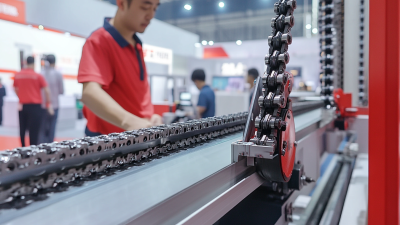

In the rapidly evolving landscape of modern manufacturing, the Box Chain Coupling Machine has emerged as a vital player in enhancing operational efficiency and flexibility. According to a report by Grand View Research, the global manufacturing execution system market is expected to reach USD 20.32 billion by 2027, reflecting a growing need for sophisticated machinery that enhances production lines.

The Box Chain Coupling Machine, with its robust design and adaptable features, offers manufacturers a significant advantage by providing smoother power transmission and improved reliability under varying load conditions. Research from the National Institute of Standards and Technology (NIST) indicates that integrating advanced coupling technologies can reduce downtime by up to 30%, underscoring the Box Chain Coupling Machine's role in minimizing operational disruptions. As the industry increasingly shifts towards automation and smart manufacturing solutions, the strategic adoption of Box Chain Coupling Machines is pivotal for companies aiming to boost their productivity and remain competitive.

The Box Chain Coupling Machine, with its robust design and adaptable features, offers manufacturers a significant advantage by providing smoother power transmission and improved reliability under varying load conditions. Research from the National Institute of Standards and Technology (NIST) indicates that integrating advanced coupling technologies can reduce downtime by up to 30%, underscoring the Box Chain Coupling Machine's role in minimizing operational disruptions. As the industry increasingly shifts towards automation and smart manufacturing solutions, the strategic adoption of Box Chain Coupling Machines is pivotal for companies aiming to boost their productivity and remain competitive.

In modern manufacturing, minimizing downtime is crucial for enhancing productivity and profitability. Box chain coupling machines have emerged as a transformative solution in this regard. According to a report by the Manufacturing Performance Institute, reducing unplanned downtime can lead to a productivity increase of up to 20%. Box chain systems, with their robust design and efficient power transmission, help manufacturers achieve this goal by streamlining operations and ensuring that machinery runs smoothly.

These machines are particularly effective at minimizing maintenance requirements, which directly impacts downtime. Data from the Industrial Maintenance Association indicates that maintenance costs can consume 30% of a manufacturing budget. However, the modular design of box chain coupling machines facilitates easier replacement of components, allowing for quicker repairs and a decrease in the frequency of maintenance, thereby maximizing operational uptime. Additionally, the high durability of these machines means less frequent replacements, resulting in cost savings and increased output. By investing in box chain coupling technologies, manufacturers can create more efficient production lines while significantly reducing the risk of delays due to mechanical failures.

The adoption of Box Chain Coupling Machines in modern manufacturing has a significant impact on Overall Equipment Effectiveness (OEE), a key metric that assesses the efficiency of manufacturing processes. According to a report from the Manufacturing Performance Institute, companies that implement advanced coupling technologies can see OEE improvements of up to 30%. This increase is primarily due to enhanced reliability and reduced downtime, allowing for smoother production flows and higher output rates.

Furthermore, the flexibility of Box Chain Coupling Machines facilitates quicker adjustments to varied production requirements, thus reducing changeover times. The Aberdeen Group cited that organizations using these machines can reduce setup times by as much as 25%, which is crucial in today’s fast-paced market. Enhanced adaptability not only boosts OEE but also contributes to lean manufacturing principles, minimizing waste and optimizing resource usage. With better coupling systems in place, manufacturers can achieve a higher return on investment and maintain competitive advantage in a challenging economic landscape.

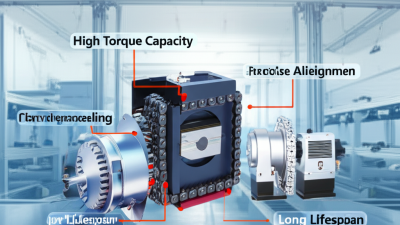

Box chain coupling machines are revolutionizing the landscape of modern manufacturing by significantly enhancing precision and accuracy in production processes. These machines utilize advanced technology to create seamless connections between components, minimizing backlash and ensuring that movements are synchronized with pinpoint accuracy. According to a recent industry report, manufacturers that have integrated box chain coupling systems have observed a reduction in production errors by up to 30%, ultimately leading to improved product quality and customer satisfaction.

In parallel, the advent of artificial intelligence (AI) is further driving the efficiency of manufacturing operations. AI algorithms analyze production data in real-time, allowing for rapid adjustments that optimize performance. For instance, when combined with box chain coupling technology, AI can predict maintenance needs and identify potential failures before they occur, enhancing not only precision but also operational reliability. A study by a leading manufacturing research firm highlights that AI, when integrated with precision machinery, can produce a 20% increase in overall equipment effectiveness (OEE). This synergy between box chain coupling and AI technologies ensures that modern manufacturing processes are not only efficient but also aligned with the growing demands for quality and adaptability in the marketplace.

The implementation of box chain couplings in modern production lines offers significant cost advantages that can enhance overall manufacturing efficiency. One of the primary benefits is their durability and low maintenance requirements, which reduce downtime and repair costs. As manufacturing processes become increasingly automated, the reliability of components like box chain couplings can lead to substantial long-term savings. Businesses that incorporate these systems often experience a smoother workflow, allowing for greater output without the necessity of extensive machinery investments.

Tip: When considering box chain coupling machines for your production line, assess your specific operational needs to ensure compatibility with existing systems. This proactive approach can maximize your return on investment.

Moreover, box chain couplings facilitate the use of standardized parts, which can simplify inventory management and procurement. This standardization can lead to bulk purchase discounts, further cutting costs. Additionally, their ability to efficiently transmit power and accommodate high loads means fewer replacements and a longer lifespan, making them a cost-effective choice in the long run.

Tip: Regularly review your manufacturing processes to identify areas where box chain couplings can be integrated for enhanced efficiency. Small adjustments can yield significant improvements in cost and productivity.

The use of Box Chain Coupling Machines in manufacturing operations presents significant sustainability benefits that are increasingly crucial in today’s eco-conscious world. These machines enhance manufacturing efficiency by optimizing the production process and reducing energy consumption. According to industry reports, machinery upgrades, including the adoption of Box Chain Coupling Systems, can lead to energy savings of up to 30% in operations. This is largely due to their innovative design that minimizes friction and maximizes power transfer, allowing for smoother and more efficient production flows.

Integrating Box Chain Coupling Machines not only elevates operational performance but also contributes to a greener manufacturing footprint. Utilizing advanced technologies, these machines align with the principles of sustainable manufacturing. For instance, by incorporating recyclable materials and energy-efficient components, manufacturers can significantly reduce waste. Additionally, the durability of Box Chain components implies longer service life, resulting in lowered manufacturing costs over time.

Tips: To further enhance sustainability in conveyor systems, manufacturers should regularly schedule maintenance checks to ensure optimal performance and energy efficiency. Additionally, consider incorporating artificial intelligence in predictive maintenance to minimize downtime and improve resource allocation. Embracing these technologies can propel businesses toward more sustainable practices while maintaining productivity.