In the rapidly evolving landscape of manufacturing, choosing the right Ball Chain Coupling Machine is crucial for optimizing productivity and efficiency. According to the latest industry report by the Machinery Manufacturing Association, the market for coupling machines is projected to grow by 15% annually over the next five years, driven by increasing demand in automotive and industrial applications. As businesses strive to maintain a competitive edge, understanding the key features and specifications of these machines becomes essential.

Industry expert Dr. Emily Hartman, a leading authority in mechanical engineering, emphasizes the importance of this selection process: "Investing in the right Ball Chain Coupling Machine can significantly enhance production capabilities and reduce downtime." Her insights reflect the growing recognition that the choice of machinery directly impacts overall operational performance.

As we delve into the intricacies of selecting a Ball Chain Coupling Machine, this guide aims to provide comprehensive insights and practical considerations that will assist manufacturers in making informed decisions. From understanding technical specifications to assessing production needs, navigating this critical choice is fundamental for long-term success in the manufacturing sector.

Ball chain couplings are essential components widely used in various mechanical systems to transmit torque and accommodate misalignments between shafts. Defined as a flexible connector, these couplings consist of a series of balls linked together by a chain, allowing them to effectively handle axial and radial loads. The unique design facilitates smoother operation, which is crucial in applications that demand high precision, such as robotics, conveyor systems, and automotive assemblies.

According to a report by MarketsandMarkets, the global market for coupling devices, including ball chain couplings, is expected to grow significantly, with a projected annual growth rate of 5.2% from 2023 to 2028. This growth underscores the increasing demand for reliable and efficient coupling solutions in various industries. The ability of ball chain couplings to reduce vibration and noise further enhances their appeal, making them suitable for applications in automation and material handling where performance reliability is paramount. Understanding the specific needs of your application—such as load capacity, operating environment, and desired flexibility—will guide you in selecting the appropriate ball chain coupling to optimize operational efficiency.

| Feature | Description | Applications | Recommended Capacity |

|---|---|---|---|

| Machine Type | Automatic, Semi-Automatic, Manual | Industrial manufacturing, DIY projects | 100-1000 units/hour |

| Power Requirement | Electric, Pneumatic | Assembly lines, custom fabrication | 0.5-5 HP |

| Material Compatibility | Metal, Plastic, Steel | Jewelry making, mechanical parts | Varies based on material strength |

| Control Options | Manual, CNC, PLC | Precision engineering, automated systems | Optional based on features |

| Safety Features | Emergency stop, Safety guards | Industrial safety standards | All capacities |

| Maintenance Needs | Regular lubrication, part checks | Longevity and efficiency | Scheduled every 500 hours |

When selecting a ball chain coupling machine, understanding the key specifications is crucial to meet your operational needs effectively. One of the primary specifications to consider is the machine’s production speed. According to a recent industry report, machines capable of producing up to 900 pieces per minute can significantly increase efficiency, especially for high-volume manufacturing environments. In contrast, slower machines may suffice for smaller production runs where precision is paramount.

Another essential factor is the coupling mechanism type. Some machines offer a dual-coupling design that enhances versatility, allowing for various ball chain sizes and materials. Data suggests that manufacturers using multi-functional machines can optimize their production processes by reducing setup times and costs associated with machine changeovers. Additionally, the adjustability of the machine settings is vital; a high degree of customization can lead to improved product quality and reduced waste, aligning with industry best practices in lean manufacturing.

Finally, the durability and maintenance requirements of the machine are fundamental considerations. An analysis in a recent market study indicated that machines with better material construction and design can reduce downtime by 20-30%, which is critical for maintaining consistent output. Ensuring that the chosen ball chain coupling machine is robust and user-friendly is essential for long-term operational success, making it a wise investment for any manufacturing facility.

When selecting the right ball chain coupling machine, a comparative analysis of leading brands can provide invaluable insights into performance, durability, and cost-effectiveness. Each manufacturer offers unique features and specifications that cater to different production needs. For instance, some machines excel in speed and efficiency, making them ideal for high-volume production, while others prioritize precision and versatility, valuable for custom or low-volume applications. Evaluating these aspects helps operators make informed decisions that align with their operational goals.

Additionally, assessing customer feedback and industry reviews can highlight the reliability of each brand's machinery. Users often report on ease of use, maintenance requirements, and customer support, further guiding potential buyers. For instance, while one brand may offer advanced technology that enhances production rates, another may stand out for its user-friendly interface and less frequent breakdowns. Ultimately, a thorough examination of these comparative aspects can lead to a more strategic investment in ball chain coupling machinery, ensuring that the chosen model meets both current and future production demands.

When selecting a ball chain coupling machine, evaluating its production capacity is crucial. The machine size will directly influence how efficiently your operations run, making it essential to analyze your manufacturing needs thoroughly. Begin by assessing your current production volume and future growth projections. A machine that is too small may cause bottlenecks, while one that is too large may lead to unnecessary costs and space utilization.

Next, consider the specifications of the machine that align with your production goals. Take into account factors such as the speed of operation, the complexity of the coupling production, and the types of materials you intend to work with. It’s also beneficial to evaluate the operational scalability of the machine, ensuring it can adapt to increased demand without requiring significant modifications or additional investments. By balancing these considerations, you can make an informed decision that optimally meets your production capacity needs.

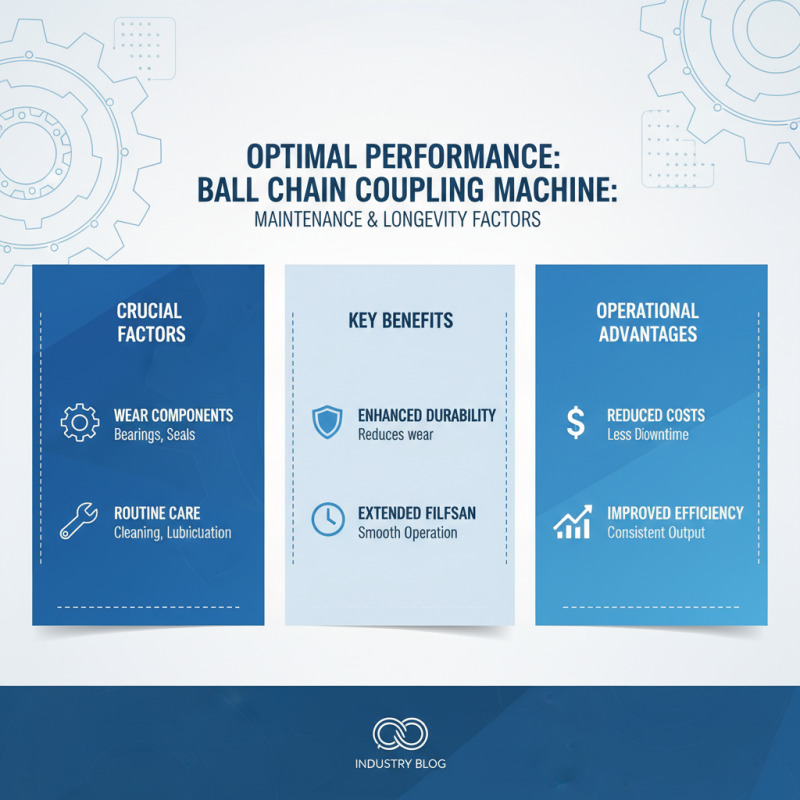

When selecting a ball chain coupling machine, understanding the factors that influence maintenance and longevity is crucial for ensuring optimal performance and reducing operational costs. Regular maintenance routines involve inspecting wear components, such as bearings and seals, which directly affect the machine’s durability. Implementing a schedule for cleaning and lubrication not only enhances efficiency but also prevents premature wear, allowing the machine to operate smoothly over an extended period.

Another essential aspect of machine longevity lies in the quality of the materials used in the construction of the ball chain coupling machine. Machines made from high-grade materials tend to withstand harsh industrial environments better, reducing the frequency of repairs and downtime. Additionally, environmental considerations, such as temperature and humidity levels in the workspace, can significantly impact machine performance. Choosing a machine that is designed to operate optimally under varying conditions will contribute to its durability and overall lifespan, ultimately benefiting your operations in the long run.