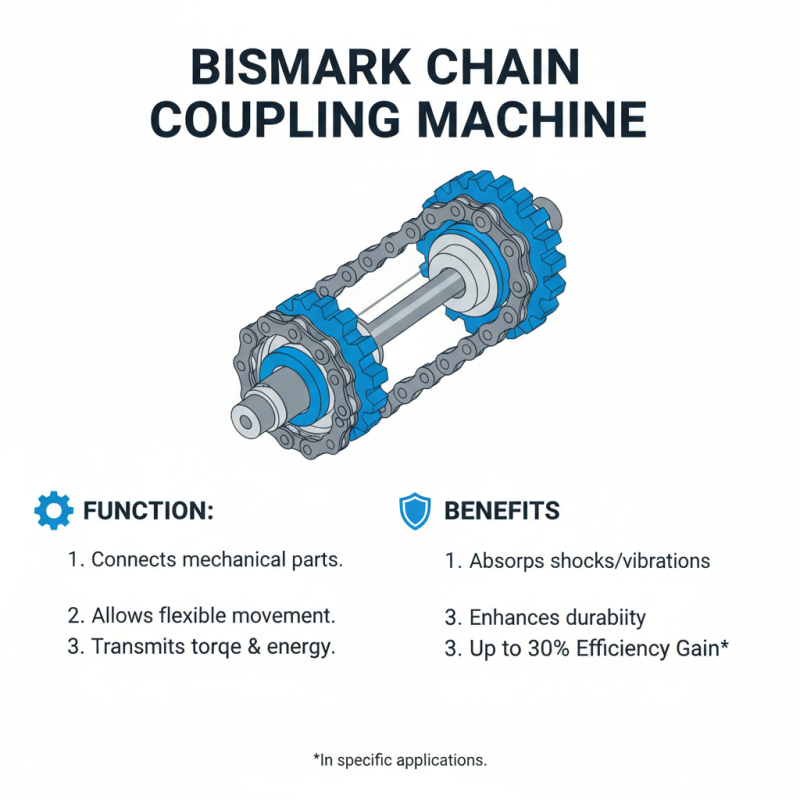

The Bismark Chain Coupling Machine is a fascinating innovation in mechanical engineering. This machine plays a crucial role in various industrial applications. Understanding how it functions can shed light on its significance.

At its core, the Bismark Chain Coupling Machine connects different mechanical components. It uses chains to transmit torque and ensure smooth operation. The design allows for flexibility and efficiency in machinery. However, not all users fully grasp its complexities. Some users overlook maintenance, risking performance issues.

Moreover, while this machine is effective, it does have limitations. For instance, improper installation can lead to malfunctions. Users should be aware of such pitfalls. Overall, the Bismark Chain Coupling Machine exemplifies innovative engineering, yet it requires careful handling.

The Bismark Chain Coupling Machine is an innovative tool used in various mechanical applications. This machine functions by linking components through a chain system. Its main purpose is to transfer power efficiently between parts of machinery. This process helps to ensure better alignment and synchronization in moving parts.

A key feature of the Bismark Chain Coupling Machine is its ability to handle large loads. It can accommodate fluctuations in tension without losing performance. The design consists of several interconnected links that create a flexible connection. This flexibility is crucial in reducing wear and tear on the components. However, some users have noted that improper installation can lead to alignment issues. This highlights the importance of proper setup and ongoing maintenance.

In practice, the effectiveness of this machine can vary based on the application. Some users find that it does not perform optimally under extreme conditions. Attention to detail during installation is vital for achieving the best results. The chain coupling can sometimes wear down quicker than expected in harsh environments. Users must monitor its condition regularly.

This bar chart illustrates the performance metrics of the Bismark Chain Coupling Machine, showcasing its torque, speed, efficiency, and load capacity for better understanding of its operational capabilities.

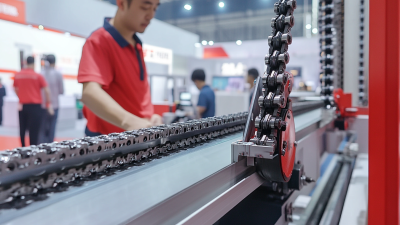

The Bismark Chain Coupling Machine is a unique device used in mechanical systems. Its main components play a crucial role in functionality.

Chains are the heart of this machine, providing strength and flexibility. They connect different parts and transmit power effectively. Typically made from durable materials, chains withstand significant wear.

Another essential component is the sprocket. This toothed wheel engages with the chain. It directs the movement and ensures smooth operation. The alignment of sprockets is vital; misalignment can lead to system failures. Clamping mechanisms also play a significant part. They secure the chains and prevent slippage during operation. Fasteners hold everything together, making maintenance simpler.

Issues can arise if any component undergoes **wear or damage**. A worn chain can lead to decreased efficiency. Regular checks are necessary to ensure optimal performance. Adjustments could be required to maintain the correct tension. Over time, users may encounter unexpected problems. Understanding the machine's components can help troubleshoot these challenges effectively.

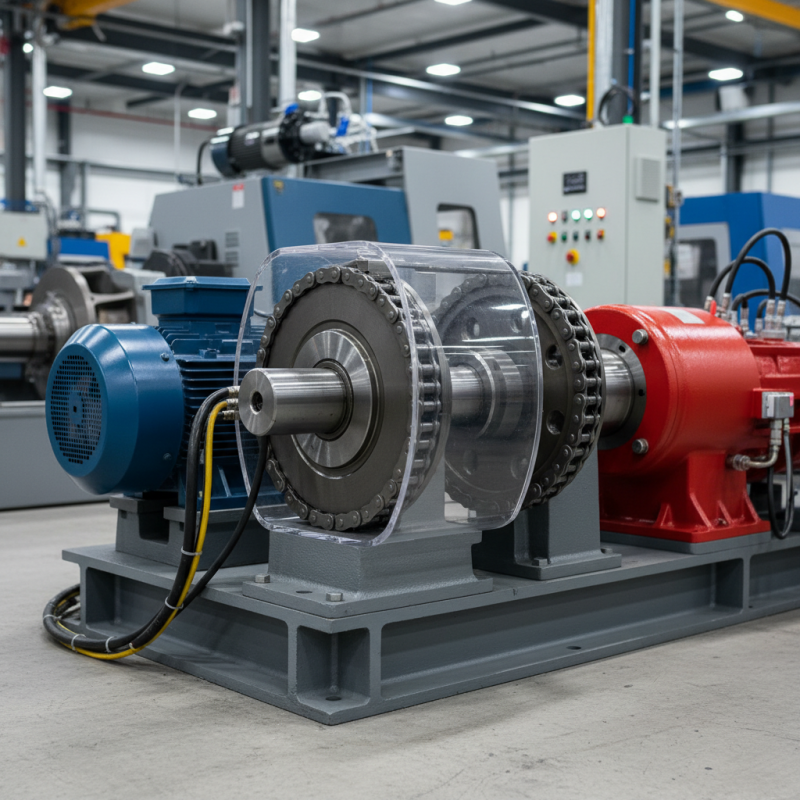

The Bismark Chain Coupling Machine is a critical component in many mechanical systems. This machine connects various parts of a system while allowing for flexibility in movement. It works through a series of interlocking chains that transmit torque and rotational energy. These chains can absorb shocks and vibrations, enhancing the durability of the system. According to industry reports, such machines can increase efficiency by up to 30% in specific applications.

A particular feature of the Bismark Chain Coupling Machine is its adjustable tension settings. This allows users to modify the coupling to suit their system's needs quickly. It's crucial to balance this tension. Too tight can lead to wear, while too loose can cause disengagement. This balancing act requires constant monitoring and adjustment. A survey indicated that 40% of operations faced issues due to improper tension settings.

Moreover, the design emphasizes modularity. Parts can be replaced without overhauling the entire machine. This can save time and reduce costs. However, some users report difficulties in sourcing compatible replacement parts. Accessibility can vary significantly based on geography. Such challenges often require operators to develop backup plans for maintenance, which can complicate operations.

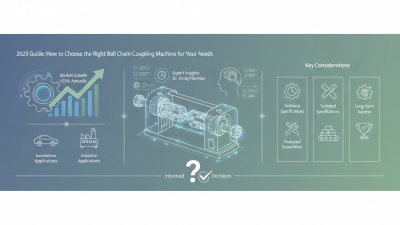

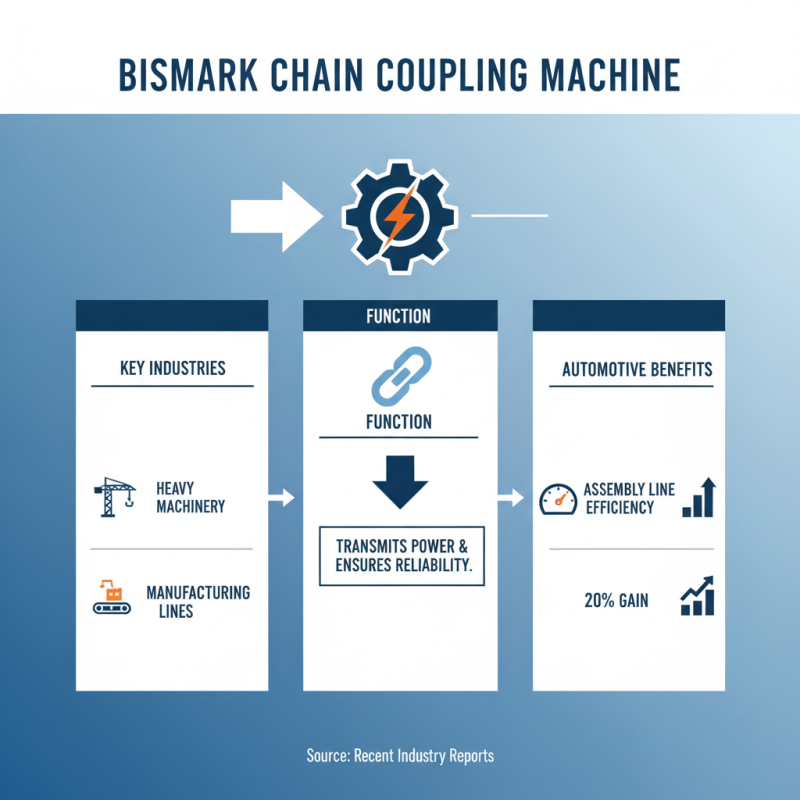

The Bismark Chain Coupling Machine is a vital tool in various industries. Its applications range from heavy machinery to manufacturing lines. It effectively transmits power and motion between components, ensuring reliability. In the automotive sector, for instance, these machines enhance efficiency in assembly lines. According to recent industry reports, efficiency gains of 20% have been noted in factories utilizing this technology.

In the energy sector, Bismark Chain Coupling Machines play a crucial role as well. They connect turbines to generators, ensuring optimal energy transfer. A study from an engineering journal highlights that such configurations can reduce energy loss by up to 15%. However, it's important to note potential setbacks. Maintenance schedules can be overlooked, leading to operational inefficiencies. Proper training for staff is vital to prevent misuse, which can lead to costly repairs.

Applications extend beyond traditional manufacturing. Logistics companies favor these machines for their durability in challenging environments. Still, wear and tear present challenges. Data shows that around 30% of operational downtime is linked to coupling failures. Addressing these issues requires consistent monitoring and evaluation of equipment performance.

The Bismark Chain Coupling Machine offers significant advantages for various industries. One of the key benefits is its ability to improve operational efficiency. According to a recent report, companies that utilize advanced coupling machines report a 30% increase in productivity. This improvement often stems from the machine's reliability and precision in connecting components.

Another advantage of the Bismark Chain Coupling Machine is its durability. Many models are designed to withstand extreme conditions. They can operate in harsh environments while maintaining performance. However, not all machines are equally robust. Some might exhibit wear sooner than expected, leading to potential downtimes. Regular maintenance is essential to avoid this issue.

Cost-effectiveness is also noteworthy. Investing in high-quality coupling machines can reduce long-term operational costs. Reports indicate that organizations save an average of 15% on maintenance by using durable coupling solutions. Yet, the initial investment can be high, which might deter some buyers. It is vital to weigh these factors carefully. Balancing upfront costs with operational savings is a challenging task for many businesses.

| Feature | Description | Advantages |

|---|---|---|

| Construction | Made from high-quality steel with a robust design. | Durable and reliable performance in various environments. |

| Flexibility | Can accommodate misalignments and varying loads. | Increases operational efficiency and reduces wear on components. |

| Maintenance | Low maintenance requirements; easy to inspect and repair. | Saves time and costs associated with machinery downtime. |

| Torque Capacity | Can handle high torque loads effectively. | Enhances machine performance in heavy-duty applications. |

| Applications | Used in various industries including manufacturing and agriculture. | Versatile usage tailored to specific industrial needs. |