As the global supply chain undergoes a transformative revolution, the demand for advanced manufacturing technologies has surged, particularly in the production of components essential to various industries.

One notable innovation is the Automatic Chain Making Machine, which has become a cornerstone in manufacturing efficiency and precision. According to a recent industry report by MarketWatch, the global market for automatic machinery is projected to grow at a compound annual growth rate (CAGR) of 7.5% from 2021 to 2025, driven largely by the increasing need for automation in supply chains.

One notable innovation is the Automatic Chain Making Machine, which has become a cornerstone in manufacturing efficiency and precision. According to a recent industry report by MarketWatch, the global market for automatic machinery is projected to grow at a compound annual growth rate (CAGR) of 7.5% from 2021 to 2025, driven largely by the increasing need for automation in supply chains.

China, as the leading player in this sector, has been at the forefront of innovation, producing the most advanced Automatic Chain Making Machines that not only enhance productivity but also ensure quality standards. This blog will delve into the 2025 industry dynamics, comparing different technologies and their impact on the global supply chain landscape, highlighting how China’s advancements are setting new benchmarks in the realm of automatic machinery.

In recent years, China has emerged as a powerhouse in the manufacturing of automatic chain making machines, significantly influencing global markets. The rise of these advanced machines has revolutionized the production processes for many industries, including automotive, construction, and marine applications. China's investment in automation technology has enabled manufacturers to produce high-quality, efficient, and cost-effective chain solutions, catering to a diverse range of customers worldwide.

The adoption of automatic chain making machines offers manufacturers several advantages, including increased production speed and reduced labor costs. With China leading the charge, companies are now able to achieve greater precision in chain manufacturing, leading to enhanced product reliability and performance. As Chinese manufacturers continue to innovate and improve their machinery, they are not only setting new standards in the industry but also making significant strides in exporting these technologies to countries around the globe, further solidifying China's role as a leader in the global supply chain landscape.

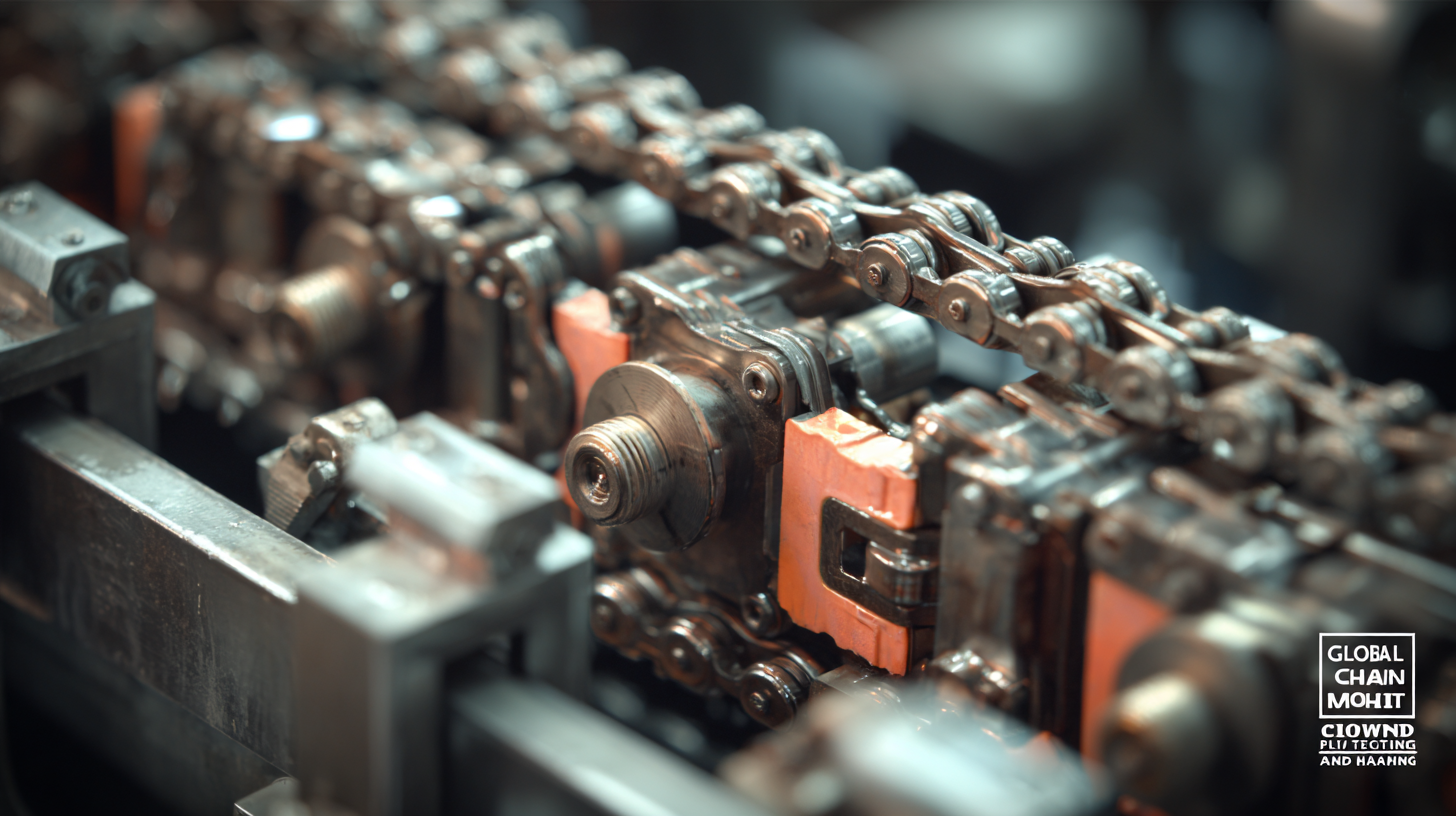

China is transforming its supply chain operations through innovative technologies, particularly in the manufacturing of automatic chain making machines. These advanced machines not only enhance productivity but also ensure high precision, significantly reducing waste and costs. The incorporation of AI and IoT in chain manufacturing allows for real-time monitoring and adjustments, fostering a more agile response to market demands.

Tips for leveraging these technologies include investing in training staff on the latest machinery to ensure maximum efficiency. Additionally, companies should embrace data analytics to track production processes and identify areas for improvement. By prioritizing technology integration, businesses can enhance their competitiveness in the global market.

Another crucial aspect is collaboration across supply chains. Open communication between suppliers and manufacturers can lead to better forecasting and inventory management. Companies should consider regular partnerships with tech firms to stay updated on emerging trends, which can further strengthen their supply chain resilience and innovation.

China has emerged as a global leader in manufacturing automation, particularly in the realm of chain production. With advancements in technology and a workforce that adapts quickly to automation, the country has successfully positioned itself at the forefront of the industry. According to a report by the International Federation of Robotics, China accounted for approximately 36% of all industrial robot installations worldwide in 2021, highlighting the nation's commitment to enhancing its manufacturing capabilities through automation.

The advantages that China holds in this sector stem from several factors. Firstly, the scale of production in Chinese factories allows for substantial economies of scale, driving down costs and increasing efficiency. The National Bureau of Statistics of China reported that the country’s manufacturing output reached over $4 trillion in 2020, which provides manufacturers with the resources to invest in cutting-edge machinery. Furthermore, the Chinese government's support for automation initiatives—through subsidies and infrastructure development—has also played a crucial role in accelerating the technological advancements in chain manufacturing processes.

Additionally, Chinese companies have been at the forefront of innovative technologies, such as smart manufacturing and the Internet of Things (IoT), which enhance operational workflows. Reports suggest that companies integrating these technologies see efficiency improvements of about 30% and cost reductions of 20% on average. This competitive edge in automation not only boosts productivity but also positions China as a vital hub in the global supply chain, particularly for high-quality chain-making machines that meet international standards.

China's pivotal role in global supply chains is underscored by recent developments in various sectors, particularly as it continues to export quality products. In the pharmaceuticals industry, China's dominance in active pharmaceutical ingredient (API) production is reshaping global dynamics. The World Trade Organization reports that over 40% of the world's APIs are produced in China, highlighting its crucial position in ensuring a reliable supply for markets worldwide. This dominance has profound implications as countries seek to secure their pharmaceutical supplies amid ongoing trade tensions and disruptions.

Moreover, China's strategic decision to remove the export tax rebate for aluminum and copper, effective December 1, 2024, signals a significant shift in global trade dynamics. As noted in recent industry analyses, this change may reset pricing strategies and supply chain dependencies across continents, impacting both emerging markets and developed economies heavily reliant on these raw materials. Furthermore, the recent tariff surges implemented by the United States are reshaping trade flows, compelling nations to navigate a complex landscape of tariffs and value chains. Such shifts challenge countries to adapt their export strategies while reinforcing China's central role in the global supply chain framework, particularly in manufacturing and resource sectors.

| Product Type | Export Volume (Units) | Destination Region | Market Demand (Growth %) | Technology Level |

|---|---|---|---|---|

| Automatic Chain Making Machine | 50,000 | North America | 15% | Advanced |

| Manual Chain Making Machine | 30,000 | Europe | 10% | Intermediate |

| Heavy Duty Chain Making Machine | 20,000 | Asia-Pacific | 8% | High |

| Mini Chain Making Machine | 25,000 | Latin America | 12% | Basic |

In recent years, China has emerged as a leader in the automatic chain production sector, largely due to the integration of cutting-edge technology and innovative manufacturing processes. As industries worldwide demand higher efficiency and precision, Chinese manufacturers have responded by adopting advanced automation solutions. This revolution in chain-making technology not only enhances productivity but also improves the quality of the final products, allowing for quicker turnarounds and reduced operational costs.

Looking ahead, the future of automatic chain production in China holds exciting possibilities. With the continuous development of artificial intelligence and machine learning, we can expect even more sophisticated machinery that adapts to real-time manufacturing needs. Moreover, the emphasis on sustainable practices is driving companies to develop eco-friendly production methods, minimizing waste and energy consumption. As these trends take shape, China is poised to remain at the forefront of the global supply chain revolution, setting benchmarks for efficiency, sustainability, and innovation in the automatic chain industry.