The textile industry is witnessing a significant transformation, driven by technological advancements and changing consumer demands. The demand for efficient and high-quality fabric production is pushing manufacturers to invest in advanced machinery, such as the Chopin Chain Weaving Machine. According to recent industry reports, the global weaving machine market is projected to grow at a CAGR of over 5% from 2023 to 2030, indicating a robust expansion fueled by innovation and productivity enhancements.

Selecting the right Chopin Chain Weaving Machine for your operational needs is crucial in this competitive landscape. Key factors to consider include production capacity, ease of use, and maintenance requirements. Data shows that businesses that opt for modern weaving solutions experience up to 30% increases in productivity and a 25% reduction in material waste, making the choice of machinery not only a matter of efficiency but also of economic viability. As the industry continues to evolve, understanding how to assess and choose the best equipment will position manufacturers to meet future challenges effectively and sustainably.

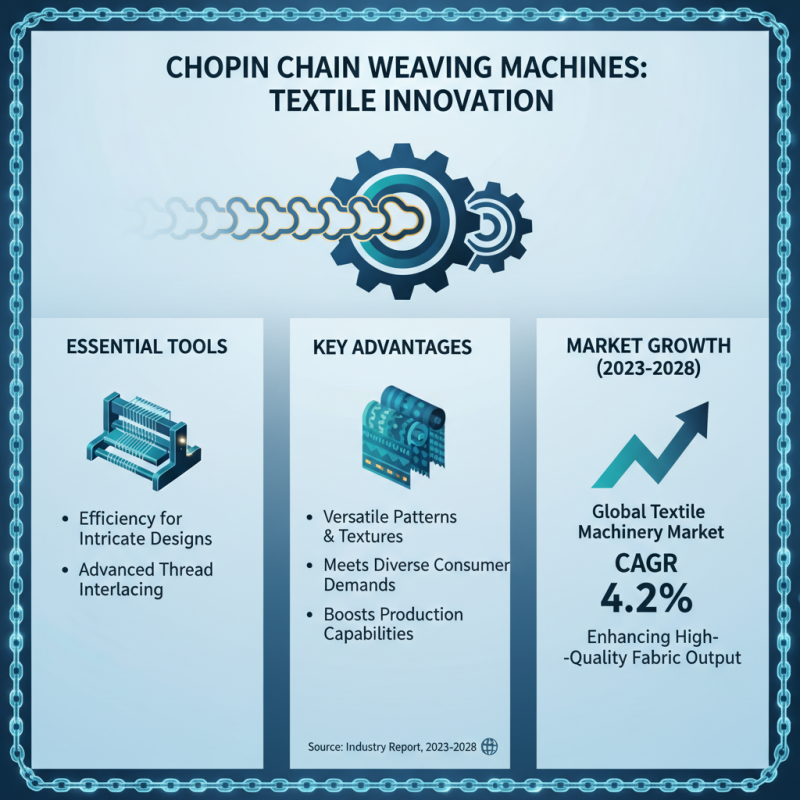

Chopin chain weaving machines are essential tools in the textile industry, known for their ability to produce intricate designs with efficiency. Understanding the basics of these machines is crucial for manufacturers looking to enhance their production capabilities. At their core, these machines leverage advanced technology to interlace threads, allowing for an array of patterns and textures that meet diverse consumer demands. According to a recent industry report, the global textile machinery market is expected to grow at a CAGR of 4.2% from 2023 to 2028, highlighting the increasing reliance on such machines for high-quality fabric production.

When evaluating a chopin chain weaving machine, it's vital to consider key factors like the machine’s specifications, production speed, and versatility. Modern machines can produce several hundred meters of woven fabric per hour, significantly reducing labor costs and time. Furthermore, advancements in automation and control technologies have led to improved precision and less material waste. Reports indicate that manufacturers who invest in high-performance weaving machines see up to a 20% increase in overall production efficiency, underscoring the importance of selecting the right equipment tailored to one's specific operational requirements.

When selecting the best Chopin chain weaving machine, it is crucial to first identify your specific weaving needs and goals. Consider the type of projects you plan to undertake—whether you're focused on creating intricate patterns, producing high volumes, or experimenting with various materials. Understanding this will help you determine the machine's capabilities, including its speed, efficiency, and versatility. For instance, if your projects involve delicate fabrics or detailed designs, you may require a machine that offers precise control and a variety of stitch options.

Additionally, assess the scale of your operations. Are you a hobbyist working on small projects or a professional looking to meet demand? This distinction can influence not only the size of the machine you need but also your budgetary considerations. A machine designed for extensive use with robust features may be a worthwhile investment if your workload is significant. On the other hand, a more compact and user-friendly model might suffice for beginners or casual users. By clarifying your requirements and objectives upfront, you can ensure that you choose a machine that aligns perfectly with your weaving ambitions.

The following chart illustrates the importance of different factors when selecting a chain weaving machine, based on a survey of potential buyers.

When selecting a high-quality weaving machine for your projects, several key features should be considered to ensure it meets your specific needs. Firstly, the machine's build quality is essential. Look for sturdy construction materials that can withstand continuous use. A robust frame reduces vibrations and enhances stability, which is crucial for producing consistent, high-quality woven products. Additionally, pay attention to the portability and size of the machine; a lightweight option may be preferable for smaller workspaces, while heavier models might provide better durability.

Another important feature is the weaving speed and efficiency. Machines that offer adjustable speeds can cater to varying project requirements, allowing you to optimize production based on fabric type and complexity. Furthermore, consider the ease of use and maintenance. User-friendly controls and straightforward setup processes can significantly reduce downtime, making your workflow more efficient. Lastly, look for machines that come with versatile attachments or optional accessories, as these can expand the capabilities of your weaving machine and allow you to experiment with different techniques and materials.

| Feature | Description | Importance |

|---|---|---|

| Weaving Speed | Higher speeds will improve productivity and efficiency in fabric production. | Critical |

| Ease of Use | User-friendly controls and interfaces enhance the operational experience. | High |

| Durability | Robust construction ensures long-term usage without frequent breakdowns. | Essential |

| Maintenance Requirements | Lower maintenance needs contribute to reduced downtime and costs. | Important |

| Flexibility | Ability to switch between various fabric types and patterns. | Moderate |

| Energy Efficiency | Machines that consume less power save on operational costs. | High |

| Technology Integration | Advanced machines with digital interfaces enable better control and monitoring. | Important |

When selecting a Chopin chain weaving machine, it is essential to compare different brands and models to find the most suitable option for your needs. According to a comprehensive industry report by Textile Machinery Review, the global demand for advanced weaving machines is expected to grow by 4.5% annually through 2025. Key factors driving this growth include increasing automation in the textile sector, enhancing production efficiency, and the demand for custom fabric designs.

When evaluating various brands, it's important to consider features such as ease of use, durability, and support services. A study conducted by the Weaving Technology Consortium highlights that machines equipped with user-friendly interfaces can reduce production errors by up to 15%, significantly impacting overall output. Additionally, examining the specifications regarding speed, loom width, and materials compatibility can also guide your decision-making process. Models that provide flexibility in handling diverse yarn types tend to score higher on customer satisfaction surveys, indicating a positive trend among users seeking adaptability in their workflows.

Furthermore, incorporating customer reviews and expert recommendations from industry publications can provide insights into the long-term reliability and performance of specific machines. Recent surveys indicate that nearly 70% of manufacturers prioritize energy efficiency and cost-saving features when selecting weaving equipment, reflecting a shift towards sustainable practices in the textile industry. Evaluating performance metrics and total cost of ownership can help ensure that your investment aligns with both current and future production needs.

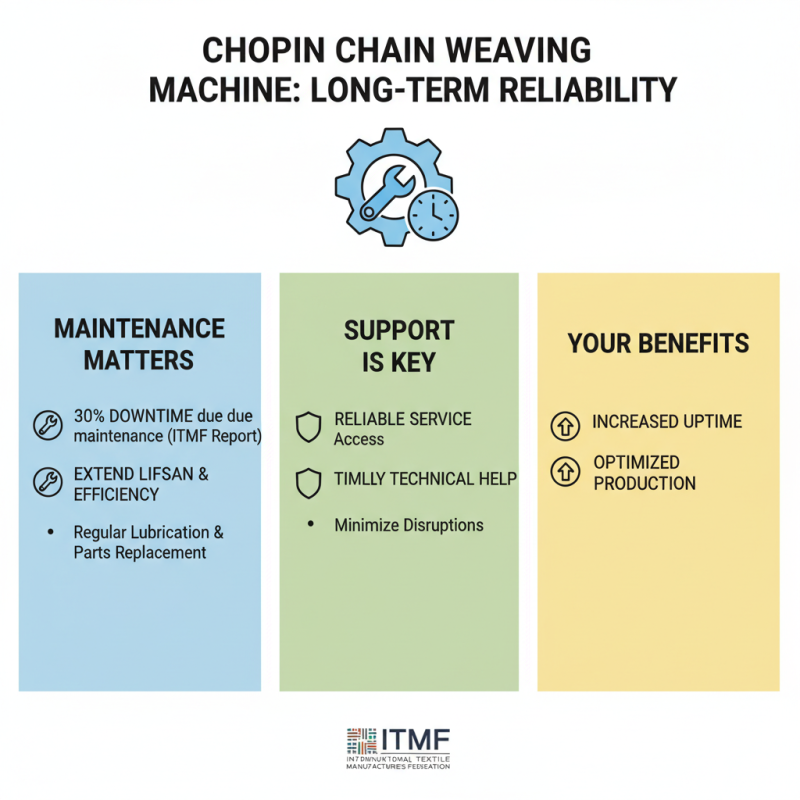

When selecting a Chopin chain weaving machine, one crucial aspect to consider is the maintenance and support required for long-term use. According to a report by the International Textile Manufacturers Federation (ITMF), approximately 30% of weaving machine downtime is attributed to maintenance issues. This highlights the necessity of not only choosing a machine that fits your production needs but also ensuring that you have access to reliable maintenance and support services. Proper maintenance routines, such as regular lubrication and timely parts replacement, can significantly extend the lifespan of your equipment and enhance operational efficiency.

Additionally, understanding the availability of spare parts and technical support is essential. Data from the Machinery Maintenance Council indicates that manufacturers with dedicated support teams can reduce operational disruptions by up to 50%. When evaluating potential machines, investigate the provider’s commitment to post-purchase support, including training, troubleshooting assistance, and access to genuine replacement parts. This focus on maintenance compatibility will play a key role in minimizing unexpected downtime and optimizing productivity in the long run.