In today's competitive manufacturing landscape, the adoption of advanced technologies is crucial for enhancing operational efficiency and product quality. The Box Chain Making Machine stands out as a pivotal innovation, streamlining the production process while significantly reducing labor costs. According to a recent industry report by the Global Machinery Association, businesses utilizing automated chain making solutions have observed a productivity increase of up to 45%, demonstrating the transformative power of these machines.

Industry expert Dr. Samuel Jenkins, a leading voice in manufacturing automation, states, "Integrating a Box Chain Making Machine into your production line not only optimizes resource allocation but also ensures consistent quality across large batches." His insights underscore the essential role of technological advancements in meeting market demands effectively, especially as consumer preferences shift towards customized and high-quality products.

Furthermore, the implementation of Box Chain Making Machines facilitates greater flexibility within production schedules. This adaptability positions manufacturers to respond swiftly to changing consumer needs while maintaining cost-effectiveness. As the market continues to evolve, investing in such innovative machinery is becoming increasingly indispensable for businesses aiming to stay ahead of the curve and maximize profitability.

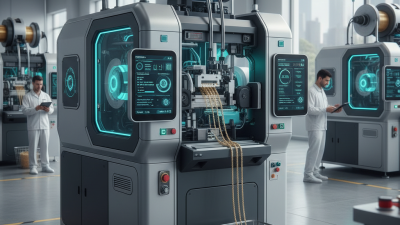

Box chain making machines have become essential tools for businesses looking to optimize production processes in various industries. One of the key features of these machines is their advanced automation capabilities, which significantly reduce manual labor and human error. According to a report by Industry Research, businesses using automated chain making machines have reported up to a 30% increase in production efficiency, allowing them to meet demand more swiftly. Automation also enables precise measurements, resulting in consistent product quality.

Another notable feature is the adaptability of box chain making machines. These machines can easily switch between different sizes and thicknesses, catering to diverse market needs without requiring extensive downtime for reconfiguration. This flexibility allows manufacturers to respond rapidly to market changes and customer preferences, maximizing their competitive edge. The capacity for real-time monitoring within these machines can also lead to improved operational insights, helping businesses identify areas for further optimization.

**Tips**: When investing in box chain making machines, consider the scalability of the equipment to meet future business needs. Additionally, training staff to operate these machines efficiently can further enhance productivity and minimize operational hiccups. Regular maintenance and updates are crucial to keeping the machines running smoothly and ensuring that businesses continue to meet production goals effectively.

| Feature | Description | Benefit |

|---|---|---|

| High Efficiency | Designed for rapid production cycles. | Increases overall output and reduces labor costs. |

| Precision Engineering | Built with high precision components. | Ensures consistent quality of products. |

| User-Friendly Interface | Intuitive controls and easy setup. | Reduces training time for operators. |

| Durable Construction | Manufactured with robust materials. | Lowers maintenance costs and extends lifespan. |

| Versatile Applications | Can produce various chain sizes and types. | Broadens product offerings, attracting more customers. |

| Energy Efficiency | Low energy consumption design. | Reduces operational costs significantly over time. |

| Automated Functions | Advanced automation technology. | Minimizes human error and increases speed. |

The adoption of box chain making machines has revolutionized the production process within the packaging industry, particularly by enhancing cost efficiency and profit margins. According to a report by the International Society of Automation, companies that implemented automated systems for manufacturing saw labor costs reduced by up to 30%. This significant decline allows businesses to reallocate resources toward innovation and improvement, enhancing overall operational efficiency.

Moreover, automating box chain production leads to higher output rates and reduced cycle times. The report further indicates that automation can boost production capacity by 45%, enabling manufacturers to meet increasing market demands without the need for substantial workforce expansion. This not only helps in scaling operations but also increases profitability, as businesses can produce more with less, ultimately driving down unit costs and improving margins.

The initial investment in automated machinery is often recouped within a few years due to these savings, solidifying the financial benefits of embracing this technology in box chain production.

The utilization of box chain making machines significantly enhances product quality through precision engineering in the manufacturing process. According to a report by the International Organization for Standardization (ISO), companies that implement advanced manufacturing technologies, such as precision machinery, can improve their production accuracy by up to 30%. This level of precision ensures that each component meets the desired specifications, minimizing defects and maximizing the consistency of the final product.

Moreover, the integration of automated box chain making machines allows for increased efficiency in production cycles. A study by the National Institute of Standards and Technology (NIST) indicates that automation can lead to a reduction of operational costs by approximately 25% while simultaneously increasing output rates. This efficiency not only boosts profit margins but also enables manufacturers to focus more on quality control procedures, ensuring that every box chain produced meets rigorous industry standards.

Furthermore, precision engineering in manufacturing translates into superior end-use performance for products. Research indicates that high-quality box chains manufactured with state-of-the-art machinery exhibit improved load-bearing capacities and longer lifespan when compared to those produced using outdated methods. This focus on quality helps businesses build trust and credibility with their customers, ultimately leading to enhanced market competitiveness.

The flexibility and customization options provided by box chain making machines significantly enhance their utility for businesses in various sectors. According to the market report by Grand View Research, the global machine manufacturing industry is projected to reach USD 6.7 trillion by 2025, and companies that leverage advanced machinery like box chain making machines are better positioned to tap into this growth. These machines allow for a wide range of designs tailored to specific customer requirements, enabling manufacturers to produce chains that meet niche market demands.

Moreover, the adaptability of these machines in terms of material variations and production sizes makes them a vital asset for businesses aiming to diversify their product offerings. The International Market Analysis Research and Consulting Group (IMARC) notes that customization capabilities can lead to a 20-30% increase in customer satisfaction, as clients increasingly seek personalized solutions. Furthermore, box chain making machines can be adjusted for different box chain specifications, from size to shape, which allows manufacturers to respond swiftly to changing market trends without the need for significant retooling or downtime. This level of customization not only enhances competitiveness but also boosts profitability by reducing excess inventory and aligning production closely with consumer preferences.

The adoption of box chain making machines has revolutionized production processes for businesses across various industries. One of the most significant advantages of these machines is their ability to streamline operations. By automating key aspects of the chain-making process, companies can minimize manual intervention, leading to smoother workflows and increased efficiency. This automation reduces the likelihood of errors, ensuring that products meet quality standards consistently. As a result, businesses can focus their resources on other critical tasks, fostering an environment conducive to innovation and growth.

In addition to enhancing efficiency, box chain making machines significantly reduce lead times. Traditional methods often involve lengthy production cycles, which can delay delivery and affect customer satisfaction. By implementing advanced machinery, businesses can expedite their production timelines, allowing them to respond quickly to market demands. Shorter lead times not only improve customer relations but also enable companies to adapt to changing trends more effectively. This agility in production is essential for maintaining a competitive edge in today’s fast-paced market.