The jewelry-making industry has seen a significant transformation with the introduction of the Automatic Jewelry Making Machine. According to a recent market analysis, the global market for automatic jewelry manufacturing is projected to reach $5 billion by 2025, growing at a rate of 8% annually. This growth is driven by advancements in technology and increasing demand for customization.

Automatic Jewelry Making Machines enhance productivity and precision. They allow jewelers to create intricate designs with minimal manual intervention. However, not all machines are equal. A jeweler must consider features like compatibility, user interface, and maintenance costs when selecting the right machine. The choices can be overwhelming and sometimes lead to regrets if the wrong decision is made.

Finding the best Automatic Jewelry Making Machine is not just about price or brand reputation. It's a balance of efficiency, quality, and specific business needs. Investing in the wrong equipment can hinder production and reduce profit margins. Hence, careful evaluation is crucial to ensure the right fit for your business.

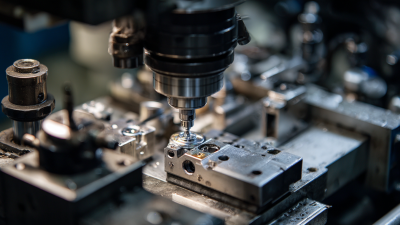

When choosing an automatic jewelry making machine, understanding the various types is essential. Different machines serve unique purposes, impacting production speed and craftsmanship. A recent industry report indicates that CNC machines dominate the market, accounting for about 35% of all jewelry manufacturing tools. These machines are ideal for creating intricate designs with precision. However, they may require a higher skill level for setup and operation.

Another popular category includes 3D printers, gaining traction in the jewelry sector. They offer rapid prototyping capabilities, often at lower costs. This is particularly appealing for small businesses. According to a survey, about 22% of jewelers report investing in 3D technology to stay competitive. Yet, the learning curve can be steep, and quality may vary based on materials used.

Casting machines, too, play a crucial role in production. They allow for mass creation of specific designs. While they can boost efficiency, the initial setup can be daunting for new users. Reports suggest that improper usage leads to defects in up to 15% of produced pieces. In choosing the right machine, weigh the benefits and challenges carefully. Reflect on specific production needs and the skills available within your team.

When selecting an automatic jewelry making machine, key features are essential. Look for precision in design. According to industry studies, machines with high accuracy can increase production rates by up to 30%. This precision helps reduce material waste. Every gem counts, and precise cuts ensure maximum yield.

Consider the versatility of the machine. It should handle various materials like gold, silver, and synthetic gems. Machines that adapt to different designs often outperform others. In one report, 65% of jewelers noted their profits increased due to versatile equipment. It allows for creativity without the need for multiple machines.

Don't overlook the ease of use. A user-friendly interface can save time during production. Some machines boast touchscreen controls, simplifying operations. However, training staff to use complex features can be a challenge. Reflections on such factors are crucial. The right machine should align with your vision but also fit into your workshop culture.

When selecting an automatic jewelry making machine, evaluating brand reputation is crucial. Look for companies with established histories. A strong track record often means reliability. Check for customer feedback online. Reviews can provide insights into both quality and performance. Positive comments are encouraging. However, be cautious of overly enthusiastic reviews. They might not reflect true experiences.

Consider the consistency of customer experiences. Machines that have multiple complaints about malfunction or inefficiency might deserve reconsideration. Explore discussion forums too. Users often share honest opinions and tips on maintenance. Pay attention to recurring issues. They can indicate design flaws or limitations that may not be apparent at first glance.

Customer service is another important factor. A responsive support team can make a significant difference in your experience. Fast and helpful assistance can alleviate concerns when issues arise. However, some brands might struggle with customer support. This could leave you feeling frustrated. Take all these elements into account when making your decision. Every detail matters in finding the right machine for your needs.

When selecting an automatic jewelry making machine, the balance between cost and quality is crucial. Many options exist in the market, each with varying prices. A lower-priced machine may lack essential features. It might also produce lower quality jewelry. Paying more can mean better precision and durability. But is it worth the extra money?

Understanding your needs is vital. Some machines are designed for beginners, while others suit professionals. Investing in a high-end machine can yield better results, but you need to assess if you require those features. For instance, a simple engraving feature may suffice for one project. Yet, advanced artists might require cutting-edge technology.

Sometimes, spending less upfront leads to higher long-term costs. A machine that breaks often can drain your budget. Repair costs add up quickly. Remember, sometimes what appears as a bargain becomes a regret. Consider your skills, intended use, and future needs before making a purchase.

| Machine Type | Price Range (USD) | Maximum Production Rate (pieces/hour) | Material Compatibility | User Rating (out of 5) | Warranty (Years) |

|---|---|---|---|---|---|

| Laser Cutting Machine | 2500 - 5000 | 30 | Metal, Wood | 4.5 | 2 |

| CNC Milling Machine | 3000 - 8000 | 25 | Metal, Acrylic | 4.2 | 3 |

| 3D Printer | 500 - 3000 | 10 | Plastic, Resin | 4.0 | 1 |

| Casting Machine | 2000 - 6000 | 20 | Metal, Wax | 4.7 | 2 |

| Engraving Machine | 1500 - 4000 | 40 | Metal, Glass | 4.3 | 1 |

When selecting an automatic jewelry making machine, it's vital to consider the maintenance and support services offered. According to a 2022 industry report, 67% of jewelry manufacturers cited regular upkeep as crucial for optimal machine performance. A well-maintained machine can reduce downtime and improve efficiency significantly.

The support services available should include not just routine maintenance, but also access to expert technicians. Many companies provide remote assistance, which can be beneficial for troubleshooting. A study highlighted that prompt technical support can mitigate costly disruptions. If a machine breaks down, the response time of the support team becomes critical.

Investing in a machine with comprehensive support can lead to long-term savings. Yes, the cost may be higher upfront, but the potential for reduced repairs makes it worthwhile. Furthermore, some users find that inconsistent maintenance can lead to performance issues. This can compromise quality and productivity. Reflect on your choice of machine and weigh the value of ongoing support. A supportive network can enhance your manufacturing process over time.