bulk orders efficiently.

Next, consider the specific types of chains you plan to produce. Different machines are designed with varying capabilities, such as the type of materials they can handle and the complexity of the designs they can create. Understanding your target products will help narrow down your options.

Additionally, think about the required operational features, such as automation level, ease of maintenance, and the available technology for design integration. By articulating these needs clearly, you will be well-equipped to select a Chopin chain weaving machine that enhances your productivity and meets your creative aspirations.

When selecting the best Chopin chain weaving machine for your needs, it's essential to understand the differences between various brands and models available in the market. Recent industry reports indicate that advancing technology has led to significant improvements in weaving machine efficiency and functionality. For instance, machines equipped with enhanced user interfaces and automated features can reduce operation time by up to 30%, providing substantial savings for businesses that rely heavily on weaving processes.

Comparing different brands reveals that some offer specialized features tailored to specific weaving styles, such as Jacquard or tapestry weaving, while others focus on versatility across a wide range of applications. Research shows that models from top-performing brands tend to have higher customer satisfaction rates, frequently exceeding 85% due to their reliability and effectiveness. Therefore, it's crucial to evaluate your specific requirements, such as the type of fabric you intend to weave and the volume of production, to choose the machine that best aligns with your operational goals.

When selecting the best Chopin chain weaving machine, cost analysis and budgeting are crucial to ensure that the investment aligns with your business objectives. Begin by evaluating the initial setup costs associated with purchasing the machine, including delivery, installation, and any necessary training for your staff. It's essential to conduct a thorough market comparison to identify models that not only fit your weaving needs but also provide the best value for your budget. Similar to the detailed insights offered in recent reports on various manufacturing sectors, having a clear breakdown of costs can significantly aid in making an informed decision.

Furthermore, understanding long-term operational expenses such as maintenance, spare parts, and energy consumption is vital for effective budgeting. By forecasting these costs against your expected production output and potential profit margins, you can better gauge the machine’s financial viability over time. Just as businesses in other industries, like denim manufacturing and fencing production, analyze expenses meticulously, weaving operations should adopt a comprehensive approach to financial planning to maximize efficiency and cost-effectiveness.

| Machine Model | Price (USD) | Weaving Width (inches) | Production Speed (meters/min) | Maintenance Cost (annual, USD) | Comments |

|---|---|---|---|---|---|

| Model A | $12,000 | 40 | 30 | $800 | Highly recommended for small businesses. |

| Model B | $15,500 | 50 | 40 | $900 | Ideal for medium-scale production. |

| Model C | $20,000 | 60 | 50 | $1,200 | Best for large-scale weaving operations. |

| Model D | $22,000 | 72 | 60 | $1,500 | High-end model with advanced features. |