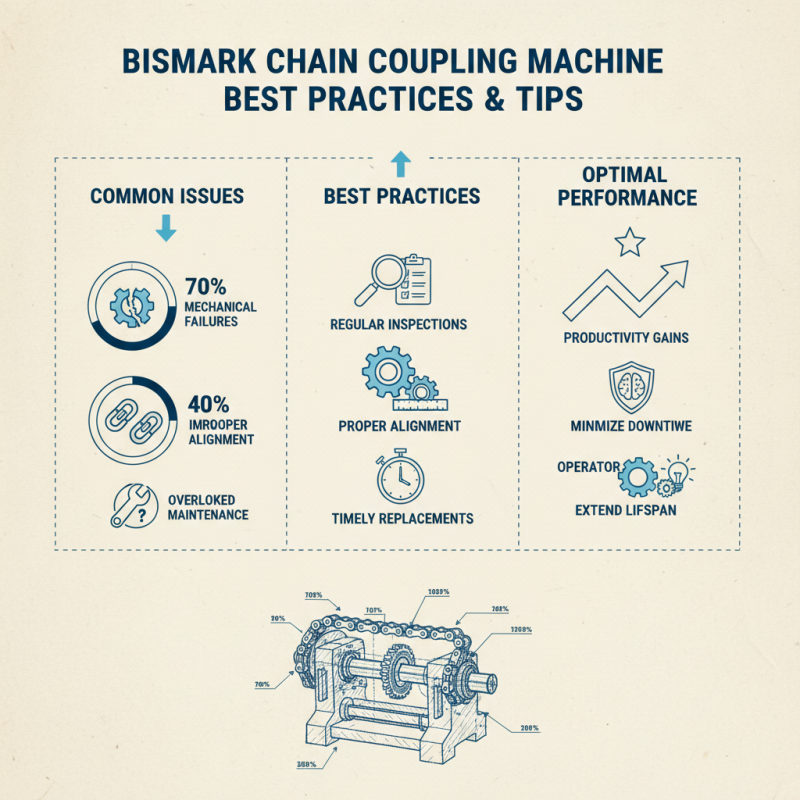

The Bismark Chain Coupling Machine is essential in various industrial applications. According to industry reports, over 70% of mechanical failures are due to improper coupling. Effective practices can minimize downtime and enhance performance. Optimal use of the Bismark Chain Coupling Machine can lead to significant productivity gains.

Understanding the best practices is crucial. Engineers often overlook basic maintenance, which leads to unexpected issues. Regular inspections and timely replacements can prevent these setbacks. Surprisingly, 40% of users are unaware of the proper alignment techniques essential for efficient operation.

Learning and adapting to these practices is vital. Each machine has unique quirks that need attention. Recognizing the signs of wear and tear can extend its lifespan. Implementing regular training sessions for operators could address knowledge gaps. Many companies still struggle with these challenges. A proactive approach is key to harnessing the full potential of the Bismark Chain Coupling Machine.

Bismark Chain Coupling Machines are essential tools in various industries, primarily for connecting and transmitting motion between components. These machines facilitate smooth operation and can significantly enhance efficiency in machinery performance. According to a recent industry report, about 70% of mechanical failures stem from coupling issues. This highlights the need for proper maintenance and understanding of these components.

Regularly inspecting and maintaining Bismark Chain Coupling Machines can prevent costly downtime. It's crucial to check for wear and tear, as even minor distortions can lead to significant operational problems. Ensure that the chains are lubricated adequately. Insufficient lubrication can increase friction, leading to premature equipment failure.

Tip: Always keep a maintenance log. Documenting service dates and issues will help identify recurring problems.

Training operators on best practices is vital. They must understand the operational limits of the coupling machines to avoid overloads. Overuse can lead to catastrophic failures. Regular training sessions can empower teams to recognize the signs of wear early and take prompt action.

Tip: Conduct periodic workshops on coupling machine operation. Knowledge is power in maintaining equipment longevity.

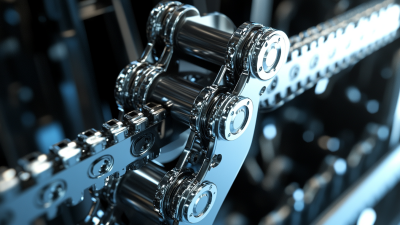

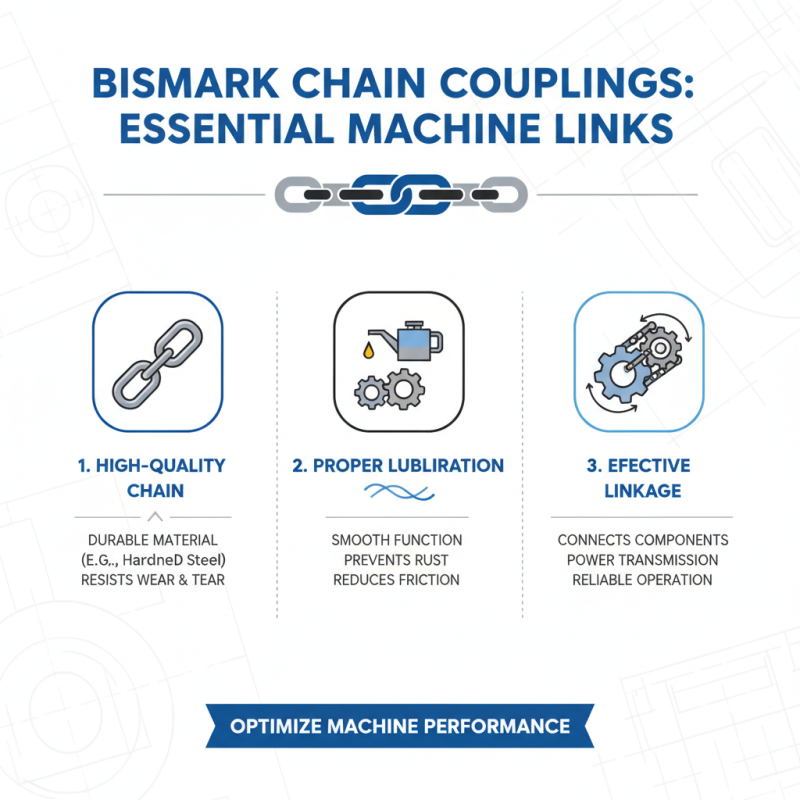

Bismark chain couplings are essential in various machines, linking components effectively. Several key components ensure their performance and durability. The chain itself is a critical part. It should be made of high-quality material to withstand wear and tear. Proper lubrication is vital to keep the chain functioning smoothly and to prevent rust.

Another important component is the sprocket. Sprockets need to be precisely aligned with the chain. Misalignment can lead to premature wear. Regular inspections can help identify any alignment issues early. Additionally, the tensioning mechanism is crucial for maintaining the right stress on the chain. Too much tension can cause damage, while too little can result in slippage.

While understanding these components, it's important to reflect on maintenance practices. Some users overlook regular checks, which can lead to serious problems. Keeping a maintenance log can aid in tracking performance and issues. Being proactive is better than reactive when dealing with machinery. Regular assessment of all components allows for smoother operation and longer equipment life.

When setting up a Bismark chain coupling machine, precision is key. According to a recent industry report, improper installation can lead to efficiency losses of up to 20%. Ensure that all components are aligned correctly to prevent unnecessary wear. Using a laser alignment tool can significantly enhance accuracy during installation. Measurements should be taken multiple times to avoid any discrepancies.

During the setup, it's essential to pay attention to torque specifications. An under-torqued connection can result in slippage, whereas over-torquing may damage the components. Industry data indicates that over-tightening can reduce the lifespan of the coupling by up to 30%. Regularly check the coupling's tension after the first few hours of operation. If you notice any unusual vibrations, reevaluate your setup.

Additionally, environmental factors should not be overlooked. Dust, moisture, and temperature fluctuations can all affect performance. Regular maintenance schedules are crucial. Ignoring small issues can lead to larger failures down the line. Take the time to train your team on best practices. Mistakes may happen, but acknowledging them can lead to improved setups in the future.

Maintaining a Bismark chain coupling machine requires diligence and knowledge. Proper care increases its lifespan and efficiency. According to industry research, regular maintenance can improve performance by up to 30%. To achieve this, adhere to essential maintenance practices.

One vital tip is to inspect the chain regularly. Look for signs of wear or damage frequently. A worn chain can lead to increased friction and energy loss. Use a lubricating oil specifically designed for high-load applications. This minimizes wear on the coupling and can extend the life of the chain significantly.

Another best practice involves monitoring operating conditions. Excessive vibrations or heat can indicate underlying issues. If temperatures exceed recommended levels, this can deteriorate performance over time. Addressing these issues quickly can prevent costly repairs down the line.

Lastly, keep the surrounding area clean. Dirt and debris can interfere with the chain's movement. A clean environment enhances operational efficiency. Tracking these details ensures you maximize your machine’s potential. Regular maintenance and care can make a notable difference in performance.

When working with Bismark chain couplings, some common issues may arise, impacting performance and efficiency. One frequent problem is misalignment. Misalignment can lead to increased wear and noise. Regularly check the alignment during maintenance to prevent this issue.

Another common challenge is chain slack. Over time, chains may loosen, leading to inadequate performance. Regular inspections can help identify slack. Adjust the tension as needed to maintain optimal functionality.

Tips: