The Ball Chain Coupling Machine is a critical innovation in manufacturing. In 2026, it has evolved significantly. This machine enhances efficiency in various applications, from automotive parts to industrial equipment.

Manufacturers have embraced this technology. It allows for precise connections between components. As a result, production speeds have increased. However, not all operations fully utilize its potential. Some users struggle to adapt to new features.

Understanding the machine's innovations is vital. Many machines have advanced designs, but practical applications often lag behind. This raises questions about user training and integration. The balance between innovation and effective use remains a challenge.

The ball chain coupling machine sector is witnessing remarkable advancements in 2026. Emerging technologies are enhancing efficiency and versatility in manufacturing processes. According to recent industry reports, around 70% of companies are adopting automated ball chain systems. This shift is driven by the need for precision in production and reduced labor costs.

New materials are being integrated into these machines. Lightweight alloys and advanced polymers are increasing durability and performance. Some reports indicate that these innovations can lead to a 30% reduction in downtime. However, not all manufacturers are keeping pace. A gap exists where smaller companies struggle to compete due to limited resources.

Tips: Regularly evaluate your equipment’s performance. Measure efficiency every quarter. Small improvements can lead to substantial gains over time. Embrace new technologies cautiously. Testing innovations on a small scale may reveal insights before full implementation. As the market evolves, remaining adaptable is essential.

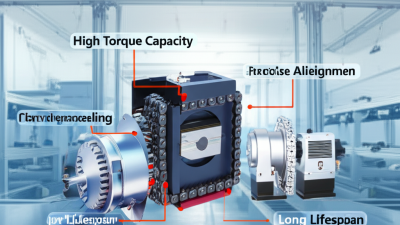

The ball chain coupling design has undergone significant innovation recently. Advanced materials have emerged, enhancing durability and functionality. Polymer composites are now common. They offer lightweight solutions while maintaining strength. These materials can resist corrosion and impact damage. This has improved the performance of various machines.

In addition, the integration of advanced machining techniques has raised the precision of ball chain couplings. These techniques produce parts with tighter tolerances. The result is a smoother operation. However, this precision can lead to challenges. Slight deviations could affect performance. Engineers must pay attention to every detail during production.

Furthermore, customization options are becoming more prevalent. Manufacturers can tailor designs to specific applications. This caters to diverse industry needs. Yet, more options can lead to confusion. Users may struggle to choose the right coupling. This highlights the need for better guidance in product selection. Understanding the new innovations is crucial in maximizing efficiency.

| Innovation Type | Description | Material Used | Applications |

|---|---|---|---|

| Advanced Lubrication | New lubrication systems that enhance performance and reduce wear. | Synthetic oils and advanced coatings | Automotive, Aerospace |

| Smart Couplings | Integration of IoT sensors for real-time monitoring and analysis. | High-strength plastics and metals | Manufacturing, Robotics |

| Enhanced Durability | Innovative materials that improve resistance to corrosion and fatigue. | Alloyed metals, coated materials | Construction, Heavy Machinery |

| Modular Design | Versatile coupling configurations for various applications. | Lightweight composites | Consumer Products, Electronics |

| Noise Reduction Technology | Innovations aimed at minimizing operational noise in machinery. | Acoustic dampening materials | Home Appliances, Automotive |

The rise of Industry 4.0 has dramatically reshaped many manufacturing processes, including ball chain coupling machines. These machines now benefit from automation and data exchange. This shift leads to enhanced efficiency and precision in production lines. Manufacturers are leveraging smart technology to minimize human errors. However, this transition is not without its challenges.

Incorporating smart sensors can help optimize machine performance. However, these sensors can sometimes malfunction. Regular maintenance is crucial to ensure their accuracy. Relying solely on technology can result in oversight of basic operational principles. The human touch still matters for troubleshooting unexpected issues.

Consider training staff on both manual and automated systems. Employees should understand the technology. Yet, they should also remember traditional methods. This dual knowledge fosters more adaptable teams. As machines become smarter, it's essential not to lose sight of fundamental skills. Balance is key in embracing innovations while retaining essential expertise.

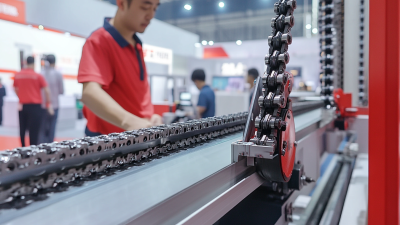

Ball chain coupling machines play a vital role in various manufacturing sectors. These machines provide efficient and reliable connections necessary for the operation of complex machinery. They are widely used in industries such as automotive, aerospace, and packaging. The demand for these systems continues to grow as manufacturers seek to enhance productivity through automation.

In the automotive sector, ball chain couplings are crucial for connecting multiple components. They ensure the smooth transmission of power between gears and engines. In aerospace, these machines help in the assembly of aircraft parts, where precision is key. The packaging industry also benefits significantly. Automated systems rely on these couplings to operate conveyor belts and sorting machines.

Tips: When considering ball chain coupling machines, evaluate their size and compatibility with existing systems. Regular maintenance is essential to prevent wear and tear. Be mindful of potential challenges, like misalignment, which can lead to inefficiency. Testing different coupling options can uncover solutions to improve your processes. Experimentation may reveal surprising results.

The ball chain coupling machine market is experiencing notable growth. Innovations drive this trend, enhancing efficiency and productivity. The demand for these machines in various industries is rising. Companies are looking for ways to streamline operations. This surge is changing how businesses approach coupling solutions.

Market projections show a steady increase. Many sectors, from automotive to aerospace, are adopting these technologies. Features such as automation and precision are in high demand. However, there are challenges. Not all manufacturers can keep up with rapid advancements. There may be a skills gap in the workforce to handle new technology.

Sustainability is becoming a priority. Many companies seek eco-friendly solutions for coupling machines. They aim to minimize waste and energy usage. The industry is still figuring out how to balance innovation with environmental responsibility. Some machines may fall short in this area. Continuous improvement in design and materials is necessary to meet these demands.