The "Box Chain Making Machine" is an essential tool in modern manufacturing. It efficiently produces strong, durable chains used in various industries. John Smith, a leading expert in machinery design, once stated, "Understanding the capabilities of a Box Chain Making Machine can revolutionize production lines."

These machines operate on precise mechanics, making them a vital asset. The process begins with raw materials fed into the machine, where they are formed into specific shapes. Each link of the chain is meticulously crafted, ensuring quality and consistency. However, fine-tuning settings can be challenging. Small adjustments can significantly affect the output.

Despite their efficiency, operators must remain vigilant. Minor errors can lead to production delays or defects. The Box Chain Making Machine requires regular maintenance to ensure optimal performance. Understanding its complexities is crucial for maximizing its potential. Only then can manufacturers truly harness its benefits. This intricate balance of precision, skill, and awareness defines the industry's landscape.

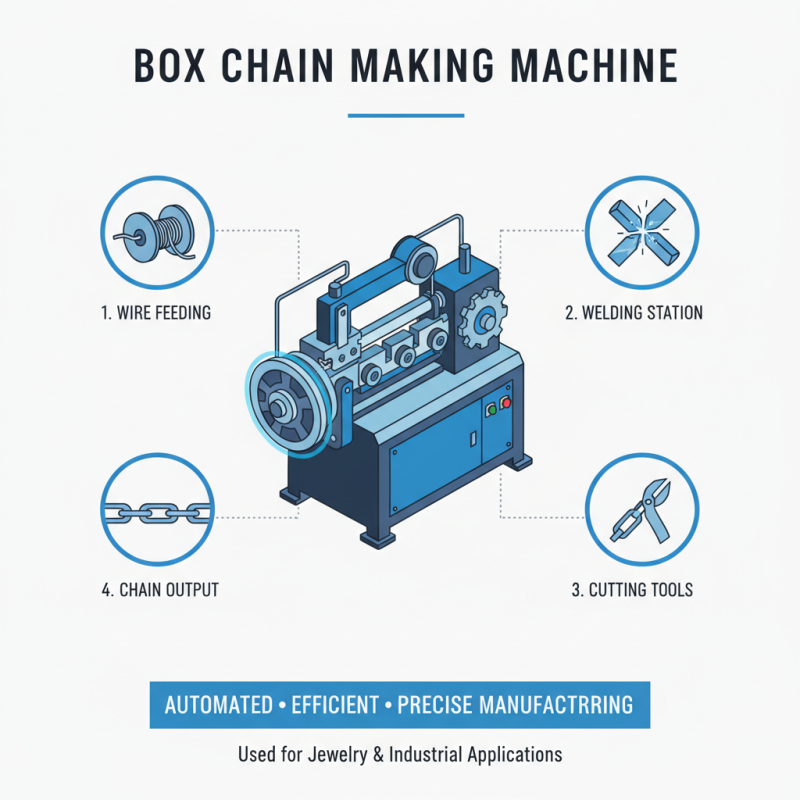

A box chain making machine is a specialized device used to produce metal box chains. These chains are commonly used in jewelry and various industrial applications. The machine automates the process, allowing for efficient and precise manufacturing. It consists of several parts, including wire feeding mechanisms, welding stations, and cutting tools.

One key aspect of a box chain making machine is its ability to create uniform links. Each link is shaped into a box form, enhancing durability. The entire process begins with raw wire, which is bent into shapes and linked together through welding. The machine operates at high speeds, reducing production time significantly.

Tip: Regular maintenance is crucial for optimal performance. Check the settings and components frequently to avoid malfunctions.

Despite the machine’s efficiency, it requires skilled operators. Understanding the nuances of the equipment is essential. An inexperienced hand might miss crucial adjustments.

Tip: Always keep a manual nearby for troubleshooting. This can save you time and frustration during production.

In conclusion, although the box chain making machine simplifies the process, complexity still exists. Proper training and constant vigilance can enhance the output quality.

A box chain making machine is designed for producing box chains used in various applications. These machines consist of several key components. The main part is the chain-making mechanism, which drives the entire process. It uses a series of rollers to shape and loop the metal into distinct box-style links.

Another essential component is the feeding system. This system ensures a continuous supply of raw material. Accurate measurement is crucial here. Any error can lead to inconsistencies in chain quality. Additionally, the welding unit binds the links together. It often employs advanced techniques for high durability.

The control panel allows operators to adjust settings easily. This feature can be both a blessing and a curse. While it offers precision, operating it requires training. Misunderstandings can lead to production issues. Regular maintenance is vital as well, yet it often gets overlooked. A simple oversight could result in costly downtime.

A box chain making machine is a specialized tool used in jewelry and industrial applications. Its purpose is to create strong, interlinked chains with uniform links. The machine operates through a series of steps that transform raw materials into finished chains.

Initially, the wire is fed into the machine, which cuts it into specific lengths. This length is crucial. If it’s too short, the links won't connect properly; if too long, the chain may be bulky. After cutting, the machine bends the wire into a loop. This loop will form the foundation for the chain link. Precision is key here. Each loop must be consistent in size to ensure the final product is uniform.

Next, the machine twists the loops into interconnected links. This step requires careful calibration. If the tension is too tight, the links can break; if it's too loose, they may not bind securely. Finally, the links are polished for smoothness and shine. Throughout this process, adjustments may be needed to maintain quality. Embracing imperfections can lead to improvements in design and functionality. Each box chain tells a story of precision and creativity, bringing together both art and machinery.

Box chain making machines are critical in various industries. These machines serve multiple applications, especially in manufacturing chains used for securing and lifting loads. In fact, the global market for industrial chains is projected to reach $6 billion by 2025, highlighting the importance of efficient machinery.

In the automotive sector, for instance, chains made by these machines are vital for power transmission. They enhance performance and reliability. Similar applications exist in the agricultural field, where box chains are used in conveyor systems for moving goods. Additionally, the packaging industry heavily relies on box chains for assembling and transporting products. Notably, reports show a demand surge in these sectors, emphasizing the machine's pivotal role.

Despite their efficiency, there are challenges. Machine maintenance can be complex and costly. Operators sometimes overlook this, leading to breakdowns. Moreover, the precision required in manufacturing box chains can vary, prompting manufacturers to reassess quality control measures regularly. Balancing cost and quality remains a persistent concern across industries.

A box chain making machine is an important tool in various industries. It produces chains used in many applications, including transport and manufacturing. One major benefit of using this machine is its efficiency. These machines can create large quantities of chains quickly, saving valuable time in production processes.

Another advantage is the precision they offer. The machine operates with high accuracy, ensuring uniformity in chain links. This consistency is crucial for quality control. However, achieving this requires proper maintenance and calibration. Neglecting these aspects can lead to defects, an area where operators must remain vigilant.

Moreover, investing in a box chain making machine can lead to cost savings. Producing in-house reduces dependence on external suppliers. Yet, businesses should consider the initial costs and training needed. Choosing the right machine can be challenging. Companies must evaluate their specific needs carefully.