In the realm of industrial manufacturing, selecting the right equipment is crucial for efficiency and performance. When it comes to the assembly of ball chain products, the choice of a Ball Chain Coupling Machine can significantly impact the quality of the final product. According to renowned expert in manufacturing technology, Dr. Henry Mason, "The precision and reliability of a Ball Chain Coupling Machine can make or break your production line." His insights highlight the necessity of understanding your unique production needs before making a decision.

Choosing the best Ball Chain Coupling Machine involves careful consideration of various factors, including production volume, machine specifications, and integration capabilities with existing systems. Additionally, operators must assess the long-term operational costs versus initial investment to ensure sustained productivity. With the right machine, businesses can enhance their output while maintaining the high standards expected in today's competitive market. Ultimately, the decision to invest in a Ball Chain Coupling Machine should align with both immediate operational goals and future growth strategies.

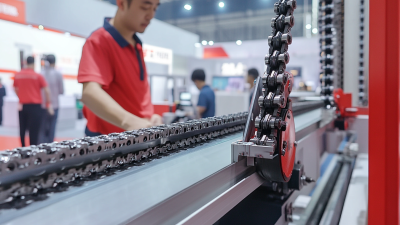

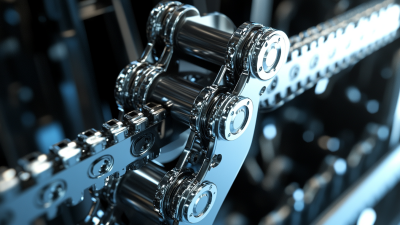

Ball chain coupling machines play a crucial role in various industries by facilitating the efficient connection of ball chains. These machines are designed to securely assemble links in a straightforward manner, ensuring that the end product meets the desired specifications. Understanding the mechanics of these machines is essential for selecting the right one for specific needs. Typically, their operation involves the precise alignment of chain links, which are then tightly connected through a series of automated processes. This not only enhances productivity but also improves the consistency of the coupling.

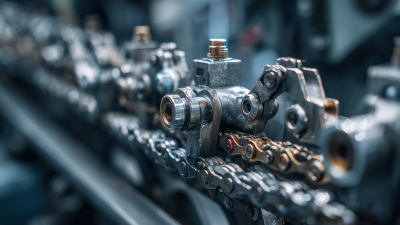

When evaluating ball chain coupling machines, it is important to consider factors such as production speed, ease of maintenance, and the range of chain sizes they can accommodate. Different models may offer varying features like adjustable settings for different chain dimensions or automated cutting functions that streamline the assembly process. Additionally, assessing the machine's build quality and design can help in ensuring longevity and reliability. By understanding these key elements, businesses can make informed decisions that align with their operational requirements and production goals.

| Feature | Description | Importance Level | Typical Range |

|---|---|---|---|

| Production Speed | Measures the output of the machine in units per hour. | High | 500 - 2000 units/hour |

| Size Compatibility | The range of ball chain sizes that the machine can accommodate. | Medium | #3 to #10 |

| Power Requirements | The voltage and phase requirements for the machine. | Medium | 220V, Single Phase |

| User Interface | The ease of use of the control panel and display. | High | Touchscreen, with manual overrides |

| Maintenance Needs | Frequency and complexity of maintenance tasks. | High | Monthly checks required |

| Price Range | The cost of the machine on the market. | High | $5,000 - $20,000 |

When selecting the best ball chain coupling machine for your needs, it’s essential to focus on several key features that can significantly impact performance and efficiency. Firstly, consider the machine's capacity and speed, as these factors determine how quickly and effectively it can meet your production demands. A machine with adjustable speed settings can provide greater flexibility for various tasks, allowing operators to optimize their workflow based on specific project requirements.

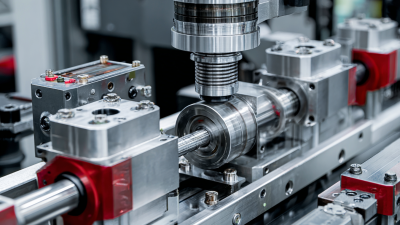

Another critical feature to pay attention to is the machine's durability and maintenance requirements. Machines built from high-quality materials tend to last longer, reducing downtime and repair costs. Additionally, seeking a machine that is easy to maintain can save time, as regular maintenance is crucial for ensuring consistent operation and longevity.

Tips: When evaluating your options, prioritize machines with user-friendly controls and interface designs. A straightforward setup can greatly enhance the overall user experience and reduce the learning curve for new operators. Furthermore, always check for warranties and support services offered by manufacturers, as this can be a key factor in ensuring a smooth operation post-purchase.

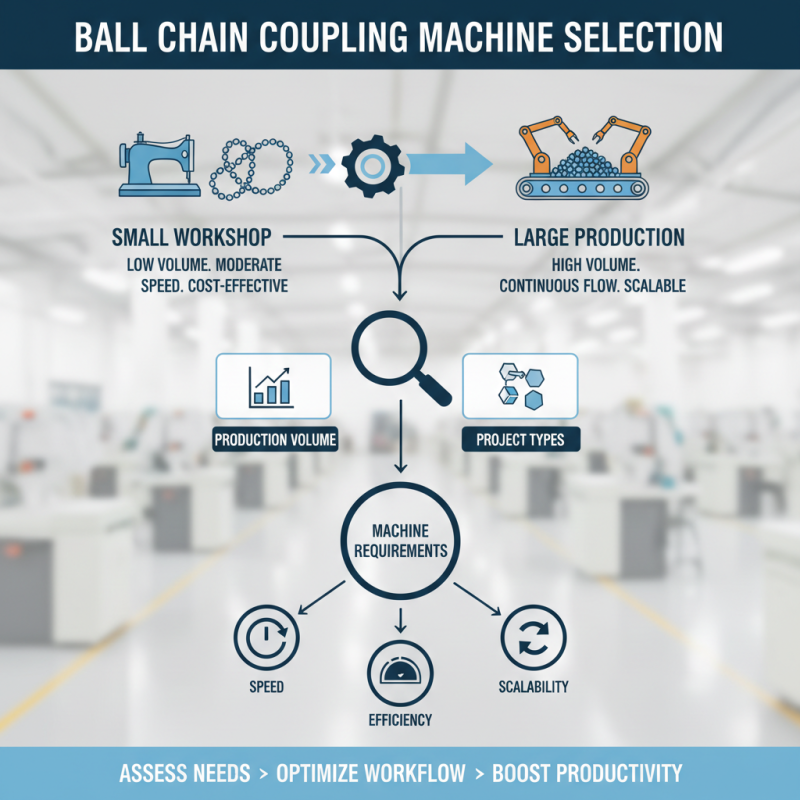

When selecting a ball chain coupling machine, the first step is to thoroughly assess your production needs. Consider the volume of production you anticipate and the types of projects you handle. These factors will help determine the machine's necessary speed, efficiency, and scalability. For instance, a small workshop with limited orders will have different requirements than a large-scale production facility that demands high throughput capabilities. Understanding your operational demands can guide you to a machine that fits your workflow and helps boost productivity without overspending on unnecessary features.

After evaluating your production needs, focus on the machine specifications to ensure they align with your requirements. Key specifications to consider include the machine's capacity, compatibility with various chain sizes, and material handling capabilities. Assess whether the machine offers automation features that can enhance efficiency, such as automatic feeding or cutting mechanisms. Additionally, consider the ease of maintenance and the availability of spare parts. By carefully aligning machine specifications with your production goals, you can select a ball chain coupling machine that not only meets your current needs but is also adaptable for future growth.

When comparing different brands and models of ball chain coupling machines, it's essential to consider several key factors that can influence your selection. First and foremost is the machine's compatibility with various chain sizes and materials. Some models are designed to handle a broader range of chains, making them more versatile for diverse projects, while others may be specialized for specific types. This flexibility can significantly affect your operational efficiency, especially if your work requires frequent changes in chain specifications.

Another critical aspect to look at is the machine's production speed and output capacity. Different models will vary in how quickly they can assemble ball chains, which is crucial for meeting production deadlines. Additionally, assessing the ease of operation and maintenance is vital. Machines that require extensive downtime for repairs or adjustments can hinder productivity. Therefore, evaluating user reviews and feedback on machine reliability and service can help you make an informed decision. By focusing on these aspects, you can better choose a ball chain coupling machine that fits your specific needs and ensures optimal performance in your operations.

When finalizing your purchase of a ball chain coupling machine, budgeting is a crucial step that can significantly influence your decision-making process. Start by assessing your specific needs and determining a realistic budget that accommodates not just the machine itself, but also ongoing costs such as maintenance, replacement parts, and operational expenses. This holistic approach ensures that you're not caught off guard by unforeseen financial commitments after your purchase.

Once your budget is established, it's essential to conduct thorough research on potential suppliers. Look for companies that have a solid reputation in the industry and are known for their quality customer service. Request quotes and compare not only the price of the machines, but also warranty terms, support services, and delivery options. Engaging with previous customers through reviews and testimonials can provide valuable insights into the reliability and performance of the suppliers under consideration. Building a good relationship with your chosen supplier can also lead to better support in future transactions, ensuring that you get the most out of your investment.

This chart compares various features of different ball chain coupling machines. The parameters include rotational speed (RPM), power (HP), material compatibility rating, maintenance frequency in hours, and price in dollars. Analyzing these features can help you make an informed decision when selecting a machine that fits your needs and budget.