In the world of jewelry making, the importance of efficient tools cannot be overstated. A "Gold Chain Machine" revolutionizes the way jewelers craft intricate designs. As industry expert John Marshall states, “A Gold Chain Machine saves time and enhances creativity.” This innovation allows artisans to produce beautiful chains with precision and speed.

Using a Gold Chain Machine brings numerous advantages. It streamlines the production process and reduces manual labor. Jewelry makers can focus on creativity rather than the tedious tasks involved in chain production. The machine also offers consistency, ensuring that each piece meets high standards. However, reliance on machinery may lead some jewelers to overlook traditional skills.

In a competitive market, balancing modern tools with craftsmanship is vital. Jewelers must reflect on how they integrate technology. The Gold Chain Machine is a valuable asset, but it shouldn’t replace the artistry behind jewelry making. Embracing both innovation and tradition can lead to stunning results in the jewelry industry.

Gold chain machines play a crucial role in jewelry production. Their efficiency impacts not only the quality but also the output. According to recent industry reports, automated machinery can increase production rates by up to 40%. This allows jewelers to meet growing market demands effectively.

Moreover, gold chain machines ensure precision in design and construction. With the advancement of technology, the margin for error has reduced significantly. Studies show that handmade chains can have up to a 5% error rate in measurement. However, automated processes can lower this to less than 1%. This shift towards machinery also addresses labor challenges, as skilled artisans become harder to find.

Despite these advantages, some jewelers express concerns about losing the personal touch. There’s a belief that handcrafted items carry more value. This may lead to a debate within the industry about balance. While machines enhance productivity, the essence of artistry should be preserved. Striking this balance is essential as the jewelry sector continues to evolve.

The jewelry-making world is evolving fast. A gold chain machine exemplifies this transformation by boosting both efficiency and speed. Traditional methods can be slow and labor-intensive. Imagine spending hours creating a single chain. With a gold chain machine, those hours can shrink dramatically.

Efficiency comes from precise automation. These machines minimize human error and ensure consistent quality. The design process becomes smoother. You can focus more on creativity rather than repetitive tasks. As the machine works, you can tackle other design projects. This multitasking ability can lead to greater productivity.

However, it's vital to strike a balance. Over-reliance on machines can diminish craftsmanship. Some artisans may miss the tactile joy of handmade pieces. There might be moments when a machine's output just doesn’t match the unique charm of handcrafting. This is a reflection worth considering as technology rapidly advances in the jewelry industry. Embracing efficiency is important, but so is maintaining a connection to the art itself.

Using a gold chain machine can significantly enhance cost-effectiveness in jewelry making. According to a report by the Jewelry Industry Council, manufacturers can save up to 30% on labor costs by automating chain production. This reduction directly impacts profitability, allowing jewelers to allocate resources to design and marketing efforts.

Furthermore, a gold chain machine streamlines the production process. Data indicates that production time can be cut in half compared to manual methods. For example, while handcrafting a chain might take hours, a machine can produce the same chain in under an hour. This efficiency is crucial for meeting customer demand and reducing wait times.

However, the initial investment in a machine can be substantial. Many small businesses struggle with this cost. Finding financing options is essential. Analyzing upfront expenses against long-term savings becomes necessary. If not approached wisely, the investment could hinder cash flow. Balancing immediate financial strain with future benefits may require careful reflection and strategy.

Using a gold chain machine offers significant advantages in improving precision and quality for jewelry making. These machines are designed to create consistent links with uniform shapes and sizes.

Each piece produced has a refined finish, which enhances the overall aesthetic of the jewelry. Precision helps avoid discrepancies that might arise from manual crafting. This means fewer adjustments and corrections, ensuring a more efficient workflow.

However, not every creation will be perfect. Sometimes, the machine might produce links that lack the desired smoothness. This could be due to various factors, including settings that need tweaking or the quality of the materials used. Jewelers often need to monitor and adjust the machine regularly. While the machine can elevate design, the human touch is still essential. Balancing technology and artisan skill is crucial for the best results. Striving for perfection involves understanding the machine's limitations and making necessary adjustments along the way.

This reflection fosters growth and enhances the quality of future creations.

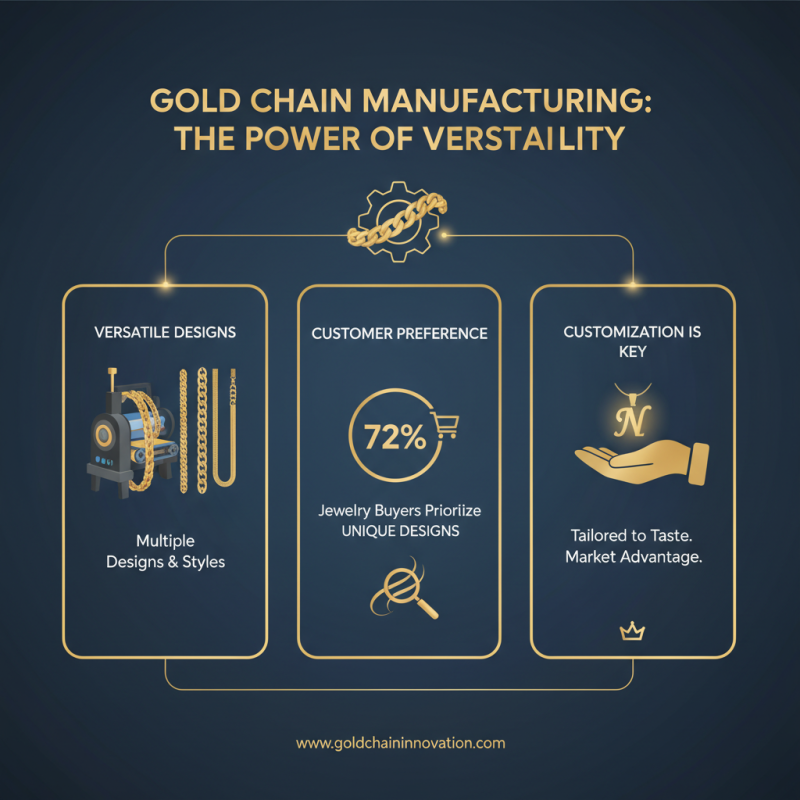

When it comes to gold chain manufacturing, versatility is a major advantage. A gold chain machine offers various designs and styles. This flexibility allows artisans to cater to diverse customer preferences. Reports indicate that 72% of jewelry buyers prioritize unique designs in their purchases. Customization is key in today’s market.

With advanced machinery, jewelers can easily switch between different chain types. This capability reduces production time and costs. For instance, a machine that produces both curb and rope chains can generate different products within hours. This adaptability also supports small businesses, allowing them to compete with larger companies. Data from industry studies reveals that smaller jewelers that embrace machine versatility can see revenue increases of up to 30%.

Despite these advantages, challenges exist. Not all machines are equally efficient or user-friendly. Some require extensive training, leading to initial downtime. Artisans may struggle with the machine's settings, impacting the final product's quality. Balancing customization with quality control is essential. Feedback from customers can provide valuable insights. The pursuit of perfection in craftsmanship while utilizing such machines can feel daunting. However, facing these challenges can ultimately lead to growth and improved offerings in gold jewelry.