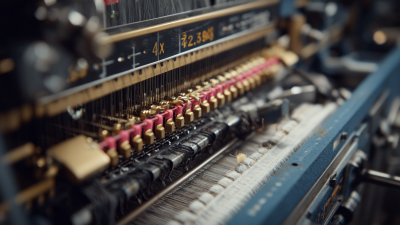

In the world of textile manufacturing, efficiency and quality are paramount. The Chopin Chain Weaving Machine stands out as a pivotal tool in this industry. Its advanced technology enhances production, offering multiple benefits to users. Many manufacturers have realized the advantages of this machine.

One significant benefit is its ability to produce intricate designs quickly. Craftsmen appreciate the detail and precision it brings. The machine reduces labor costs while increasing output. However, some users report a learning curve when first adapting to its features. They find that initial trials can be frustrating. Despite this, perseverance often leads to innovative designs and processes.

Another advantage is durability. The Chopin Chain Weaving Machine is built to last. This reliability ensures lower long-term maintenance costs. Yet, it's essential for businesses to regularly assess its performance. Regular evaluations can highlight areas for improvement. Embracing this machine can transform a manufacturing process, but reflection on usage is crucial for continued success.

The Chopin chain weaving machine offers numerous benefits that can significantly impact production efficiency and product quality. One key advantage is its precision. Reports indicate that machines like these can enhance weaving accuracy by up to 30%. This precision leads to reducing fabric defects and waste, which is crucial for maintaining profit margins in the textile industry.

Another benefit is the speed of production. Studies show that utilizing advanced weaving technology can increase output by 50% compared to traditional methods. This rapid production allows companies to respond to market demands more quickly. However, it’s essential to remember that faster doesn’t always mean better. Operators need proper training to avoid mistakes.

**Tips:** When adopting new machinery, invest in comprehensive training for staff. It minimizes errors, maximizing efficiency. Also, regularly maintain the machines. This practice enhances longevity and reliability.

Lastly, the versatility of the Chopin machine cannot be overlooked. It can produce various fabric types, catering to diverse market needs. Still, businesses should assess their specific requirements before investing. Customization may not be feasible for all operations, leading to unnecessary expenditures.

The advancement of chain weaving technology has brought about significant changes in production efficiency. Using a modern weaving machine can streamline operations like never before. These machines often feature automated functions. This helps reduce human error in the weaving process. The precision of the weave enhances overall product quality. A better product can lead to increased customer satisfaction.

However, adopting new technology comes with challenges. Training staff to operate advanced machines can be difficult. Some workers may resist the change. Adapting to new routines takes time. It is essential to address these issues. Fostering an environment that encourages learning can ease the transition. Mistakes will happen, but they can serve as valuable learning experiences.

Another advantage is the flexibility of modern machines. They can handle different chain sizes and materials. This adaptability allows manufacturers to meet varying demands. But, neglecting regular maintenance can lead to downtime. This can disrupt production schedules. Finding a balance between maintenance and operation is crucial for success. In the end, the benefits of advanced chain weaving technology can be profound, but there is always room for improvement.

Weaving is an art that requires precision. Traditional methods often lead to material waste. This is where modern weaving techniques shine. Utilizing advanced machinery can drastically reduce excess material. Every inch of fabric counts in production. Precision weaving techniques ensure that every cut is exact.

With these machines, fabric is woven seamlessly. There is less scrap material left behind. Efficient designs maximize the utilization of textiles. The outcome is not just saving resources but also improving sustainability. Fewer materials wasted means a smaller environmental footprint. However, achieving perfect precision is still a challenge.

Sometimes, small flaws occur during the weaving process. Even with advanced technology, human oversight can lead to hiccups. Reflecting on this shows that no process is flawless. Continuous improvement is essential, even in precision weaving. The goal should be to constantly refine techniques. This pursuit leads to better use of materials and less waste overall.

In textile manufacturing, product quality is paramount. A reliable weaving machine can significantly enhance this quality. It ensures tighter weaves and consistent patterns, resulting in durable fabric. Consider the precision in every thread. Machines built for this purpose effectively reduce human error. This leads to fewer defects in the final product.

Consistency is another crucial benefit. A specialized machine maintains the same tension throughout the weaving process. This uniformity ensures that each batch of fabric is identical. Yet, it’s important to note that not every machine achieves this level. Manufacturers need to continuously assess their equipment for optimal performance. Routine maintenance is vital, as wear and tear can diminish output quality. The right machine can make a difference, but reflection on its performance is always necessary.

| Benefit | Description | Impact on Quality |

|---|---|---|

| Improved Weaving Precision | Ensures tighter tolerance in fabric production. | Reduces defects and enhances durability. |

| Increased Production Speed | Outputs fabrics at a faster rate than traditional methods. | Enhances overall efficiency. |

| Consistent Fabric Quality | Maintains identical patterns and textures across batches. | Builds trust and satisfaction among clients. |

| Lower Material Waste | Optimizes yarn usage with minimal leftover. | Cost savings and sustainable practices. |

| Versatility in Designs | Capable of creating a wide variety of patterns. | Attracts diverse clientele with customized options. |

| Enhanced Operator Control | User-friendly interfaces allow for easy adjustments. | Improves operator efficiency and reduces errors. |

| Robust Machine Design | Durable construction withstands heavy use. | Longer machine lifespan leading to fewer replacements. |

| Advanced Technology Integration | Incorporates the latest tech for improved functionality. | Enhances quality through innovative processes. |

| Reduced Labor Costs | Automates processes reducing manpower needs. | Significant savings on labor expenses. |

| Better Market Competitiveness | Quicker turnaround times with higher quality. | Positions business favorably in the market. |

Using a modern chain weaving machine can lead to significant cost savings for businesses. Increased durability is one major advantage. These machines are built to last, able to withstand rigorous use. They often require fewer replacements over time. This reliability means companies can allocate funds more efficiently. Less frequent breakdowns ensure smoother operations, leading to better productivity.

Lower maintenance needs also contribute to overall savings. Maintenance schedules can be more flexible. Operators spend less time on routine checks and repairs. This is a game changer for small to medium-sized enterprises. However, companies should remain vigilant. Neglecting routine maintenance could lead to unexpected failures. Investing in training for staff can prevent such mishaps. A proactive approach to machine care is essential for maximizing benefits.

Transitioning to advanced weaving technology can be daunting, yet the potential rewards are significant. A thorough understanding of the equipment is vital. Users may face a learning curve. Emphasizing the importance of gradual adaptation can facilitate this transition. Balancing investment with proper education ensures lasting success.

The Chopin Chain Weaving Machine offers numerous advantages that significantly enhance production processes across various industries. Its advanced chain weaving technology boosts production efficiency by streamlining operations and reducing downtime. Additionally, the machine employs precision weaving techniques, effectively minimizing material waste and ensuring optimal resource utilization.

Furthermore, the Chopin Chain Weaving Machine contributes to superior product quality and consistency in textile manufacturing, which is essential for meeting market demands. Its durability translates into cost savings, as lower maintenance needs reduce operational expenses over time. Overall, the versatility of the Chopin Chain Weaving Machine makes it an invaluable asset for manufacturers looking to improve their production capabilities and maintain competitive edges in their respective markets.