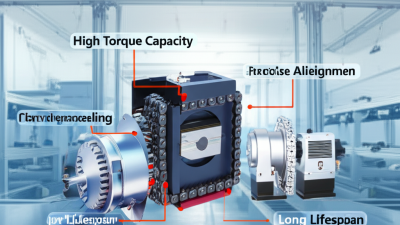

The Bismark Chain Coupling Machine is an innovative solution in mechanical engineering. This machine plays a crucial role in enhancing operational efficiency. It connects two rotating shafts securely, allowing for reliable power transmission.

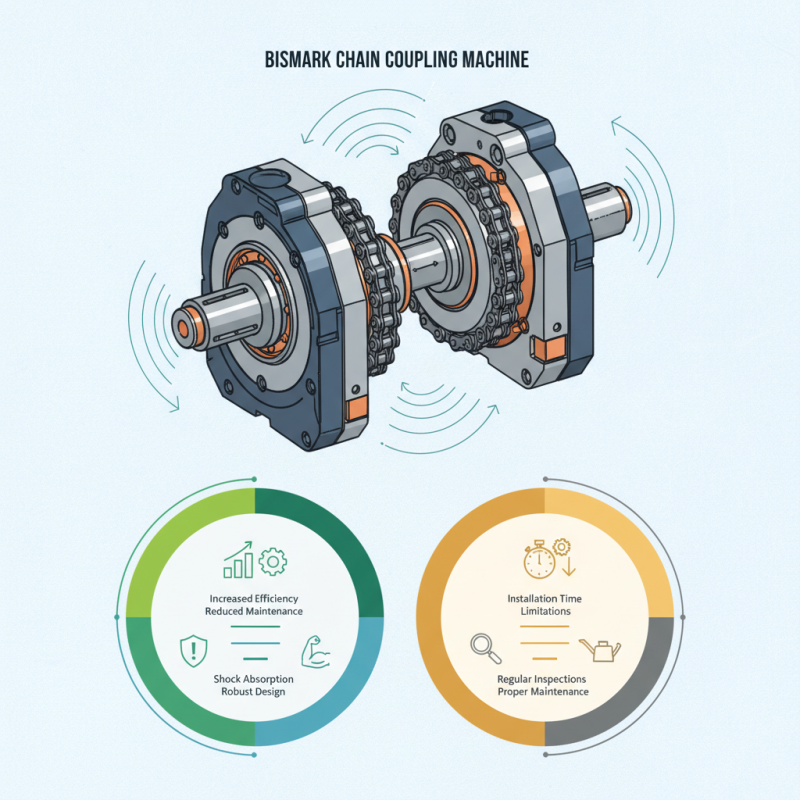

One notable advantage is its ability to absorb shock loads. This feature reduces wear and tear on machinery. Users often report a significant decrease in maintenance costs due to the Bismark Chain Coupling Machine. Its robust design ensures long-lasting performance even in challenging conditions. However, some might find its installation process a bit time-consuming.

The Bismark Chain Coupling Machine is becoming increasingly popular. Many industries are adopting it for its reliability and effectiveness. Yet, it is essential to remember that, like any technology, it has limitations. Regular inspections and proper maintenance are necessary to maximize its potential.

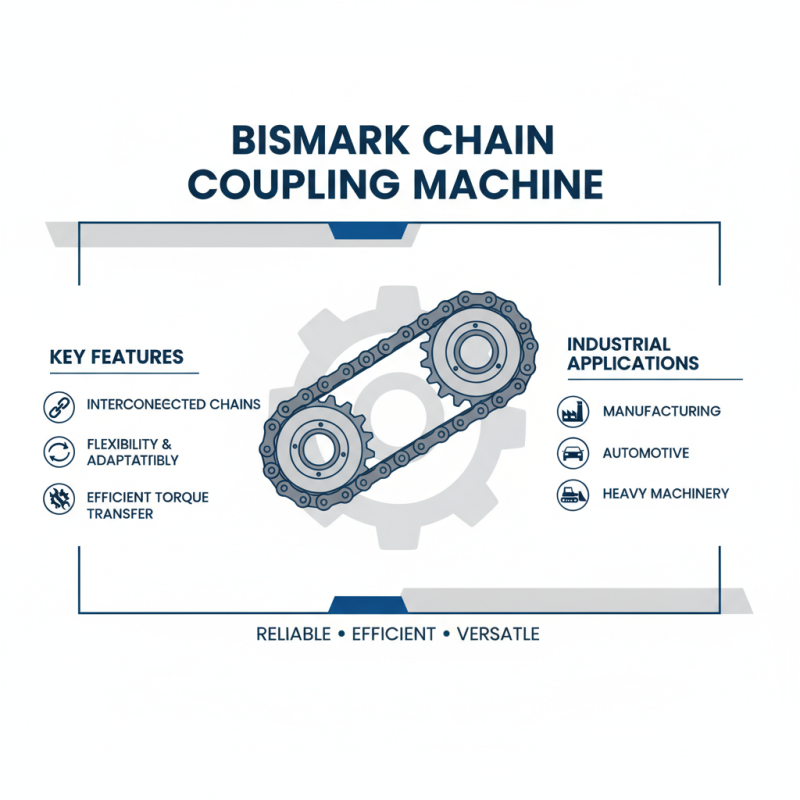

The Bismark Chain Coupling Machine is an essential tool in various industrial applications. It combines multiple components through a series of interconnected chains. This design enables significant flexibility and adaptability. Its structure allows for effective torque transfer during operation. Many industries utilize these machines for their efficiency and reliability.

Recent reports indicate that chain coupling machines can reduce operational downtime by up to 30%. This is impressive, especially in manufacturing environments where continuous production is crucial. The ability to handle high loads and harsh conditions makes the Bismark Chain Coupling popular among engineers. However, it is essential to acknowledge potential weaknesses. Regular maintenance is essential to avoid unexpected failures. Neglecting this aspect may lead to costly repairs.

In addition, some users have reported challenges with initial setup. Complex installation procedures can deter quick implementation. Training staff to use this machine efficiently is also necessary. The benefits of using the Bismark Chain Coupling Machine become evident when these factors are addressed properly. Performance improves dramatically when teams understand its capabilities and limitations.

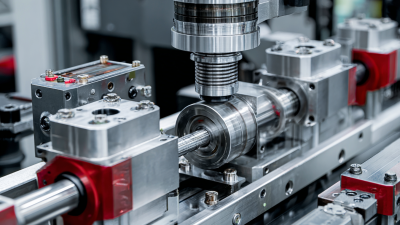

The Bismark Chain Coupling Machine is an innovative piece of equipment. Its key components include high-quality chains, durable sprockets, and efficient drive systems. Each part contributes to the machine's performance and longevity.

Chains in the Bismark machine are designed for strength. They withstand heavy loads and resist wear. Durable sprockets ensure smooth operation. They maintain alignment and reduce friction, which enhances efficiency. Drive systems power the machine and ensure consistent speed.

Tip: Regular maintenance of these components can extend their lifespan. Check for wear and tear frequently. This simple act can prevent costly breakdowns.

Another important aspect is the assembly process. It requires precision to ensure all parts fit perfectly. Even a slight misalignment can cause problems. The machine may not function optimally, leading to reduced performance.

Tip: Follow the manufacturer's guidelines closely. This helps avoid mistakes during setup. Proper assembly is crucial for long-term success.

| Component | Description | Benefits |

|---|---|---|

| Chain Assembly | Durable chain links designed to transmit power efficiently. | Provides high torque transmission and longevity in harsh conditions. |

| Coupling Hubs | Connects the chain to the machine's drive shaft. | Ensures secure coupling and minimal power loss during operation. |

| Tension Adjusters | Mechanisms to maintain optimal chain tension. | Prevents slippage and extends the lifespan of the chain. |

| Guide Rails | Structures that keep the chain aligned during operation. | Increases efficiency by reducing wear and tear on components. |

| Lubrication System | System for applying grease or oil to reduce friction. | Enhances performance and reduces maintenance needs. |

The Bismark Chain Coupling Machine operates on a simple yet effective principle. It uses a series of interlocking chains to transfer power between components. This mechanism allows for greater flexibility in movement. Its design minimizes wear and tear on gears and other parts. This reduces maintenance needs and extends equipment lifespan.

Performance data indicates that machines using chain couplings can reduce energy loss by up to 15%. This is vital in industries striving for efficiency. In environments with high loads, these couplings maintain stability under pressure. However, there is room for improvement. While they are robust, they can be susceptible to stretching over time. Regular inspections are crucial to ensure optimal function.

Another interesting aspect is adaptability. The design allows for customization based on specific needs. This adaptability can lead to challenges in standardization. When different industries require unique configurations, it complicates production and training. Engineers must balance customization with efficiency. The focus on versatility can introduce unforeseen complexities in the overall process.

The Bismark Chain Coupling Machine has gained traction in various industries due to its unique benefits. One key advantage lies in its ability to reduce vibration and misalignment in machinery. A recent industry report highlighted that misalignment can cause up to 30% of machinery failures, leading to costly downtime. Using a Bismark Chain Coupling can minimize this risk, enhancing operational efficiency.

Another notable benefit is durability. These machines often feature high-strength materials that withstand heavy loads and harsh environments. According to data from machinery maintenance studies, reliable coupling systems can improve machine lifespan by as much as 25%. Regular maintenance of couplings can further extend their life, which is crucial for reducing operational costs.

**Tips:** Regularly inspect your coupling machines for wear and tear. Early detection can save significant repair costs. Additionally, consider the installation environment. Proper alignment and operating conditions can influence overall performance. Always follow manufacturer guidelines for best results.

The Bismark Chain Coupling Machine offers numerous advantages in various industrial applications, including increased efficiency, reduced maintenance needs, cost savings, enhanced durability, and improved overall performance. The chart above illustrates the percentage benefits realized by organizations that implement these machines.

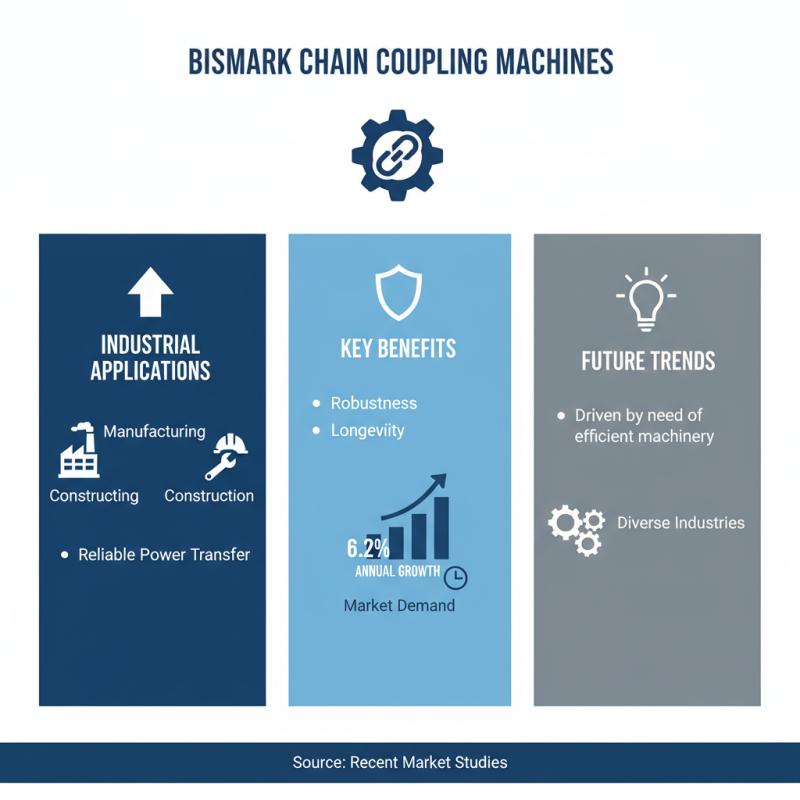

Bismark Chain Coupling Machines are remarkable in various industrial applications. They provide reliable power transfer solutions in sectors like manufacturing and construction. Industries often leverage these machines for their robustness and longevity. According to recent market studies, the demand for chain coupling solutions is projected to grow by 6.2% annually. This rise is fueled by the increasing need for efficient machinery in diverse industries.

Manufacturers utilize Bismark Chain Coupling Machines in assembly lines, conveyor systems, and even mining equipment. These machines withstand high loads, ensuring minimal downtime. Reports suggest that businesses using such systems can improve operational efficiency by up to 15%. However, users should consider that maintenance is key. Neglecting regular checks can lead to failures, impacting productivity.

Tips: Always inspect chain coupling regularly. Look for signs of wear and tear. This proactive approach can save time and resources down the line. Remember, not every solution works perfectly for every application. Reflect on your specific needs before making a choice. Be prepared to adjust your strategies based on real-world performance.