Centrifuge Jewelry has emerged as a captivating trend in the modern jewelry design landscape, combining artistry with innovative technology. This technique utilizes a centrifuge to create unique designs that often feature dynamic patterns and textures. The growth of interest in Centrifuge Jewelry can be seen in market reports, which indicate that the global jewelry market size is projected to reach USD 480 billion by 2025, with segments like custom and artisan jewelry gaining immense popularity among consumers.

As sustainable practices become increasingly important, Centrifuge Jewelry offers an avenue for eco-conscious designs, utilizing materials in a more resource-efficient manner. According to a report by the Jewelers of America, 61% of millennials prefer brands that focus on sustainability, highlighting a significant shift in consumer preferences. The meticulous crafting process behind Centrifuge Jewelry not only allows for intricate designs but also meets the demand for personalization and uniqueness that today’s consumers seek. This innovation in jewelry making presents opportunities for both artisans and customers to engage in a more dynamic and meaningful relationship with their adornments.

Centrifuge jewelry is an innovative and artistic form of adornment that utilizes the principles of centrifugal force to shape and create unique pieces. Unlike traditional jewelry-making methods, which often rely on handcrafting or casting, centrifuge jewelry leverages technology to produce intricate designs that showcase a blend of art and science. This technique allows for the manipulation of materials, such as resin and metals, in a way that can yield stunning patterns and textures.

The process begins with the selection of raw materials that can withstand the spinning process. Once the materials are prepared, they are placed in a centrifuge, which spins at high speeds. This rapid rotation causes the materials to move outward, allowing them to blend and flow into specific molds. As the materials settle and harden, the results are often mesmerizing, leading to the creation of one-of-a-kind pieces that reflect the dynamic nature of the crafting process. Each item radiates a sense of individuality and spontaneity, making centrifuge jewelry a captivating choice for those seeking distinctive accessories.

This chart illustrates the average time taken in hours for each stage of the Centrifuge Jewelry production process, highlighting the efficiency of different phases from design to quality control.

Centrifuge jewelry is a unique fusion of art and science, employing principles of centrifugal force to create distinctive pieces. The process revolves around the use of a centrifuge, which spins materials at high speeds, allowing for the manipulation of elements such as resin, pigments, and natural specimens. As the centrifuge operates, it generates a force that effectively distributes these materials throughout the mold, resulting in a harmonious blend of colors and textures. This mechanism also allows for the encapsulation of organic items, such as flowers and leaves, creating a striking visual effect.

The scientific principles behind centrifuge jewelry creation hinge on several key concepts. Centrifugal force, generated by the spinning motion, causes denser materials to move outward while lighter components remain closer to the center. This phenomenon can be harnessed to control the layering and integration of various materials, leading to a multi-dimensional appearance in the final product. Additionally, the rapid spinning aids in the curing process of resins, promoting quicker and even solidification. By understanding and manipulating these scientific factors, artisans can craft jewelry pieces that are not only aesthetically pleasing but also structurally sound, showcasing the beauty of both nature and technology.

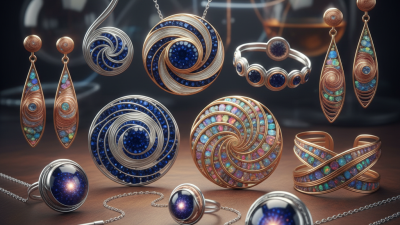

Centrifuge jewelry is a unique and innovative form of adornment that utilizes a specific production technique to enhance its aesthetic appeal. The materials chosen for the creation of centrifuge jewelry play a crucial role in determining not only the visual impact but also the durability and overall quality of the pieces. Commonly used materials include various metals, such as sterling silver and gold, which provide a solid foundation for intricate designs. These metals are often selected for their malleability and ability to withstand the centrifugal forces encountered during production.

In addition to metals, centrifuge jewelry often incorporates a variety of non-metal materials, such as resins, gemstones, and organic elements. The inclusion of resins allows for vibrant colors and patterns, which can be accentuated by the spinning action of the centrifuge, creating dynamic visual effects. Gemstones, whether natural or synthetic, can add a touch of elegance and uniqueness to each piece, appealing to different tastes and styles. Organic materials like wood or dried flowers can also be incorporated, providing a connection to nature while adding distinct character to the jewelry. The careful selection and combination of these materials contribute significantly to the final product, making each item a one-of-a-kind piece of art.

Centrifuge jewelry is a unique form of adornment that incorporates resin and various materials into stunning pieces. The process of making this jewelry involves several meticulous steps. First, artisans select the materials they wish to showcase. These can range from dried flowers and leaves to captivating stones or even small objects, all chosen for their aesthetic appeal and personal significance.

Once the materials are selected, the next step involves preparing the resin mixture. Artisans carefully measure and mix a two-part epoxy resin, ensuring proper proportions to guarantee a durable final product. After the resin is prepared, the selected materials are arranged within a mold. The mixed resin is then poured over these materials, completely encasing them. This step is crucial, as it determines the final look of the piece. After pouring, the molds are placed in a centrifuge, which spins them to eliminate air bubbles and evenly distribute the resin. Once the resin has cured, the jewelry is carefully removed from the mold, sanded, and polished, highlighting the unique elements trapped within the resin, resulting in a one-of-a-kind piece of jewelry.

| Step | Description | Materials Used |

|---|---|---|

| 1 | Gather design ideas and create sketches. | Paper, Pencil |

| 2 | Select appropriate materials for the jewelry. | Resin, Gemstones, Metals |

| 3 | Prepare the mold and mix the resin. | Silicone Mold, Resin Kit |

| 4 | Pour the mixed resin into the mold. | Prepared Mold, Mixed Resin |

| 5 | Use a centrifuge to spin the jewelry to remove bubbles. | Centrifuge Machine |

| 6 | Cure the resin as per specifications. | UV Light or Heat Source |

| 7 | Remove the cured jewelry from the mold. | Cured Jewelry |

| 8 | Finish the jewelry with polishing and adding findings. | Polishing Tools, Jewelry Findings |

Centrifuge jewelry design is gaining traction as a unique and innovative approach to modern accessories. This technique utilizes the principles of centrifugal force to create intricate patterns and textures that are impossible to achieve through traditional methods. By spinning materials at high speeds, designers can manipulate various elements like resin, metals, or natural materials to form stunning visual effects. The versatility of this method allows for a wide array of applications, catering to diverse tastes and styles, from avant-garde statement pieces to subtle, elegant designs.

Current trends in centrifuge jewelry often emphasize sustainability and customization. Many artisans are integrating eco-friendly materials and practices into their creations, appealing to environmentally conscious consumers. Moreover, the ability to personalize pieces through color choices and embedded elements is becoming increasingly popular. This trend not only reflects individual style but also the emotional connections that wearers develop with their jewelry.

As interest in centrifuge jewelry continues to grow, it is likely that we will see even more creative innovations and applications that push the boundaries of traditional jewelry design.